A friend working at the Indian R&D centre of one of the chip design behemoths of US spoke with regards to what we need to do. He sees little value in bringing TSMC large scale fabs in India. He says the marginal value add will only be few thousand skilled jobs at a huge cost! (+)

He told about a story where few Chinese chip design engineers from his company came out and started their own chip design effort with state support and ecosystem in China. Today apparently they own 30% of the market segment in China against this US behemoth. (+)

What clicked for the Chinese, he says was the existence of a semi fab ecosystem (not the TSMC types but the small scale types that can print to design for MSMEs) and a ready market of electronics makers who were ready to switch from Western behemoths. (+)

China’s chip market is apparently 50 times the size of India’s chip market. (There’s a difference being market for an end product and market for a chip assembly). For the latter to happen, India needs its own consumer and industrial electronics firms to come up. (+)

He says a single floor of engineers of his R&D centre in India if they come out and start their own, they can definitely develop chips for a wide range of low to mid level applications. But they can’t today because there’s lack of MSME and/or prototyping fabs & capital available

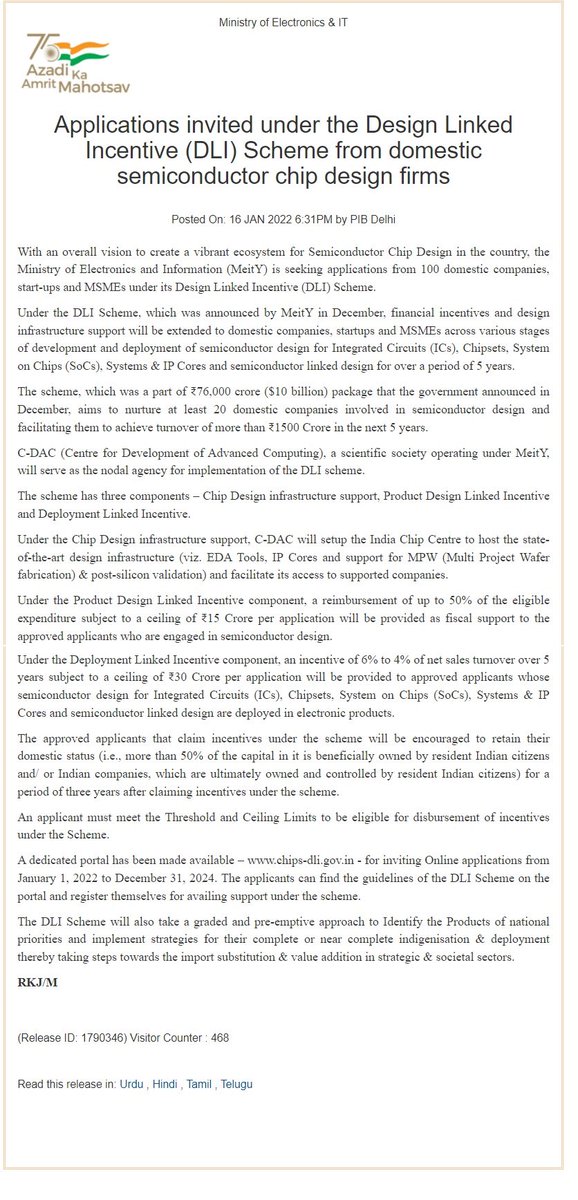

This apparently is the biggest difference. A TSMC or GF fab is going to mfg only for large scale Western behemoths. Chip IP stays with the West, mfg IP and value stays with TSMC with just employment generated. It is only when we start investing in domestic academic fabs to (+)

complement the Design Linked Incentives(DLI) that the Modi govt has announced will we be able to realize the final product of Indian designed and developed IP and become true owners of the tech and gain tech sovereignty in this domain. (+)

In this regard, we need Atleast few prototyping/academic fabs for different segments where both industrial development and producing and academic research can happen. That’s how you leap frog. That’s how you own the knowledge.

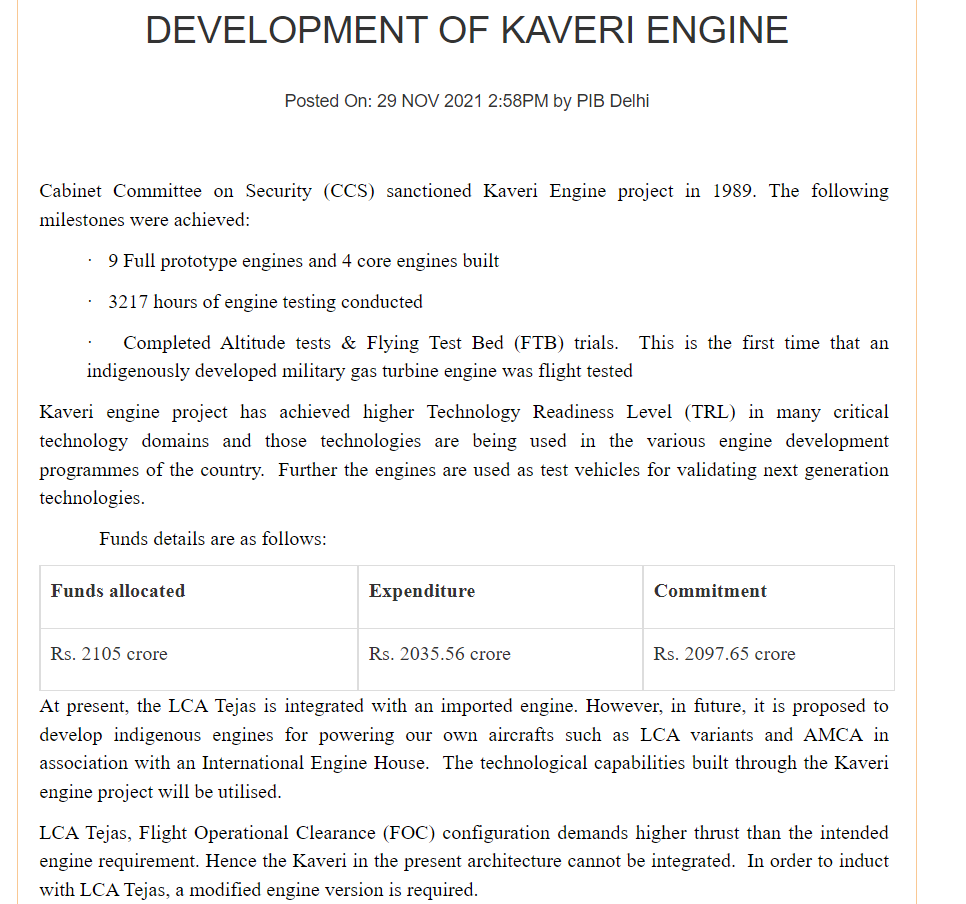

On that note, the govt’s Design Linked Incentives to support Chip design companies is truly welcome. Solves to some extent the capital part of the problem. business-standard.com/article/econom…

But the necessity of small scale prototyping fab is under appreciated. An investment of a $ 1 Billion will get us few academic fabs within the right academic research environment. We don’t know what happened to these proposals. indianexpress.com/article/educat…

We will have to leverage these kind of partnerships with Western semiconductor companies to gain base know-why and use that foster local startups and companies. thehindubusinessline.com/news/applied-m…

How TSMC typically operates. It seeks full ownership of its overseas plants.

https://twitter.com/nano_arun/status/1481998298861150211

The DLI scheme announced few days back. So we are half way through doing all the right things. But this is a puzzle where all pieces are necessary and the most crucial piece is a vibrant small scale mfg ecosystem in the semiconductor space for these companies to mfr their designs

A different and more informed perspective from a person who knows the industry much better.

https://twitter.com/nano_arun/status/1482970494827917316?s=20

And since some are inclined to deliberately mischaracterise my thread, here’s what I wrote when the Semiconductor PLI came in. Those who can’t understand “good enough but can do more” aspect.

https://twitter.com/cvkrishnan/status/1471142071998111746

• • •

Missing some Tweet in this thread? You can try to

force a refresh