The issues that @fortisanalysis founder, @man_integrated spoke about recently piece on why the USA may never recover from the current supply chain disruptions have a historical analog in WW2 military supply chains.

That will be this thread's subject

1/

That will be this thread's subject

1/

https://twitter.com/RealVision/status/1456642135923568644

Intercontinental logistics is never easy. Even more so when there is a thinking enemy of the other side shooting holes in them.

Yet for all that, the US never got the single most important piece right the clearing cargo through ports & beaches.

See the WW2 D-Day example.

2/

Yet for all that, the US never got the single most important piece right the clearing cargo through ports & beaches.

See the WW2 D-Day example.

2/

In the Pacific theaters, it was far worse.

The tyranny of distance, no/poor infrastructure, bureaucracy, and inter-service politics were bigger foes than the Japanese.

3/

The tyranny of distance, no/poor infrastructure, bureaucracy, and inter-service politics were bigger foes than the Japanese.

3/

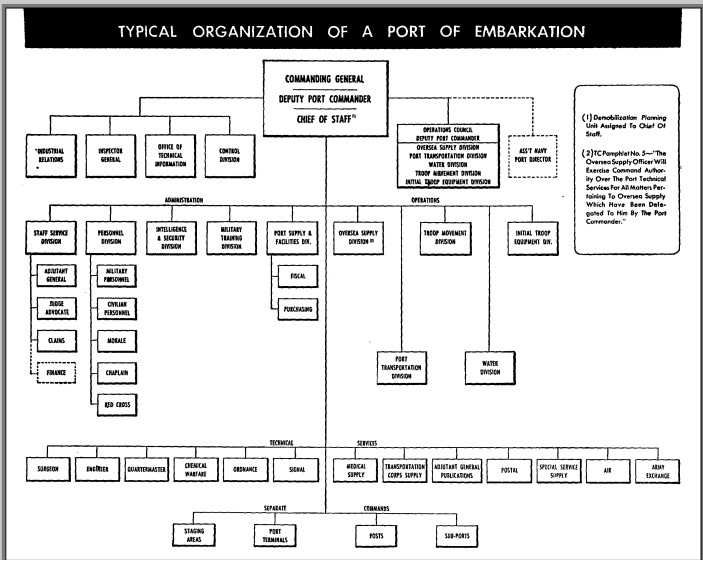

It also didn't help that the San Francisco Port of Embarkation was the most dysfunctional of WW2.

In addition to a 100 times increase in size & people, it calved off POE in Los Angeles, Seattle Portland, & Prince Rupert.

4/

nps.gov/articles/000/t…

In addition to a 100 times increase in size & people, it calved off POE in Los Angeles, Seattle Portland, & Prince Rupert.

4/

nps.gov/articles/000/t…

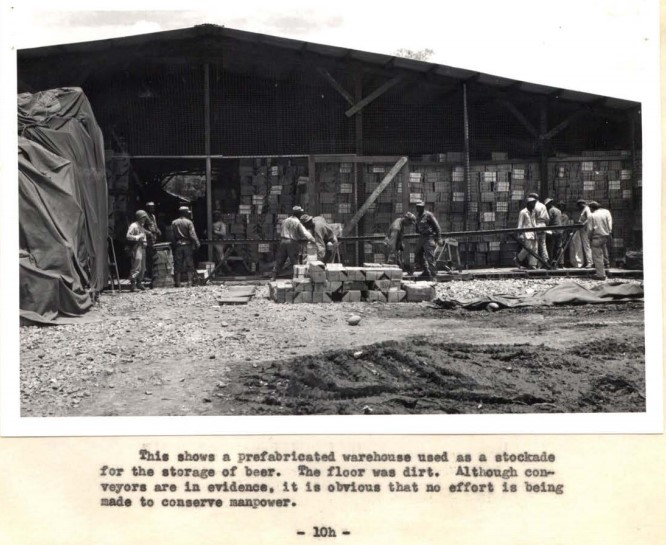

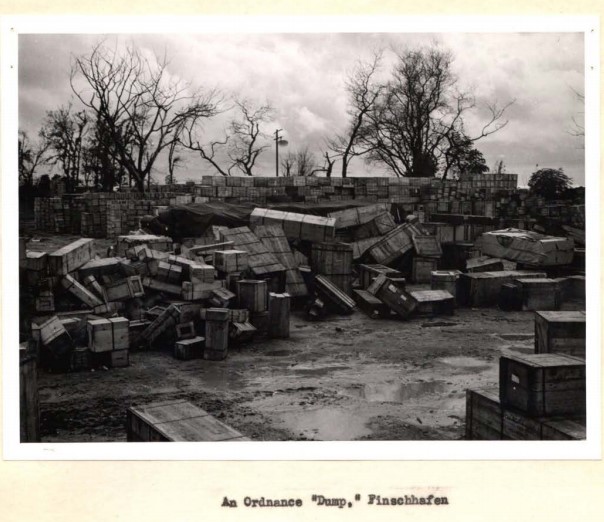

Imagine trying to inventory and mark for the proper consignee, & move a mess like this.

Which was actually a good day for the San Francisco POE.

5/

Which was actually a good day for the San Francisco POE.

5/

Per the NPS San Fran POE link:

"The port and its subsidiary, served by three transcontinental railroads, handled more than 350,000 freight car loads, and employed 30,000 military and civilian employees, not counting the longshoremen who loaded and unloaded cars and ships."

6/

"The port and its subsidiary, served by three transcontinental railroads, handled more than 350,000 freight car loads, and employed 30,000 military and civilian employees, not counting the longshoremen who loaded and unloaded cars and ships."

6/

Per this link:

"In 1939, the SFPE employed 831 military and civilian personnel. They shipped 48,000 tons of cargo that year. By the end of WW2, in 1945, the SFPE employed more than 30,000 people.

7/

hmdb.org/m.asp?m=70000

"In 1939, the SFPE employed 831 military and civilian personnel. They shipped 48,000 tons of cargo that year. By the end of WW2, in 1945, the SFPE employed more than 30,000 people.

7/

hmdb.org/m.asp?m=70000

...They shipped more than 23 million tons of cargo and 1.65 million soldiers on 4,000 freighters & 800 troopships."

Not mentioned in either link is that the War Dept. fired three San Fran POE directors during WW2.

8/

Not mentioned in either link is that the War Dept. fired three San Fran POE directors during WW2.

8/

The last firing happened shortly before the end of WW2, because something needed to be done to logistically support the planned Operation Downfall invasions of the Japanese home islands.

It was the illusion of "doing something."

9/

It was the illusion of "doing something."

9/

The "Great Pacific Supply Chain Collapse" going into Downfall was years in the making. And It was well mapped by a War Dept. investigator in Sept-Oct 1944.

See:

Col. Crosby's report on trip to Pacific Ocean Area and Southeast Pacific Area.

cgsc.contentdm.oclc.org/digital/collec…

10/

See:

Col. Crosby's report on trip to Pacific Ocean Area and Southeast Pacific Area.

cgsc.contentdm.oclc.org/digital/collec…

10/

Col. Crosby put in the miles and time to investigate everything involved the the Pacific War supply chain. Every major port operation in Adm. Nimitz's & General Macarthur's theater's were investigated & photographed.

11/

11/

In the time before ISO containers & container ships, good warehousing, rail & port operations for break bulk freighters required nets, pallets, roller conveyors, forklifts, cranes and military stevedores.

Who were disproportionately African-American in the Jim Crow era.

12/

Who were disproportionately African-American in the Jim Crow era.

12/

The problem that Crosby found in his travels was the lack of skills/supplies/infrastructure to effectively use pallets, roller conveyors, & forklifts.

Material handling equipment (MHE), then or now, required skilled manpower, spare parts & proper infrastructure to use.

13/

Material handling equipment (MHE), then or now, required skilled manpower, spare parts & proper infrastructure to use.

13/

In his visit to Oro Bay rear in MacArthur's theater, Crosby found that despite having fork lifts, pallets & leadership deeply committed to mechanization to save manpower. It simply wasn't happening.

14/

14/

The meeting tonnage metrics now beat efficient for the future.

Spoilage or theft of offloaded tonnage was not measured.

It was the "Department of Someone Else's Problem."

15/

Spoilage or theft of offloaded tonnage was not measured.

It was the "Department of Someone Else's Problem."

15/

Different bases didn't share overages of pallets forklifts with bases lacking them because there was no effective communications nor incentives to do so.

[The parallels with containers & their carriers in the ports of LA & Long Beach today stand out.]

16/

[The parallels with containers & their carriers in the ports of LA & Long Beach today stand out.]

16/

Then there was the real elephant in the pacific supply chain room...inter-service rivalry.

It wasn't simply a matter of the US Navy being in charge, not understanding Army needs & short changing them.

And there was a lot of that.

17/

It wasn't simply a matter of the US Navy being in charge, not understanding Army needs & short changing them.

And there was a lot of that.

17/

In fact, A whole lot of that. The USN considered all merchant hulls in it's theater it's property.

No matter if they were War Shipping Administration, War Dept. charter or Army Transport Service. When it came to shipping, the USN was:

"All you bases are belong to us"

18/

No matter if they were War Shipping Administration, War Dept. charter or Army Transport Service. When it came to shipping, the USN was:

"All you bases are belong to us"

18/

And it was more than the old saw of "The Navy gets the gravy while the Army get the beans."

Nope, it was the USN decided what was priority shipping for the theater including the building materials for Army infrastructure.

So the Army didn't get cement.

Literally, see:

19/

Nope, it was the USN decided what was priority shipping for the theater including the building materials for Army infrastructure.

So the Army didn't get cement.

Literally, see:

19/

Adm. Nimitz and his CENTPAC staff did more to stop US Army infrastructure building in the Pacific than all the torpedoes in the Japanese Navy!

And it went to actively sabotaging MacArthur's operations.

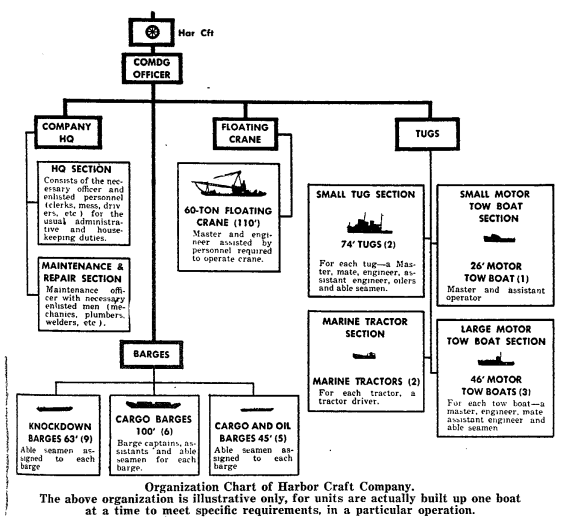

USN stole a complete harbor crft comp meant to land supplies at Leyte!

20/

And it went to actively sabotaging MacArthur's operations.

USN stole a complete harbor crft comp meant to land supplies at Leyte!

20/

A US Army harbor company w/o it's craft are over trained stevedores. Which was what the USN wanted to slow down MacArthur.

I found that bit of sabotage on pare 79 of the following document:

History of Army Port and Service Command.

cgsc.contentdm.oclc.org/digital/collec…

21/

I found that bit of sabotage on pare 79 of the following document:

History of Army Port and Service Command.

cgsc.contentdm.oclc.org/digital/collec…

21/

And made sure to confirm it was sabotage by looking up Eniwetok's tugs & lighterage in the following photo clipped document:

Base facilities summary: advance bases, Central Pacific Area, 30 June, 1945.

cgsc.contentdm.oclc.org/digital/collec…

22/

Base facilities summary: advance bases, Central Pacific Area, 30 June, 1945.

cgsc.contentdm.oclc.org/digital/collec…

22/

And then checking every tug, barge, floating crane and craft against this document:

Navy Seagoing Tugs and Related Craft

researcheratlarge.com/Ships/Misc/194…

23/

Navy Seagoing Tugs and Related Craft

researcheratlarge.com/Ships/Misc/194…

23/

Whatever happened to those Transportation Corps watercraft. They were not at Eniwetok in June 1945 despite a huge number of USN lighterage being inoperative.

Nor did they ever make it to Leyte.

24/

Nor did they ever make it to Leyte.

24/

While MacArthur's supply issues at Leyte are blamed on Kamikazes & his own disorganization -- the official narrative.

The USN's "Grand Theft Army Watercraft" at Eniwetok played a bigger role in stopping MacArthur's supplies at Leyte than the HMIJS Yamato lead central force

25/

The USN's "Grand Theft Army Watercraft" at Eniwetok played a bigger role in stopping MacArthur's supplies at Leyte than the HMIJS Yamato lead central force

25/

Yet it can be said that Col Crosby's fact finding tour bore fruit for the Pacific Supply Chain in the SWPA.

By Jan 1945 the SWPA shipping regulation system communicated about shipping & port capacity in every base & with the West coast.

cgsc.contentdm.oclc.org/digital/collec…

26/

By Jan 1945 the SWPA shipping regulation system communicated about shipping & port capacity in every base & with the West coast.

cgsc.contentdm.oclc.org/digital/collec…

26/

Yet for all the effort, the SWPA regulating system didn't fix the problem.

It only managed it.

27/

It only managed it.

27/

The heart of the issue was the dysfunction between the USN and the War Department, and especially the service troop impasse in the South Pacific.

The service troop needed for Downfall were Army & belonged to MacArthur, but the USN would not release operational control.

28/

The service troop needed for Downfall were Army & belonged to MacArthur, but the USN would not release operational control.

28/

The impasse leading to the "Great Pacific Supply Chain Collapse" during the planned invasion of Japan was broken not by agreement between supply chain stakeholders.

It was broken by the Atomic bombing of Hiroshima and Nagasaki.

29/

It was broken by the Atomic bombing of Hiroshima and Nagasaki.

29/

Just like it will take outside events to make the on-going the "Great World Supply Chain Collapse" irrelevant.

Pray G-d this supply chain collapse requires something much less drastic.

/End

Pray G-d this supply chain collapse requires something much less drastic.

/End

• • •

Missing some Tweet in this thread? You can try to

force a refresh