Last week @BloombergNEF published its first outlook for Solid-state adoption, featured in the @climate article bloom.bg/2Pal36L.

Here is a quick thread on some of the key points:

1/6 #battchat

Here is a quick thread on some of the key points:

1/6 #battchat

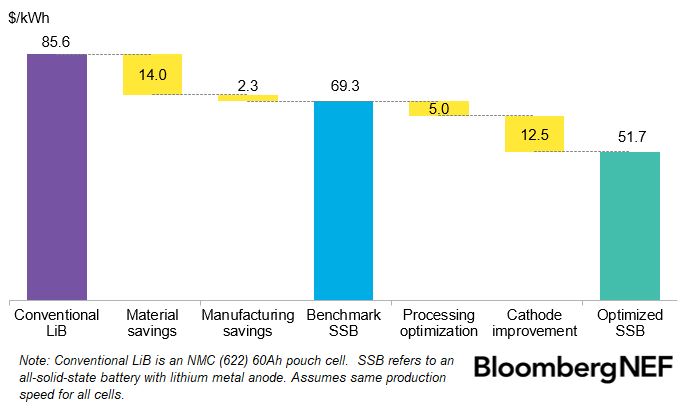

1. We expect solid-state cells to be adopted in premium EVs first because they will be higher cost than liquid based cells.

2. We expect they could be cheaper by 2033, after this point adoption in non-premium segments accelerates.

2. We expect they could be cheaper by 2033, after this point adoption in non-premium segments accelerates.

3.We modeled EV economics, assuming the increase in range for a given pack size (kWh) would be favored. But if auto's use smaller packs to achieve the same range as liquid based cells, EVs using solid-state cells could be affordable sooner. It will probably be a mix in reality.

4. Part of our cost analysis focused on the time taken for the supply chain to scale. If this happens faster, particularly because of developments in China, then solid-state cells could be cheaper sooner.

5. We only focused on the US and Europe here because China is taking a different route. Using solid electrolytes as separators in liquid cells first, and then slowly substituting components until they have full solid state...

...European and US companies are aiming to launch products that are full solid-state (@SolidPowerInc, @Ilikaplc), or only contain a small amount of catholyte (@QuantumScapeCo) and with next-gen anodes from the get go.

fin

fin

• • •

Missing some Tweet in this thread? You can try to

force a refresh