Solid-state battery adoption will happen this decade, and cells could be cheaper than liquid based cells.

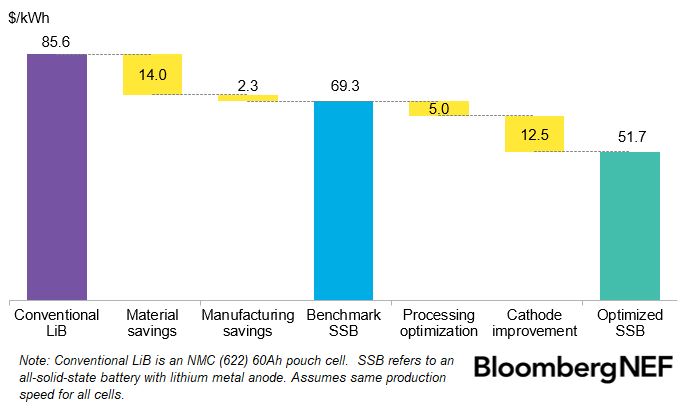

$85.6/kWh - Liquid based NMC (622)

$69.3/kWh - Solid electrolyte, NMC (622), lithium metal

$51.7/kWh - Solid electrolyte, next gen. cathode, Li metal

Thread

#battchat

$85.6/kWh - Liquid based NMC (622)

$69.3/kWh - Solid electrolyte, NMC (622), lithium metal

$51.7/kWh - Solid electrolyte, next gen. cathode, Li metal

Thread

#battchat

At the end of 2020, @BloombergNEF adapted its BattMan model to integrate solid-state cells.

At scale with developed supply chains, solid-state cells could be manufactured for 80% of the cost of liquid cells - with the same cathode.

When optimised they could be 40% cheaper...

At scale with developed supply chains, solid-state cells could be manufactured for 80% of the cost of liquid cells - with the same cathode.

When optimised they could be 40% cheaper...

A conventional cell is an 60Ah NMC (622) pouch cell manufactured in todays facilities.

Benchmark SSB is 60Ah NMC (622) pouch type solid state battery, produced on manufacturing lines of the same speed as our conventional cell. Using Lithium metal anode foil.

Benchmark SSB is 60Ah NMC (622) pouch type solid state battery, produced on manufacturing lines of the same speed as our conventional cell. Using Lithium metal anode foil.

Optimized SSB includes new cathode materials with higher voltages that can be used with solid electrolytes.

The biggest cost savings come from a reduction in the active and inactive materials used and changes to the manufacturing process

The biggest cost savings come from a reduction in the active and inactive materials used and changes to the manufacturing process

There are many approaches to producing solid-state cells, we only looked at one approach.

Electrode thickness, electrolyte thickness, lithium foil thickness and cost are key to achieving these costs.

There are also barriers to manufacturing these cells that need to be overcome.

Electrode thickness, electrolyte thickness, lithium foil thickness and cost are key to achieving these costs.

There are also barriers to manufacturing these cells that need to be overcome.

Solid-state does not mean liquid based cells are not relevant any more, and as @Tesla has outlined the cost of liquid based systems can also be dramatically reduced.

in reality both systems will compliment each other helping to open up many new areas that can be electrified!

in reality both systems will compliment each other helping to open up many new areas that can be electrified!

Its is companies like @SolidPowerInc, @QuantumScapeCo , @ProLogium, @Ilikaplc, @IonicMaterials, @ToyotaMotorCorp, @SAMSUNG_SDI, CATL to name a few that are helping make this a reality

@BloombergNEF client? Check it out -> bnef.com/insights/25061

@BloombergNEF client? Check it out -> bnef.com/insights/25061

• • •

Missing some Tweet in this thread? You can try to

force a refresh