#Paushak - Monopoly in #phosgene ? 🧪🧪

Detailed Thread 🧵🧵

Like & Retweet for better reach !

Cmp - ₹ 12097

Detailed Thread 🧵🧵

Like & Retweet for better reach !

Cmp - ₹ 12097

1. Introduction

Paushak Limited is an India-based phosgene specialty chemicals company.

The Company is engaged in the production of phosgene gas and phosgene-based specialty chemicals/ intermediates.

Paushak is part of the Alembic group of companies situated in Gujarat, India.

Paushak Limited is an India-based phosgene specialty chemicals company.

The Company is engaged in the production of phosgene gas and phosgene-based specialty chemicals/ intermediates.

Paushak is part of the Alembic group of companies situated in Gujarat, India.

Alembic Ltd is one of the oldest pharmaceutical companies in India .

The products have applications in pharmaceuticals, agrochemicals and performance chemicals industry.

The products have applications in pharmaceuticals, agrochemicals and performance chemicals industry.

2. Business Segments

The company manufactures phosgene derivatives which are classified into 4 categories of Isocyanates , Chloroformates, Carbamates and Carbamoyl Chlorides.

Phosgene is a colourless, odourless poisonous gas at room temperature, it needs to be cooled so that

The company manufactures phosgene derivatives which are classified into 4 categories of Isocyanates , Chloroformates, Carbamates and Carbamoyl Chlorides.

Phosgene is a colourless, odourless poisonous gas at room temperature, it needs to be cooled so that

it turns liquid and can be transported easily. Phosgene was used as a chemical weapon during world war 1, where it was responsible for 85,000 deaths.

The chemistry of phosgene is quite simplified where only chlorine and carbon monoxide in presence of light is needed to make

The chemistry of phosgene is quite simplified where only chlorine and carbon monoxide in presence of light is needed to make

phosgene, however the high toxicity makes the chemistry difficult to handle.

3. End Industry

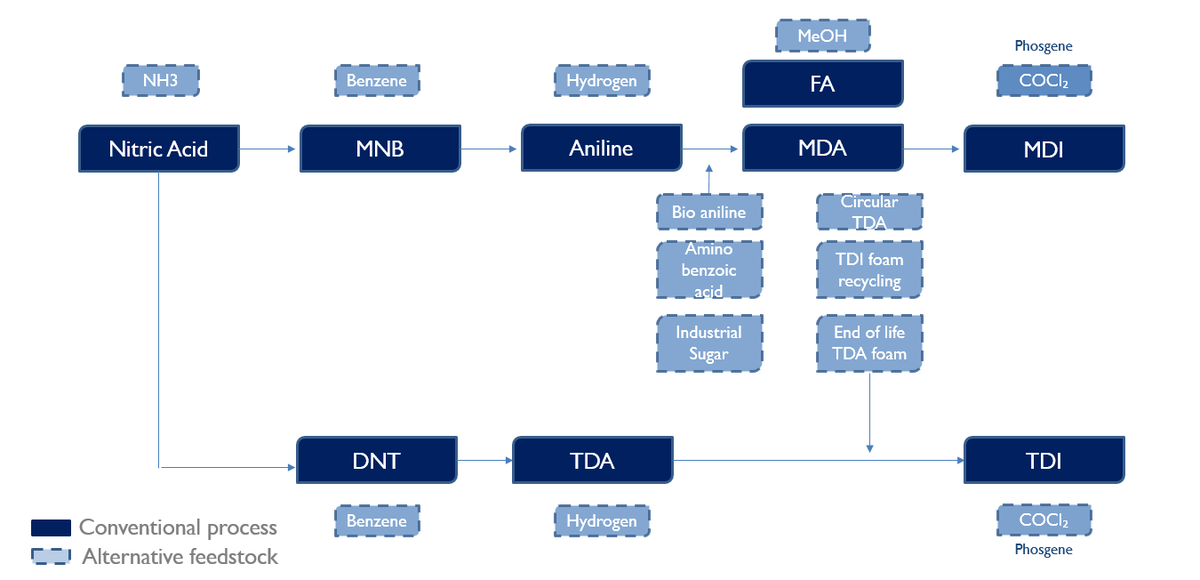

1. Isocyanates: It is derived from synthesis of phosgene with amines and is majorly used in manufacturing of polyurethane and polycarbonate products.

3. End Industry

1. Isocyanates: It is derived from synthesis of phosgene with amines and is majorly used in manufacturing of polyurethane and polycarbonate products.

Polyurethane and polycarbonates are widely used in manufacturing foam mattresses. MDI (Methylene diphenyl diisocyanate) and TDI ( Toluene diisocyanate) are widely used in the Isocyanate family,

however the company has forward integrated the value chain to manufacture high value products

2. Chloroformates

Phosgene reacted with alcoholic functional group results in chloroformate products. Chloroformates have a wide range of applications as reagents in organic chemistry due to their nature of high reactivity. The intermediates are used in the manufacture

Phosgene reacted with alcoholic functional group results in chloroformate products. Chloroformates have a wide range of applications as reagents in organic chemistry due to their nature of high reactivity. The intermediates are used in the manufacture

of organic peroxide initiators for use in plastics and in activating groups used to make antibiotics and other pharmaceuticals. Some molecules also find application in the agrochemical industry where they are used in pesticides and insecticides.

3. Carbamates: It is derived from synthesis of phosgene with diols. Carbamate derivatives are widely represented in agricultural chemicals, such as pesticides, fungicides, and herbicides. Some products are forward integrated from the existing basket.

4. History of Paushak

In 1981, Pasuhak started the commercial manufacturing of phosgene with 1400 MT capacity. The company expanded the capacity for the first time after 33 years to 4800 MT translating to 3X increase in capacities.

In 1981, Pasuhak started the commercial manufacturing of phosgene with 1400 MT capacity. The company expanded the capacity for the first time after 33 years to 4800 MT translating to 3X increase in capacities.

However during 2014 to 2019 the capacity expansion was proposed to increase the capacity by 5X from 4800 MT to 14,400 MT.

5. Capacity Expansion

The company manufactures only phosgene and its derivatives with an existing capacity of 4800 MT.

Paushak is under a capex program of 120 Cr where the capacity of phosgene is increasing from 4800 to 14400 MT and adding a new segment of

The company manufactures only phosgene and its derivatives with an existing capacity of 4800 MT.

Paushak is under a capex program of 120 Cr where the capacity of phosgene is increasing from 4800 to 14400 MT and adding a new segment of

pharmaceutical API’s with 29 products and 190 MT capacity.

6. High Toxicity

The phosgene is a highly toxic gas and can result in extreme accidents if not handled properly.

The bhopal gas tragedy in 1984 was a result of toxic gas leak of methyl isocynate.

6. High Toxicity

The phosgene is a highly toxic gas and can result in extreme accidents if not handled properly.

The bhopal gas tragedy in 1984 was a result of toxic gas leak of methyl isocynate.

It was manufactured by Union Carbide which was used in agrochemical industry

7. Less dependence on China

The raw material required by Pasuahk is simply chlorine gas and carbon monoxide. Abundance of raw materials has reduced the dependency on China

Shutdown of chinese

7. Less dependence on China

The raw material required by Pasuahk is simply chlorine gas and carbon monoxide. Abundance of raw materials has reduced the dependency on China

Shutdown of chinese

chemical companies due to stricter environment norms are driving the demand.

The labour cost (hourly cost of compensation) in China was lower than that of India till 2007. However, over 2005-2015, the average labour cost in China

The labour cost (hourly cost of compensation) in China was lower than that of India till 2007. However, over 2005-2015, the average labour cost in China

increased nearly 19-20%,against 4-5% CAGR in India. In fact, over the last five years, this cost has more than doubled compared with India

10. Polyurethanes market

The polyurethane market has one of the largest applications of phosgene and MDI and TDI are two major derivatives of phosgene used in this industry.

The polyurethane market has one of the largest applications of phosgene and MDI and TDI are two major derivatives of phosgene used in this industry.

MDI and TDI are used by foam making industries which are used in mattress, construction, cushions, automobiles, footwear etc and other foam products.

11. Top manufacturers of MDI and TDI

Covestro and BASF are the leading manufacturers of TDI and MDI with the highest global market share. The companies have some of the largest capacities for phosgene and

Covestro and BASF are the leading manufacturers of TDI and MDI with the highest global market share. The companies have some of the largest capacities for phosgene and

use it captively for manufacturing products which have application in polyurethane and other industries

12. MDI production in India

GNFC manufactures TDI for and is one of the largest manufacturers in India, however the company is not backward integrated to manufacture phosgene.

GNFC chemical business revenue in FY2021 contributed 64% to topline translate to value of 3305 Cr.

GNFC manufactures TDI for and is one of the largest manufacturers in India, however the company is not backward integrated to manufacture phosgene.

GNFC chemical business revenue in FY2021 contributed 64% to topline translate to value of 3305 Cr.

TDI contributed 27% of chemical revenues translating to 892Cr.

13. Phosgene use in agrochemicals

Derivatives of phosgene such as isocyanates, carbamates and chloroformates have a wide range of application in crop protection and technicals used in the agrochemical industry.

13. Phosgene use in agrochemicals

Derivatives of phosgene such as isocyanates, carbamates and chloroformates have a wide range of application in crop protection and technicals used in the agrochemical industry.

The toxicity of phosgene makes it suitable for use in insecticides, herbicides and pesticides.

Some companies using phosgene derivatives as raw materials

Some companies using phosgene derivatives as raw materials

• • •

Missing some Tweet in this thread? You can try to

force a refresh