iPod touch prototypes

On the right: Fifth generation iPod touch, PROTO1 stage

On the left: Sixth generation iPod touch, DVT stage

On the right: Fifth generation iPod touch, PROTO1 stage

On the left: Sixth generation iPod touch, DVT stage

The fifth generation unit features laser marks on the device and a double line of holes for the speaker.

This unit was the first iPod touch to feature the lightning connector as well. Previous stages of the same unit feature legacy 30 pin dock connector.

This unit was the first iPod touch to feature the lightning connector as well. Previous stages of the same unit feature legacy 30 pin dock connector.

The sixth generation unit features holes on the chassis to allow easy access to RF interfaces on the main board and battery logic board. It was likely used by FCC as part of the model compliance validation process.

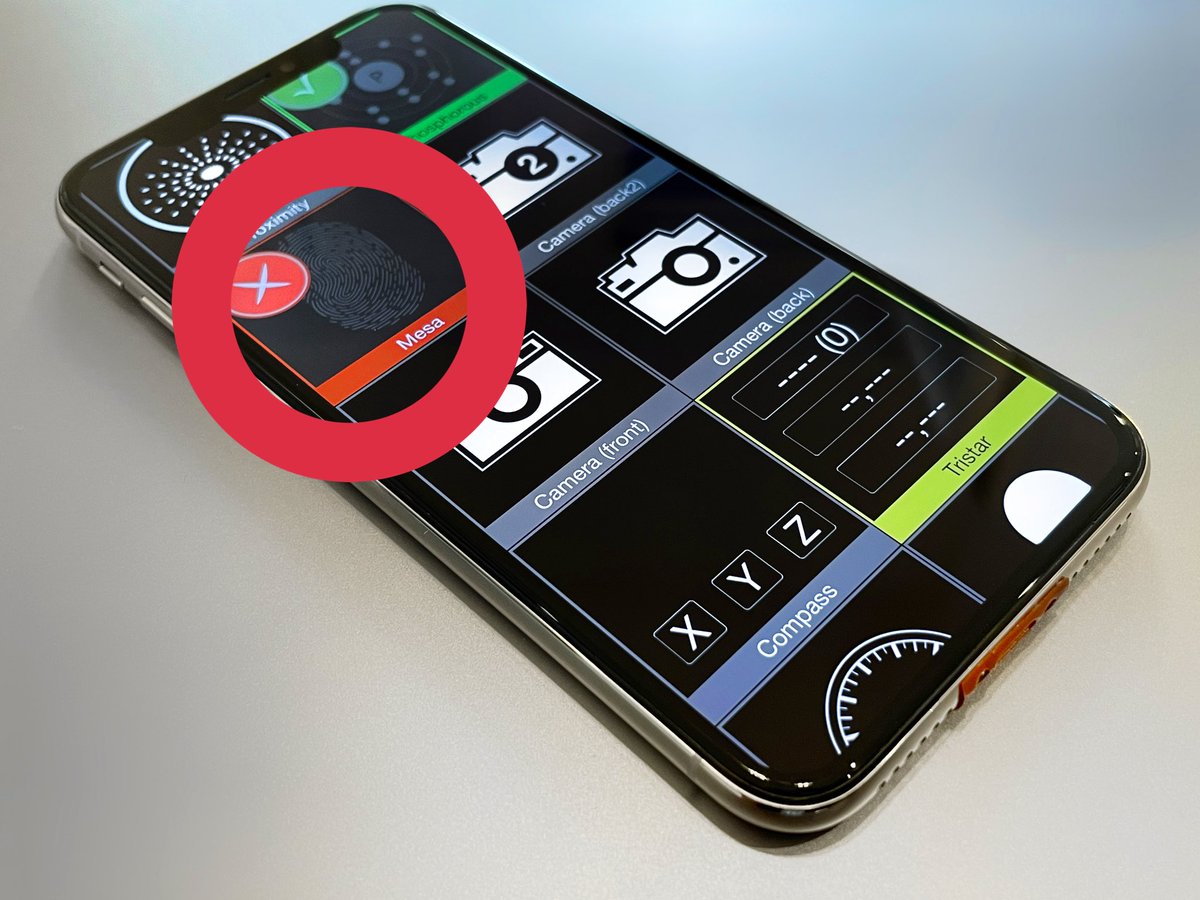

Both units run a nonUI version of iOS, used in factories to run tests on development units, named SwitchBoard:

They run their release base version, 6.0 for the 5th generation and 8.3 for the 6th generation.

They run their release base version, 6.0 for the 5th generation and 8.3 for the 6th generation.

It’s quite curious how Apple introduced a new boot logo for development devices, getting rid of the skeuomorphic gear in favor of a flat gear icon, almost in the same period as the normal iOS migration, with iOS 7.

• • •

Missing some Tweet in this thread? You can try to

force a refresh