1. Introduction

As the name goes Clean Science,The company focuses on innovation, and creating clean green innovative chemical processes using catalytic chemistry.

Incorporated in 2003, Clean Science and Technology Ltd is one of the leading manufacturers of functionally

As the name goes Clean Science,The company focuses on innovation, and creating clean green innovative chemical processes using catalytic chemistry.

Incorporated in 2003, Clean Science and Technology Ltd is one of the leading manufacturers of functionally

critical specialty chemicals such as Performance chemicals, Pharmaceutical intermediates and FMCG Chemicals.

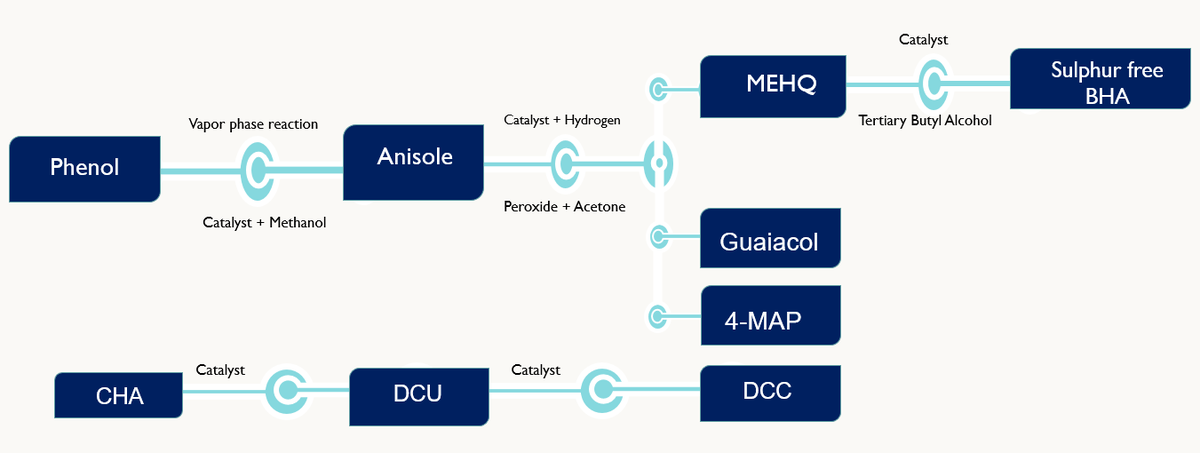

Only chemical enterprise in the world which has been successful in commercialising hydroxylation of Anisole through vapour phase technology.

Only chemical enterprise in the world which has been successful in commercialising hydroxylation of Anisole through vapour phase technology.

Clean science competes with Camlin fine science and Yasho industries in the Food antioxidants and performance chemical business.

3. Business Segments

The company’s business is diversified into three broad classification of Performance chemicals, Pharmaceutical Chemicals and FMCG chemicals having application in agrochemical, food antioxidants, animal feed industry, cosmetic industry and F&F companies.

The company’s business is diversified into three broad classification of Performance chemicals, Pharmaceutical Chemicals and FMCG chemicals having application in agrochemical, food antioxidants, animal feed industry, cosmetic industry and F&F companies.

Performance Chemicals

Performance chemicals are products used to enhance the product life and performance of the final goods. Used across industries of industries like Pharmaceuticals, Petrochemicals, Agrochemicals, and Dyes & Pigments industries, among others.

Performance chemicals are products used to enhance the product life and performance of the final goods. Used across industries of industries like Pharmaceuticals, Petrochemicals, Agrochemicals, and Dyes & Pigments industries, among others.

The products manufactured are:

MEHQ- Mono methyl ether of hydroquinone is an organic compound and synthetic derivative of hydroquinone. MEHQ has applications in super absorbent polymers (diapers and sanitary pads), Cosmetics & Agrochemicals

MEHQ- Mono methyl ether of hydroquinone is an organic compound and synthetic derivative of hydroquinone. MEHQ has applications in super absorbent polymers (diapers and sanitary pads), Cosmetics & Agrochemicals

BHA- Butylated Hydroxyanisole or BHA is a white crystalline powder or a yellowish-white waxy solid used as an antioxidant in the food industry, animal feed ,nutrition and cosmetic industry.

AP- Ascorbyl Palmitate, a fat soluble form of ascorbic acid, recognised universally as a safe ingredient for use in infant, food, cosmetics, and many other application

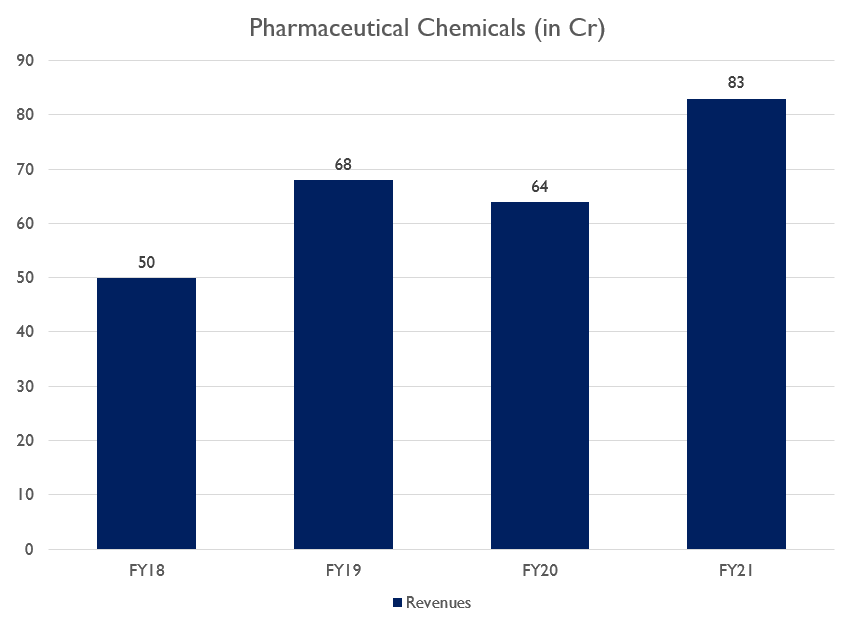

Pharmaceutical Chemicals

The products manufactured have application in the pharmaceutical API industries.

The products manufactured have application in the pharmaceutical API industries.

Guaiacol and DCC are two products in the segment. Guaiacol is a naturally-occurring organic compound used as a precursor to manufacture API for cough syrup and is also a key raw material DCC is used as an anti-retroviral.

FMCG Chemicals

Traditionally food additives were extracted from natural resources. Chemical synthesis have cost effective applications and production.

Traditionally food additives were extracted from natural resources. Chemical synthesis have cost effective applications and production.

4-MAP and Anisole are FMCG chemicals manufactured by the company. 4-MAP has application in sunscreen products where it is used as UV blocker and anisole is used in F&F industry as a precursor to perfumes, insect pheromones and pharmaceuticals

4.Process Innovation

Conventionally, MEHQ, BHA, TBHQ etc were made from hydroquinone. Phenol was forward integrated to hydroquinone and catechol was generated as a byproduct. CSTL developed the technology to manufacture the above products from Anisole. This technology was present

Conventionally, MEHQ, BHA, TBHQ etc were made from hydroquinone. Phenol was forward integrated to hydroquinone and catechol was generated as a byproduct. CSTL developed the technology to manufacture the above products from Anisole. This technology was present

earlier, however clean science developed the proprietary technology to manufacture anisole from phenol. CSTL uses vapour phase technology to convert phenol to anisole helping them achieve the lowest manufacturing cost.

This breakthrough resulted in lower price of production against the competitors and thus resulting in higher margins. The company is fully backward integrated and uses phenol as KSM to manufacture forward integrated products.

5. Industry Outlook

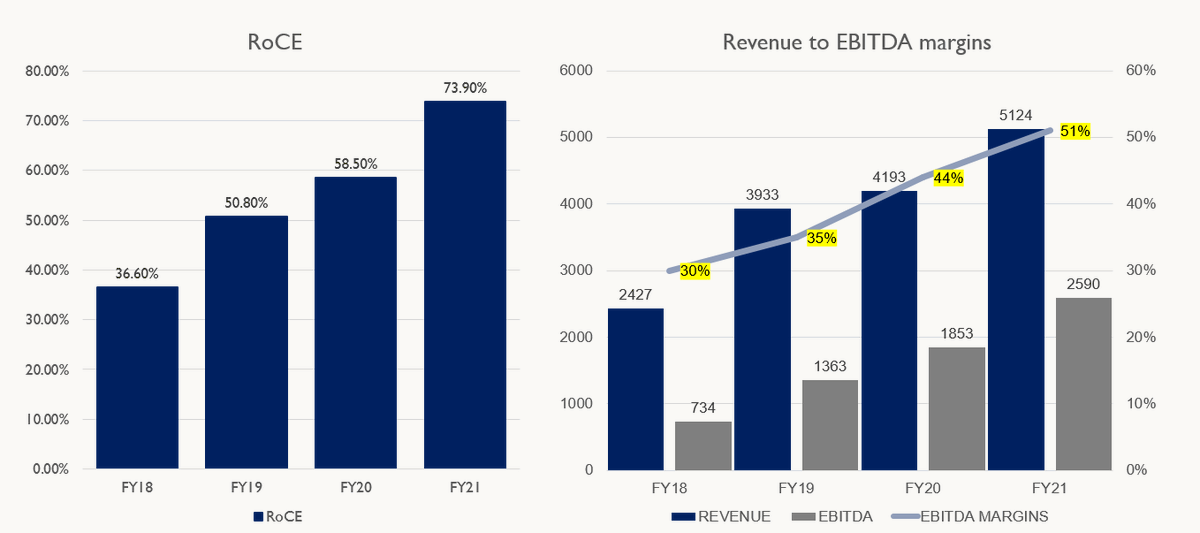

CSTL is the market leader for most of the products. The operating margins of CSTL are above 50% which is higher than most of the peers in industry.

CSTL is the market leader for most of the products. The operating margins of CSTL are above 50% which is higher than most of the peers in industry.

During high raw material price cycle, CSTL is able to absorb the incremental cost and sells for lesser price compared to its competitors, thus giving them the competitive advantage

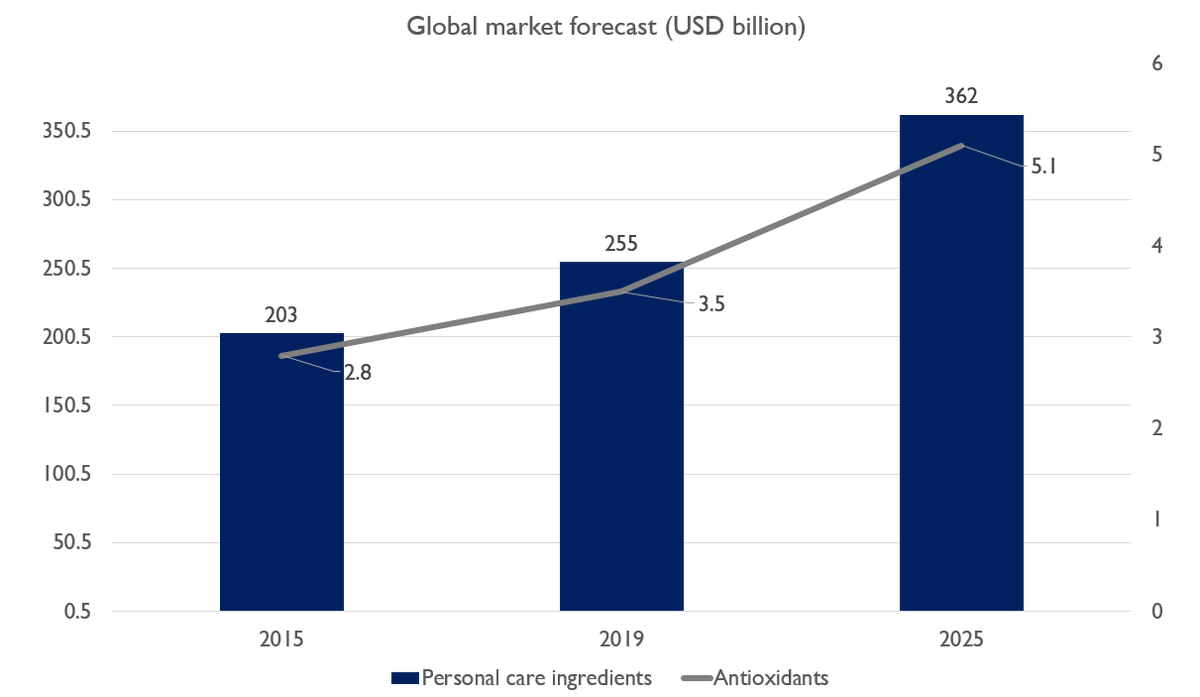

Most of the products are used in the antioxidant, and cosmetic industry. Antioxidants market is expected to grow at 6.3% from 2019-2025

CTSL has dominant market share in most of the products. It is the largest manufacturer of MEHQ and BHA in India and globally.

Over the years, the company has been increasing its wallet share among customers and existing customers are asking for new products to complete the product basket.

Export Revenues

75% of revenues is driven from export markets thus the company has customers in different parts of the world. America is the largest export market followed by China for CSTL.

75% of revenues is driven from export markets thus the company has customers in different parts of the world. America is the largest export market followed by China for CSTL.

7. Manufacturing facilities

Three manufacturing facilities located at Kurkumbh (Maharashtra) with 11 production lines which had a combined installed capacity of 29,900 MTPA

Unit 1 has 7 MPP plants and unit 2 has 4 MPP plants

Three manufacturing facilities located at Kurkumbh (Maharashtra) with 11 production lines which had a combined installed capacity of 29,900 MTPA

Unit 1 has 7 MPP plants and unit 2 has 4 MPP plants

8. Capacity Expansion

CSTL has commissioned two new plants in Unit 3 for manufacturing PBQ and TBHQ in Q3FY22.

Have also increased the capacity of product BHA by about 50 odd percent.

More new plants are going to come up by September or October 2022, that are the HALS series.

CSTL has commissioned two new plants in Unit 3 for manufacturing PBQ and TBHQ in Q3FY22.

Have also increased the capacity of product BHA by about 50 odd percent.

More new plants are going to come up by September or October 2022, that are the HALS series.

9. Product launches

HALS- HALS manufactured from amine based chemical compounds, and can be used as efficient stabilisers for polymers and plastics.These compounds are used primarily to safeguard polymers against the photo-oxidation effects

HALS- HALS manufactured from amine based chemical compounds, and can be used as efficient stabilisers for polymers and plastics.These compounds are used primarily to safeguard polymers against the photo-oxidation effects

PBQ- Para benzoquinone was typically made by Chinese companies, and CSTL is the only company in India to start production of PBQ. PBQ finds application in the agro and monomer industry.

TBHQ- Tert-butylhydroquinone is used as a stabiliser in edible oil. The most important reason to start this product is all customers who buy BHA and Ascorbyl Palmitate from CSTL need TBHQ to complete the basket and hence this will increase the wallet share with the customer.

• • •

Missing some Tweet in this thread? You can try to

force a refresh