Process Improvement - The basics

Process improvement means

- it costs less to run your operation

- there are few mistakes

- it takes less time to run your business each day

- you can take on more customers without investing in more resources

Process improvement means

- it costs less to run your operation

- there are few mistakes

- it takes less time to run your business each day

- you can take on more customers without investing in more resources

For the business owner this means:

- more cash

- less stress and fires

- less time in the business

So how do you do it?

- more cash

- less stress and fires

- less time in the business

So how do you do it?

While there are countless complex and innovative ways to carry out process improvement, many small business owners can start to see significant improvement with just a little work.

I'll walk you through a basic method here

I'll walk you through a basic method here

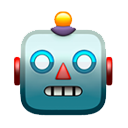

1. List your linear production process

How do you create value for your customers?

What is the process to go from no client to service/product delivered and revenue collect?

Products and Services have a linear process... many have multiple

Just pick one for now.

How do you create value for your customers?

What is the process to go from no client to service/product delivered and revenue collect?

Products and Services have a linear process... many have multiple

Just pick one for now.

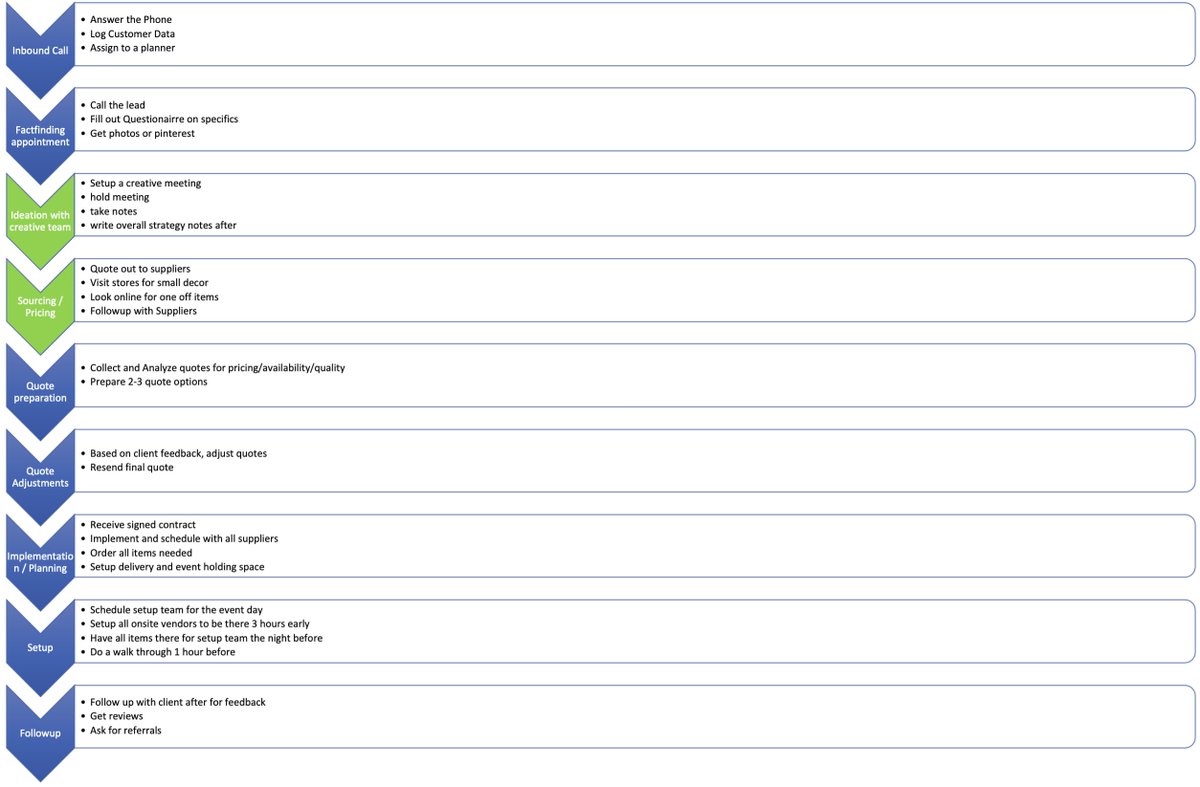

For an event company this might be something like:

1. Inbound Call

2. Factfinding appointment

3. Ideation with creative team

4. Sourcing / Pricing

5. Quote preparation

6. Quote Adjustments

7. Implementation / Planning

8. Setup

9. Followup

1. Inbound Call

2. Factfinding appointment

3. Ideation with creative team

4. Sourcing / Pricing

5. Quote preparation

6. Quote Adjustments

7. Implementation / Planning

8. Setup

9. Followup

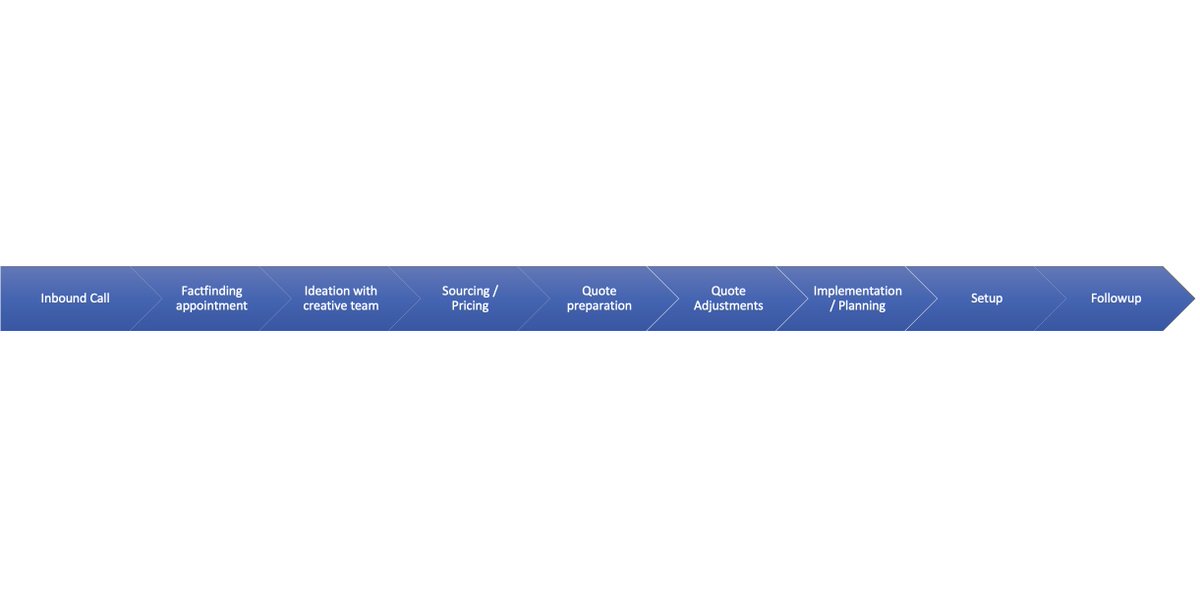

2. For each one, list out the individual components involved.

What are the activities required to carry this out?

What are the activities required to carry this out?

3. Find where you differentiate yourself and add value.

Where is it that you have an advantage? In our example, we'll say that we have an advantage because of our creative team and our supplier connections.

Where is it that you have an advantage? In our example, we'll say that we have an advantage because of our creative team and our supplier connections.

4. Now review areas that are not currently (or could be) sources of competitive advantage.

Where are things done with no human judgment needed?

What are alternative ways to do things that don't take time, money, or people?

Where are things done with no human judgment needed?

What are alternative ways to do things that don't take time, money, or people?

Ex

a. Questionnaire and pinterest/photo share could be done partially with a survey, and then lower the call time to discuss specifics

b. Automate assignment based on skill, event type matching, and current workload.

c. Use quoting software for automated follow-up to suppliers

a. Questionnaire and pinterest/photo share could be done partially with a survey, and then lower the call time to discuss specifics

b. Automate assignment based on skill, event type matching, and current workload.

c. Use quoting software for automated follow-up to suppliers

In this case, the biggest opportunity for process streamlining was client onboarding.

Two calls, the second which was very long and the first which required a lot of data entry.

We reduced this to 1 call, and a series of onboarding emails and a few forms.

Two calls, the second which was very long and the first which required a lot of data entry.

We reduced this to 1 call, and a series of onboarding emails and a few forms.

By the time the call happened:

- We already had all the data

- It was entered into our CRM

- The planners had ideas and had more meaningful (and shorter) conversations

- The close rate was higher

Data completeness 👆 Time taken 👇

- We already had all the data

- It was entered into our CRM

- The planners had ideas and had more meaningful (and shorter) conversations

- The close rate was higher

Data completeness 👆 Time taken 👇

5. How can you increase your advantage and scalability in your areas of strength?

The two longest tenured planners had a large knowledge of suppliers, quality, pricing, etc.

We turned this into an app with a database full of tagged and organized suppliers.

The two longest tenured planners had a large knowledge of suppliers, quality, pricing, etc.

We turned this into an app with a database full of tagged and organized suppliers.

With the application on the phone and internet, all planners (even temp or new) could quote with about 80% effectiveness as the planners with years of experience and connections.

6. If you have multiple lines of business or customer segments, do value changes for them too.

Put similar sections under each other.

If multiple customer types need a creative meeting, then put those under each other in the diagram.

Which sections can you combine?

Put similar sections under each other.

If multiple customer types need a creative meeting, then put those under each other in the diagram.

Which sections can you combine?

7. Now look at individual steps under each section.

Are their steps that you can combine together?

Followup had:

- Call to get clients feel/feedback

- Email to get rating

- Another Call for referrals

Are their steps that you can combine together?

Followup had:

- Call to get clients feel/feedback

- Email to get rating

- Another Call for referrals

We created an automated flow that:

- asked for feedback,

- immediately sent them to a rating site based on their feedback and scores,

- and then asked for referrals for immediate cash back on their last event.

No calls, more referrals, great ratings.

- asked for feedback,

- immediately sent them to a rating site based on their feedback and scores,

- and then asked for referrals for immediate cash back on their last event.

No calls, more referrals, great ratings.

8. Look for areas outside of your strength that can be outsourced or automated.

We created a full checklist for all aspects that need to be in place for a successful and on-time setup.

What is the entire list of things to verify for a successful setup?

We then had virtual assistants implement setups.

What is the entire list of things to verify for a successful setup?

We then had virtual assistants implement setups.

The VAs would

- Order all items in quote to the suppliers we chose

- Set up delivery for the correct dates

- Verify a few days beforehand with deliveries, food, staff, etc.

- Schedule our staff for setup times

This went from approx 10 hours down to 20 mins through VAs.

- Order all items in quote to the suppliers we chose

- Set up delivery for the correct dates

- Verify a few days beforehand with deliveries, food, staff, etc.

- Schedule our staff for setup times

This went from approx 10 hours down to 20 mins through VAs.

There are lots of ways to improve processes, this is an easy one.

There are far better ways that I and others utilize, but the point here is that it doesn't need to be hard.

List your steps, then find where to eliminate, automate, combine, outsource.

There are far better ways that I and others utilize, but the point here is that it doesn't need to be hard.

List your steps, then find where to eliminate, automate, combine, outsource.

• • •

Missing some Tweet in this thread? You can try to

force a refresh