1. Company Overview

• The company is in the business of developing and deploying technology led sustainable solutions that help conserve the environment. Praj has focused on the environment, energy, and agri-process industry.

• The company is in the business of developing and deploying technology led sustainable solutions that help conserve the environment. Praj has focused on the environment, energy, and agri-process industry.

• Praj’s diverse portfolio comprises Bio-energy solutions, High purity water systems, Breweries, Critical process equipment & skids and Zero liquid discharge systems.

• Company delivers value to customers with its unique TEMPO (Technology, Engineering, Manufacturing, Project management and Operations) model. In addition to its own technology development, Praj also builds strategic collaborations with global technology leaders

• The company has set up distilleries at multiple locations in India as well as other countries. Praj has 100% market share in colombia. It has also provided the technology requirement for largest ethanol capacity in U.K of Vivergo Fuels.

2. Management

• Praj was incorporated by technocrat promoter Dr. Pramod chaudhari. Dr. Chaudhari is an IIT Bombay graduate and an alumnus of Harvard business school.

• Praj was incorporated by technocrat promoter Dr. Pramod chaudhari. Dr. Chaudhari is an IIT Bombay graduate and an alumnus of Harvard business school.

Being a first generation entrepreneur, Dr Chaudhrai founded Praj industries with deep passion for bio-economy and environment sustainability, and developed praj into a specialised engineering company for agro-processing and bio-sustainability opportunities.

He is the first Indian to receive prestigious 2020 George Washington Carver Award

• Mr. Shishir Joshipura is a mechanical engineer from Birla institute of technology (BITS) Pilani and a management graduate from Harvard business school.

Mr Joshipura began his career with Thermax Ltd and progressed the way to become executive vice president and global head for heating & cooling business. He has over 35 years of experience in varied fields of engineering and served as managing director for SKF india ltd.

3. Business Overview

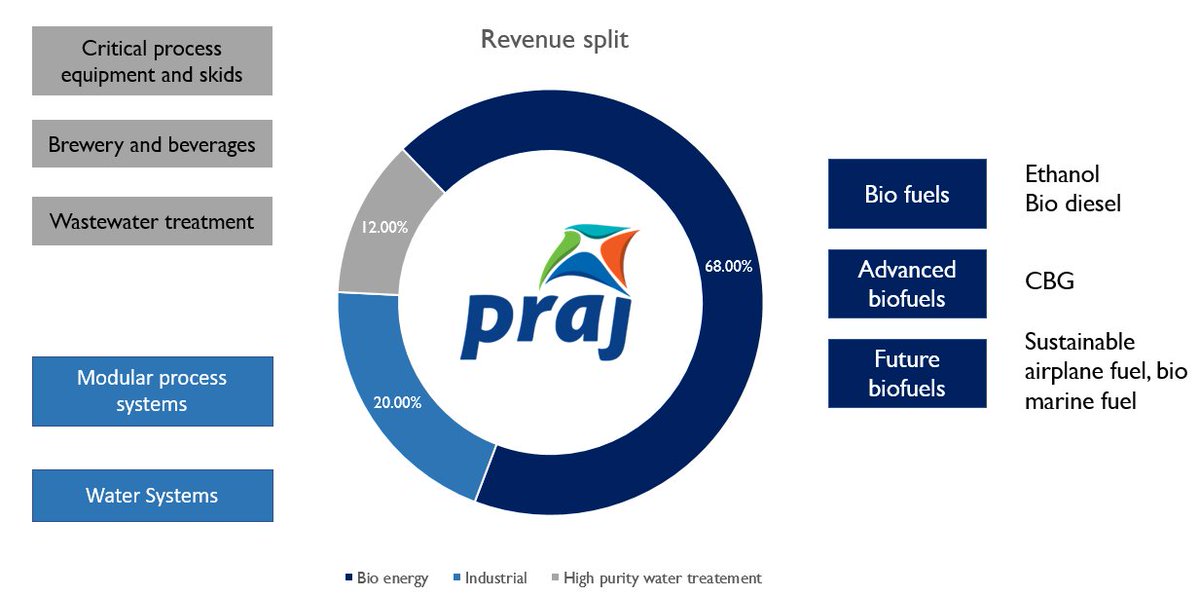

The company has three major business segments with highest contribution to revenues from Bioenergy segment i.e 68%, followed by Engineering business contributing 20% and High purity solutions business which is contributing the rest 12%.

The company has three major business segments with highest contribution to revenues from Bioenergy segment i.e 68%, followed by Engineering business contributing 20% and High purity solutions business which is contributing the rest 12%.

4. Bioenergy business segment

The bioenergy business is classified into providing technology solutions for

• Biofuels such as 1st generation ethanol plants and biodiesel plants.

• Advanced biofuels such as 2nd generation ethanol and compressed biogas(CBG)

The bioenergy business is classified into providing technology solutions for

• Biofuels such as 1st generation ethanol plants and biodiesel plants.

• Advanced biofuels such as 2nd generation ethanol and compressed biogas(CBG)

• Future biofuels such as sustainable aviation fuel(SAF), bio marine fuel, bio methanol and bio hydrogen.

Biofuels are produced using any of the three types of bio-based feedstock namely sugary (C molasses, B molasses, sugar syrup etc.), starchy (damaged/ surplus grains) and cellulosic (agri residues and biomass).

Praj envisages use of renewable biological resources to produce low carbon transportation fuels across all modes of mobility.

5. Ethanol Industry Outlook

• Ethanol is used as blends for fuel, industrial solvents and potable alcohol for breweries and distilleries. The US and Brazil are the largest manufacturers of ethanol with more than 80% market share.

• Ethanol is used as blends for fuel, industrial solvents and potable alcohol for breweries and distilleries. The US and Brazil are the largest manufacturers of ethanol with more than 80% market share.

The ethanol manufactured in these countries is used in blending of fuel to reduce the nations dependency on fossil fuels .Brazil has plans to be fossil fuel free country, thus increasing the use of ethanol.

• The domestic Bioenergy sector has seen significant momentum with several positive and structured measures announced to boost the ethanol consumption in India.

• Currently the annual ethanol production capacity in India is around 6.5 billion litres.

• Currently the annual ethanol production capacity in India is around 6.5 billion litres.

With advancing government policy on a 20% ethanol blending target by 5 years, an additional 10 billion litres per annum ethanol capacity will be required to fulfil the upcoming demand.

• Ethanol blending in India begun during the early 2000, but faced a few challenges

1. Movement of ethanol was difficult due to high state taxes. This was overcome by implementation of GST

2. Restrictions on using only C-molasses as feedstock stood a challenge

1. Movement of ethanol was difficult due to high state taxes. This was overcome by implementation of GST

2. Restrictions on using only C-molasses as feedstock stood a challenge

3. Lack of financial support to sugar companies from institutions due to stretched balance sheets was a challenge which was later overcome by interest subvention.

• The vehicle engines can easily sustain the 20% blended fuel. Higher technology engines will be required to accept the high petrol blends. The blending levels are currently at 10% and will be reaching 20% by 2030.

• In India, sugarcane is used as primary feedstock to manufacture ethanol. Before 2018, ethanol was procured from C molasses which is a result after sugar extraction from the cane juice.

In 2019, the government allowed the use of B molasses, cane juice and grains for producing ethanol resulting in a heavy capex cycle for ethanol companies.

• Relaxation on the restrictions of feedstock used for manufacturing ethanol and aggressive capital expansion for ethanol distilleries by Indian sugar companies will act as a key driver for the bioenergy business.

• Ethanol is derived from 1st generation and 2nd generation processes. Both the processes are similar and involve fermentation, however the feedstock is different.

In 1st generation plants, the feedstock used is sugarcane, corn or grains whereas lignocellulosic feedstock (agri waste, rice straws, wheat straws, bagasse) is used in 2nd generation plants

6. 1st Generation ethanol plants

• Several enabling factors such as interest subvention for projects, five year buying visibility, upward price revisions, quick environmental clearance etc. are introduced to attract investments in the sector.

• Several enabling factors such as interest subvention for projects, five year buying visibility, upward price revisions, quick environmental clearance etc. are introduced to attract investments in the sector.

• Currently the majority of the ethanol production in the country is dominated by three states namely Uttar Pradesh, Maharashtra, and Karnataka that produce ethanol using sugar based feedstock.

With the shift in policy other states are taking proactive steps to attract investments for ethanol plants based on starchy feedstock. As starchy feedstock is available across the nation, it will help build-up a robust ecosystem for nationwide production of ethanol.

Company is witnessing increasing enquiries for ethanol plants based on starchy feedstock.

• International outlook: With surge in demand for pharma grade alcohol to be used in sanitization, the company received a contract for our single largest pharma grade alcohol facility for a customer in the US and have bagged four more orders.

The company is building starchy feedstock based plants in Canada and Mexico for two leading producers.

7. 2nd Generation ethanol plants

Praj is developing three advanced biofuel refineries in India which are based on proprietary technology “enfinity” and the first project will be commissioned in June 2022.

Praj is developing three advanced biofuel refineries in India which are based on proprietary technology “enfinity” and the first project will be commissioned in June 2022.

• The company is working on solutions for process integration and operating cost reduction.

• Company has optimised and integrated Sekab’s CelluAPP technology for converting forest residue to ethanol in Praj Matrix.Association with Sekab for penetrating promising markets in northern Europe is progressing well.

• Europe announced to double their ethanol blending to 15% by 2025. The government has also mandated that only 2G plants will be set up for future capacities. There will be a penalty of 3euro/litre on future capacities if they are not 2nd generation plants.

• Both the plants give out the same products but the technological requirements are higher in 2nd generation plants resulting in higher cost of capex

• The key challenge in 2nd generation plants is procurement of feedstock, the plant location has to be selected accordingly with a procurement radius of 50km, only then the supply chain will run successfully.

8. Compressed Biogas (CBG)

• India currently imports 45% of natural gas which is further processed for producing compressed natural gas (CNG) that is extensively used in meeting India’s energy demand.

• India currently imports 45% of natural gas which is further processed for producing compressed natural gas (CNG) that is extensively used in meeting India’s energy demand.

• CBG (compressed biogas) is gaining popularity due to procurement from agri feedstock and also having 10% higher efficiency in engines compared to CNG.

CBG is a high octane renewable gaseous fuel produced by processing bio based feedstock such as press mud, agricultural residue.

• Post launch of the SATAT program that envisages setting up of 5000 CBG plants over a period of five years, efforts are underway to develop the ecosystem. The CBG plant requires a minimal capex of 50 Cr whereas a 2nd generation ethanol plant requires 1000 Cr of capex.

This translates to an opportunity size of approximately 2,50,000 Cr only in the CBG segment.

• Company has commissioned its CBG demo plant based on agriculture waste and other organic wastes at Praj Matrix. The plant deploys Praj’s ‘RenGas’ technology that utilises a proprietary microbial consortium for converting feedstock such as agri residues and press mud to CBG.

Company is also contracted to build a rice straw to CBG project in Uttar Pradesh. This project has a potential to save up to 15000 MT of CO2 emissions per year.

9. Bioproducts

The biosyrup technology developed by the company helps in increasing the shelf life of cane juice and enables year round ethanol production using syrup as feedstock.The yield in sugar companies is lower due to change in quality of sugarcane thus praj

The biosyrup technology developed by the company helps in increasing the shelf life of cane juice and enables year round ethanol production using syrup as feedstock.The yield in sugar companies is lower due to change in quality of sugarcane thus praj

has developed high technology enzymes to increase the shelf life of cane juice upto 1 year. This helps in increasing the yield and plant utilisation. It is a low volume high value product in the portfolio.

10. Future biofuels

• Company is developing the technology to convert the ethanol into high octane isobutanol.The company is in partnership with GEVO Inc, USA and developed a process for production of Isobutanol.

• Company is developing the technology to convert the ethanol into high octane isobutanol.The company is in partnership with GEVO Inc, USA and developed a process for production of Isobutanol.

The SAF samples have received certification as ‘fit for use’ in aircrafts from the Indian Air Force and the technology is now ready for commercialization.

• Ethanol can be used as a building block for bio chemicals

• Ethanol can be used as a building block for bio chemicals

• In ethanol expansion 30% of the capex is required for plant and machinery, 30% for water treatment and the rest 40% for safety, site development and other expenses.

• Most of the sugar companies have Praj industries technology, thus opportunity size for Praj industries is huge as the company expects nearly 12000-14000 Cr for equipment orders in coming years.

12. Engineering business

The engineering business is classified into providing solution such as

The engineering business is classified into providing solution such as

• Critical process equipment and skids (CPES)

It offers pressure vessels, reactors, shell & tube heat exchangers, columns, and other proprietary equipment as per the client design requirements which are used in sectors such as Oil & Gas,

It offers pressure vessels, reactors, shell & tube heat exchangers, columns, and other proprietary equipment as per the client design requirements which are used in sectors such as Oil & Gas,

Refineries, Petrochemicals, and Fertiliser, among many others.

Last year, CPES received multiple contracts from a US-headquartered Industrial Gases company for supply of Critical Equipment and Modules used for production of Hydrogen.

Last year, CPES received multiple contracts from a US-headquartered Industrial Gases company for supply of Critical Equipment and Modules used for production of Hydrogen.

• Brewery and Beverages

Praj has proven expertise ranging from engineering and designing to construction of plants and process equipment. Praj has 75% market share in setting up brewery plants in india.

Praj has proven expertise ranging from engineering and designing to construction of plants and process equipment. Praj has 75% market share in setting up brewery plants in india.

The technology for distillery and oil companies is similar therefore Praj is manufacturing critical process equipment for oil companies. The pandemic situation has adversely impacted the domestic beer market.

On account of a fall in consumption of end products attributable to pandemic, it is currently experiencing a slowdown in new investments.

The company is building India’s largest apple juice concentrate plant in Himachal pradesh. Few orders were bagged from Niger and Kenya on the international front.

• Zero Liquid Discharge Solutions (ZLD)

The company offers comprehensive range of solutions for industrial effluent treatment, recycling and zero liquid discharge (ZLD) systems to customers across several sectors.

The company offers comprehensive range of solutions for industrial effluent treatment, recycling and zero liquid discharge (ZLD) systems to customers across several sectors.

In FY 20-21, the company bagged several repeat orders from customers and made a major breakthrough in the refinery & petrochemical segment with a large order for water and wastewater treatment system including Zero Liquid Discharge for their Acrylic/Oxo-Alcohol Project.

13. High Purity Systems

Praj HiPurity Systems (PHS) is a wholly-owned subsidiary of Praj Industries Limited which offers ultra-high purity water systems (WS), modular process systems (MPS) and fermentation solutions to customers engaged in biopharmaceuticals, sterile formulations

Praj HiPurity Systems (PHS) is a wholly-owned subsidiary of Praj Industries Limited which offers ultra-high purity water systems (WS), modular process systems (MPS) and fermentation solutions to customers engaged in biopharmaceuticals, sterile formulations

complex injectable, personal care and nutraceutical offerings.

14. Innovation and R&D

• The company has entered into a MoU with Automotive Research Association of India (ARAI) to jointly drive application development of advanced biofuels.

14. Innovation and R&D

• The company has entered into a MoU with Automotive Research Association of India (ARAI) to jointly drive application development of advanced biofuels.

• Developing different molecules and biopolymers that are sustainable alternatives to products made from fossil resources which are having growth potential in industries such as Bio-plastics, Cellulose –Lignin refinery products, Specialty chemicals,

Agri-supplements and Bio-industrial products.

• Praj has also joined hands with Institute of Chemical Technology, Mumbai (ICT) for developing innovative solutions for the process industry.

• Praj has also joined hands with Institute of Chemical Technology, Mumbai (ICT) for developing innovative solutions for the process industry.

• Recently it has achieved another breakthrough for producing “Bio-bitumen” based on lignin, an eco-friendly renewable material for road construction, Lignin is one of the co-products resulting from the 2G ethanol plants, paper making and also from CBG plants.

• Till date, the Company has been granted 24 Indian patents and 60 international patents and has filed over 300 international patents till date

15. Oder book

• The Order book for praj looks healthy with increasing number of orders in pipeline for bio-energy segment

• 80% of the orderbook is from domestic industry

• The Order book for praj looks healthy with increasing number of orders in pipeline for bio-energy segment

• 80% of the orderbook is from domestic industry

A new wave is now ushering in the industrial revolution viz. Industry 5.0 Version 2. Bioeconomy is envisaged as integral part of industry 5.0 acceding due importance to sustainability in all business endeavours the emphasis is going to be on deeper

penetration of green energy in the overall energy basket and adoption of green products & materials

• • •

Missing some Tweet in this thread? You can try to

force a refresh