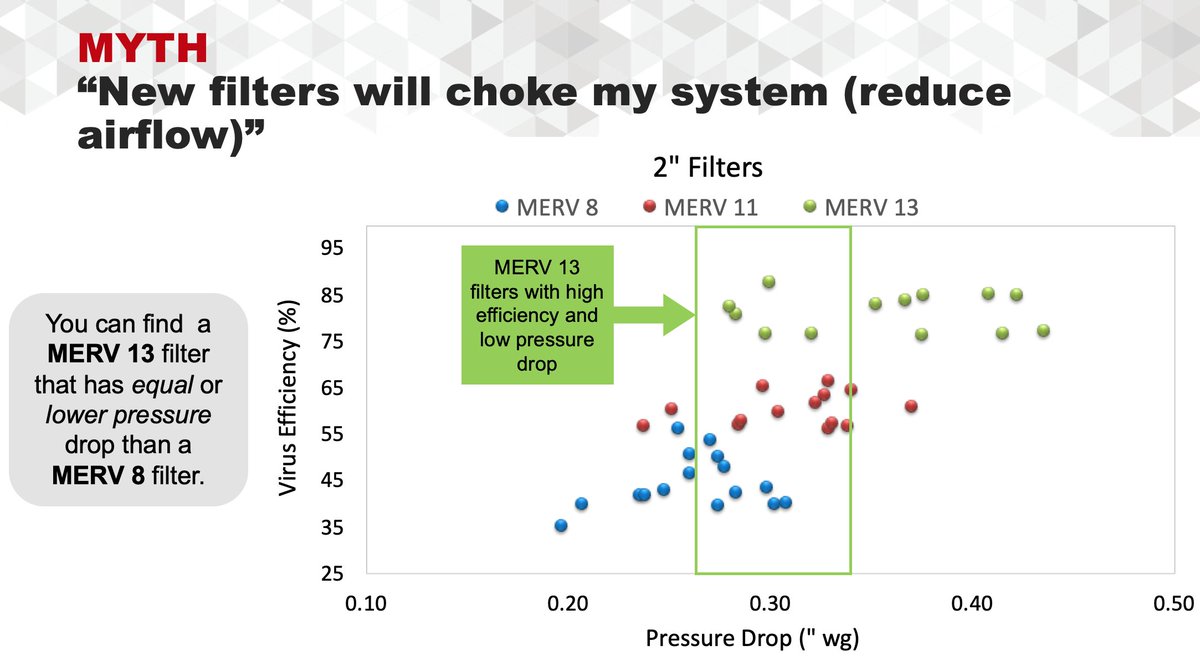

1) About MERV 13 - upgrading filters to MERV13 is the cheapest and most consistent/ practical solution:

For a 10,000 ft2 school buildings or 15 classrooms, it only costs $546/YEAR. This simple upgrade will give you ~5 ACH.

For a 10,000 ft2 school buildings or 15 classrooms, it only costs $546/YEAR. This simple upgrade will give you ~5 ACH.

https://twitter.com/j_g_allen/status/1361279469588271110

2) About air purifiers, it costs equal or more than $250 to put 1 purifier in 1 classroom (500 ft2) to give ~5 ACH.

Here is a collection of air purifiers available on the market (fan + HEPA filter) compared by cost/ft2 and noise.

Here is a collection of air purifiers available on the market (fan + HEPA filter) compared by cost/ft2 and noise.

3) About ventilation (1/3): if the building open the outside air dampers as designed (per minimum code), you get an extra 4.23 ACH.

-> A lot of studies found that schools are under ventilated because the operators chose to save energy (closing the outside damper on purpose)

-> A lot of studies found that schools are under ventilated because the operators chose to save energy (closing the outside damper on purpose)

(2/3) Starting March, many schools can benefit from economizer mode ( free cooling), meaning that they can open the outside air damper without any taxation on the system.

if units are old or not operational then this will not be feasible.

if units are old or not operational then this will not be feasible.

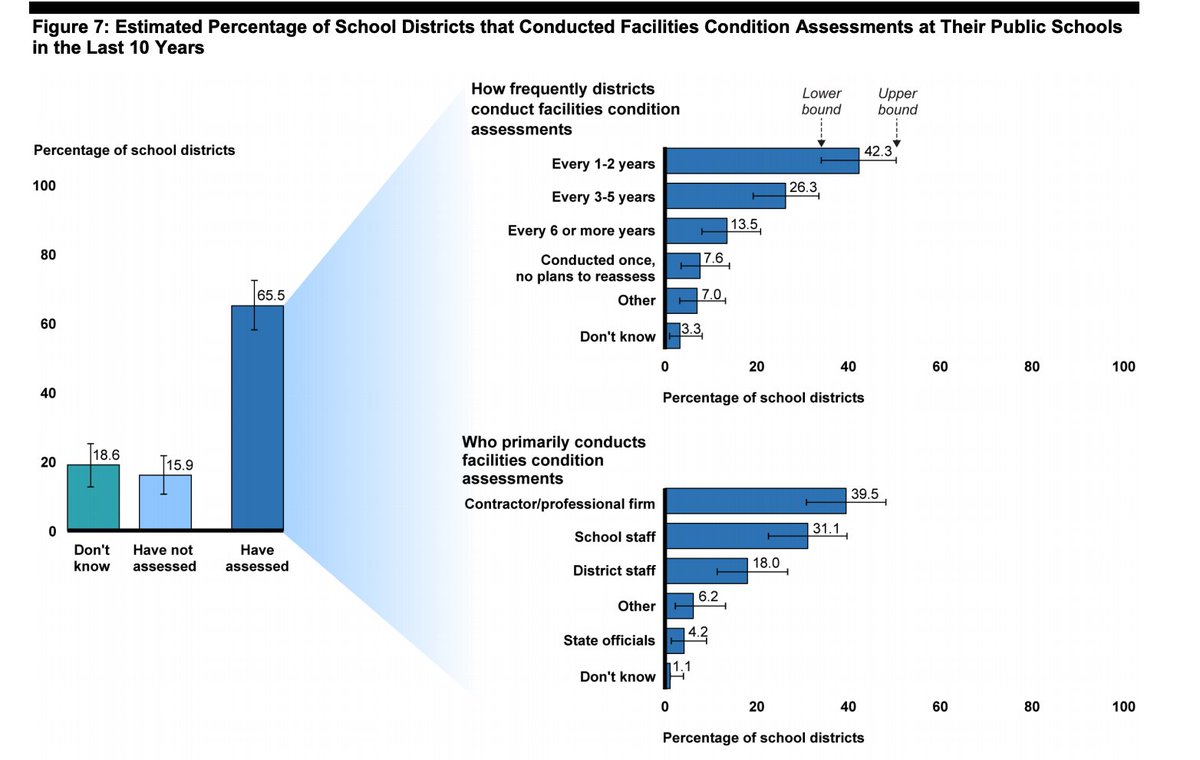

(3) Many schools do facility assessments. These assessments are key to understanding whether the HVAC system can handle outside air.

We need to be asking for those assessments to make data-driven decision.

We need to be asking for those assessments to make data-driven decision.

• • •

Missing some Tweet in this thread? You can try to

force a refresh