#Nuclear #Thorium #LFTR

#China #钍 #TMSR

New 203 page PDF! (2020 Dec 29)

minqin.gov.cn/Upload/main/Co… (5.5 MB)

via minqin.gov.cn/zw/tzgg/conten…

"Operation Phase Environmental Impact Assessment"

@gordonmcdowell

@FissionLiquide

@StephenABoydPh1

@OskaArcher

@AchalHP

#China #钍 #TMSR

New 203 page PDF! (2020 Dec 29)

minqin.gov.cn/Upload/main/Co… (5.5 MB)

via minqin.gov.cn/zw/tzgg/conten…

"Operation Phase Environmental Impact Assessment"

@gordonmcdowell

@FissionLiquide

@StephenABoydPh1

@OskaArcher

@AchalHP

上海应物所承担中国科学院战略性先导科技专项“未来先进核裂变能——钍基熔盐堆核能系统(TMSR)”,研究和发展相关核能科学与技术,打造TMSR全产业链,目标是成为拥有最先进、最完备实验设施和条件,以工业应用为目标的世界级钍基熔盐堆核能系统的研究中心。

"Shanghai Inst. of Sci. and Tech. undertakes the strategic leading technology project of the Chinese Acad. of Sciences, "Future Advanced Nuclear Fission Energy-Thorium-based Molten Salt Reactor Nuclear Energy System (TMSR)", to research & develop related nuclear energy science &

technology, and build the entire TMSR industrial chain. The goal is to become a world-class thorium-based molten salt reactor nuclear energy system research center with the most advanced & complete experimental facilities and conditions, with the goal of industrial application."

近期,钍基熔盐堆核能系统(TMSR)研发被列入《能源技术革命创新行动计划(2016-2030)》(发改能源[2016]513号 )。

"the [R&D] of the thorium-based molten salt reactor nuclear energy system (TMSR) was included in the "Energy Technology Revolution & Innovation Action Plan (2016-2030)"

"the [R&D] of the thorium-based molten salt reactor nuclear energy system (TMSR) was included in the "Energy Technology Revolution & Innovation Action Plan (2016-2030)"

1.1.2 建设性质和资金来源本项目属于国家重大科技基础建设项目,为新建项目。本项目属于科学研究项目,资金来源于国家各类财政支持。本项目总投资暂定7.7145亿元,其中环保投资4860万元,占比6.3%。

"This... is a major national scientific and technological infrastructure construction project"

"This... is a major national scientific and technological infrastructure construction project"

"The total investment of this project is tentatively scheduled to be 77145 million yuan"

Google says that's ~$118 M (US)

Google says that's ~$118 M (US)

本项目近期建设项目主要有2MWt液态燃料钍基熔盐实验堆(TMSR-LF1)及其相关的配套设施(见表1.2-1),规划建设10MWt固态燃料熔盐实验堆(TMSR-SF1)

"The recent construction projects... mainly include the 2MWt liquid fuel thorium-based molten salt experimental reactor (TMSR-LF1)

"The recent construction projects... mainly include the 2MWt liquid fuel thorium-based molten salt experimental reactor (TMSR-LF1)

and related supporting facilities... and the planned construction of 10MWt solid fuel molten salt experimental reactor (TMSR-SF1)"

Oh! It seems they're still going to build the SF1🤔

Oh! It seems they're still going to build the SF1🤔

本项目于2019年10月开展并完成了实验堆主体装置厂房及放射性废物处理中心基坑负挖, 主体装置厂房自2020年3月底开展底板混凝土浇筑,计划于2021年2月启动堆容器吊装、2021年4月完成所有设备安装、2021年7月开展首次装料。

"This project was carried out in October 2019 and completed the negative excavation of the main plant of the experimental reactor and the foundation pit of the radioactive waste treatment center.

The main plant... started the bottom plate concrete pouring at the end of March 2020.

It is planned to start the hoisting of the stack container in Feb 2021.

All equipment installation will be completed in April 2021

the first material loading will be carried out in July 2021.

It is planned to start the hoisting of the stack container in Feb 2021.

All equipment installation will be completed in April 2021

the first material loading will be carried out in July 2021.

1.3 建设目的能源和资源的稳定供应是保障我国长期可持续发展的必要基础,核能是一种能量密度高、洁净、低碳的能源,是保障国家能源安全、促进节能减排的重要手段。我国的能源供应以化石能源为主,正面临着越来越严峻的能源需求持续增长和CO2减排的双重压力,核能占能源比重远低于工业化国家,

可以预计,未来几十年我国核能将大规模发展。作为第四代反应堆的候选堆型之一,熔盐堆因为具有高固有安全性、核废料少、物理防止核扩散和更好的经济性等特点成为热点之一。除具备四代堆的优点外,熔盐堆可以使用我国丰富的钍作为核燃料,降低对于铀的对外依存度。

因其以熔盐为冷却剂,还具有常压工作、无水冷却特性,可建于地下和干旱地区。熔盐堆输出温度为700度以上,可用于高温制氢、二氧化碳加氢制甲醇等高温热利用领域,对减少温室气体排放有重要意义。此外,熔盐堆适合于发展小型模块化堆技术,具有扩展核能多领域、多环境应用的极大潜力。

1.3 Construction purpose The stable supply of energy and resources is the necessary foundation to guarantee the long-term sustainable development of our country. Nuclear energy is a high-energy-density, clean, and low-carbon energy source.

It is an important means to ensure national energy security and promote energy conservation and emission reduction. my country’s energy supply is dominated by fossil energy, and it is facing the dual pressure of increasingly severe energy demand growth and CO2 emission reduction.

The proportion of nuclear energy in energy is much lower than that of industrialized countries. It can be predicted that my country’s nuclear energy will grow in the coming decades. Large-scale development. As one of the candidate reactor types for the fourth-generation reactor,

molten salt reactors have become one of the hot spots because of their high inherent safety, less nuclear waste, physical prevention of nuclear proliferation, and better economy. In addition to having the advantages of fourth-generation reactors,

molten salt reactors can use my country's abundant thorium as nuclear fuel, reducing the degree of dependence on uranium. Because it uses molten salt as the coolant, it also has the characteristics of normal pressure work and no water cooling,

and can be built in underground and arid areas. The output temperature of the molten salt reactor is over 700 degrees, which can be used in high-temperature heat utilization fields such as high-temperature hydrogen production and carbon dioxide hydrogenation to methanol, and is

of great significance to reducing greenhouse gas emissions. In addition, molten salt reactors are suitable for the development of small modular reactor technology and have great potential for expanding nuclear energy applications in multiple fields and multiple environments."

Interesting line:

鉴于其适合我国“富钍贫铀”的国情

"In view of its suitability for my country’s national conditions of “rich thorium and depleted uranium” "

鉴于其适合我国“富钍贫铀”的国情

"In view of its suitability for my country’s national conditions of “rich thorium and depleted uranium” "

我国首个液态燃料钍基熔盐堆将实现钍基熔盐堆的系统集成和验证,为模块化示范堆及大型商业堆的建设提供必要的技术、数据以及经验。同时通过实验堆及相关设施的建设,带动一大批涉及材料及高端装备制造技术的发展。

"my country's first liquid fuel thorium-based molten salt reactor will realize the system integration and verification... and provide necessary technology, data and experience for the construction of modular demonstration reactors and large-scale commercial reactors.

At the same time, the construction of experimental reactors and related facilities has promoted the development of a large number of materials and high-end equipment manufacturing technologies."

对于TMSR-LF1的稀有事故和极限事故,其个人剂量限值分别确定为:在每发生一次稀有事故时,场址边界上公众个人(成人)在整个事故持续时间内可能受到的有效剂量应控制在5 mSv以下;在每发生一次极限事故时,场址边界上公众个人(成人)在整个事故持续时间内可能受到的有效剂量应小于10 mSv

"For... TMSR-LF1, the individual dose limits are respectively determined as: in each rare accident, the effective dose that the public individual (adult) on the site boundary may receive during the entire accident duration should be controlled Below 5 mSv;

in each extreme accident, the effective dose that the public (adults) on the site boundary may receive during the entire duration of the accident should be less than 10 mSv"

考虑到TMSR-LF1为II类研究堆,热功率只有2MW,具有较高的固有安全性,包括:具有良好的负反馈特性;具有非能动余热排出系统;系统工作在近常压下;燃料盐能够限制放射性物质的释放;具有在线气体净化功能;具有防止放射性物质释放的多道屏障。

"Considering that TMSR-LF1 is a Type II research reactor with a thermal power of only 2MW, it has high inherent safety, including: good negative feedback characteristics; passive waste heat removal system; system working at near normal pressure;

fuel salt It can limit the release of radioactive materials; has the function of online gas purification; has multiple barriers to prevent the release of radioactive materials."

且本项目周围10km范围内无常住居民,

"there are no permanent residents within 10km around the project"

"there are no permanent residents within 10km around the project"

Section 1.5.3 is the "non-radioactive environmental impact assessment", and specifies (in part 2) "hydrogen fluoride (HF) as the main [potential chemical] pollutant"

2020年4月起,红砂岗气象站的总辐射和净辐射开始启动测量。

"From April 2020, Hongshagang Meteorological Station began to measure the total radiation and net radiation."

(thus establishing a background baseline)

"From April 2020, Hongshagang Meteorological Station began to measure the total radiation and net radiation."

(thus establishing a background baseline)

Table 1.5-1 mentions five types of "emissions of [radioactive] airborne effluent of this project" (with values; is this max for the permit?)

They are: noble gases, iodine, "Particles (half-life ≥8d)", C-14, and tritium.

They are: noble gases, iodine, "Particles (half-life ≥8d)", C-14, and tritium.

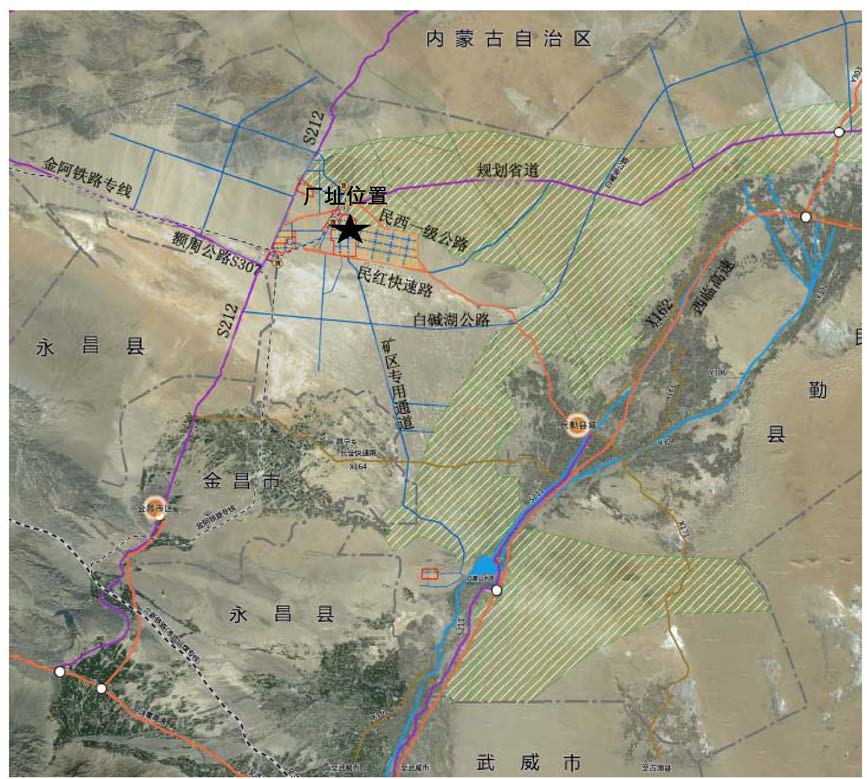

2.1.2.1厂址边界厂址位于园区西北部,南侧紧邻纬七路、东侧紧邻东环路。规划用地范围东西向长约694m,南北向长度约961m,总用地面积约为66.67hm2。[...] 厂址边界见图2.1-3。

"The site is located in the northwest of the park, adjacent to Weiqi Road on the south side and Donghuan Road on the east side. The planned land area is about 694m in east-west direction and 961m in north-south direction. The total land area is about 66.67hm2.

2MWt液态燃料钍基熔盐实验堆厂址半径50km范围内涉及甘肃省武威市(包括民勤县的红砂岗镇、昌宁镇、大坝镇、薛百镇)、金昌市(包括双湾镇)以及内蒙古阿拉善右旗。厂址半径10km范围内涉及甘肃省武威市的民勤县的红砂岗镇。

The 2MWt liquid fuel thorium-based molten salt experimental reactor site is within a 50km radius of Wuwei City, Gansu Province (including Hongshagang Town, Changning Town, Daba Town, and Xuebai Town in Minqin County), Jinchang City (including Shuangwan Town) )

And Alxa Right Banner in Inner Mongolia. Within a 10km radius of the site, it involves Hongshagang Town, Minqin County, Wuwei City, Gansu Province."

2.2.1 评价区人口分布厂址半径50km范围内截止到2015年底的常住总人口数为三万九千余人,

"2.2.1 Population distribution in the assessment area The total permanent population within a radius of 50km from the site as of the end of 2015 is more than 39,000."

"2.2.1 Population distribution in the assessment area The total permanent population within a radius of 50km from the site as of the end of 2015 is more than 39,000."

距厂址最近及最大的万人以上城镇为位于厂址SSW、SW 方位约53km 处的金昌市金川区城区,2015年底有人口十五余万人。其次为位于厂址SE方位约54km 处的武威市民勤县,2015 年底有人口六万九千余人

"The nearest and largest town with more than 10,000 people from the site is the urban area of Jinchuan District, Jinchang City, located about 53km away from the site of SSW and SW, with a population of more than 150,000 at the end of 2015.

The second is Minqin County, Wuwei, located about 54km away from SE of the factory site, with a population of over 69,000 at the end of 2015"

厂址半径10km内工业企业共有19家,经营产品主要为煤炭、化工产品、电力供应等,

"There are 19 industrial enterprises within a 10km radius of the factory site, and their products are mainly coal, chemical products, power supply, etc."

"There are 19 industrial enterprises within a 10km radius of the factory site, and their products are mainly coal, chemical products, power supply, etc."

厂址半径5km范围内无矿产资源,厂址不存在压覆矿现象。厂址半径10km范围内矿产资源分布中,矿产资源分布区上层有油页岩矿产,下层有煤炭分布。厂址半径10km范围内有两个矿区:

"There are no mineral resources within a radius of 5km from the site, and there is no overburden ore phenomenon

"There are no mineral resources within a radius of 5km from the site, and there is no overburden ore phenomenon

on the site. In the distribution of mineral resources within a 10km radius of the site, there are oil shale minerals in the upper layer of the mineral resource distribution area and coal in the lower layer. There are two mining areas within a 10km radius of the site"

厂址附近现有的危险品储存设施不会影响厂址安全,

"The [relatively small] existing dangerous goods storage facilities near the site will not affect the site’s safety"

"The [relatively small] existing dangerous goods storage facilities near the site will not affect the site’s safety"

文化设施厂址半径10km范围内无监狱、学校、医院和养老院。厂址半径10km范围内无省级以上文物保护单位、风景名胜区。厂址半径10km范围涉及1处国家级自然保护区,即甘肃民勤连古城国家级自然保护区,主要保护对象为荒漠天然植被群落、珍稀濒危野生动植物、古人类文化遗址和极端脆弱的荒漠生态系统。

"There are no prisons, schools, hospitals and nursing homes within a radius of 10km from the site of cultural facilities. There are no cultural relics protection units or scenic spots above the provincial level within a radius of 10km from the site.

The 10km radius of the site involves a national nature reserve, namely the Liangucheng National Nature Reserve in Minqin, Gansu.

The main protection objects are desert natural vegetation communities, rare and endangered wild animals and plants, ancient human cultural sites and extremely fragile desert ecology system."

2.3.2居民点和农牧场厂址半径10km范围内没有居民点。厂址半径10km范围内无菜田、农田、奶牛场、养殖场。

"There are no residential areas within a radius of 10km from the [plant] site. [Nor are there] vegetable field, farmland, dairy farm, or breeding farm within a radius of 10km"

"There are no residential areas within a radius of 10km from the [plant] site. [Nor are there] vegetable field, farmland, dairy farm, or breeding farm within a radius of 10km"

This really gets into the nitty gritty of siting a reactor, identifying all sorts of potential activities that could be affected: greenhouses, a characteristic forest and fruit industry, livestock and poultry farms (cattle, sheep, pigs, chickens), farmer co-op orgs, family farms

2.3.3.2陆生资源概况厂址周边区域地貌类型主要为戈壁滩(砾漠),无森林、草场分布。

"Overview of terrestrial resources The landform types around the plant site are mainly Gobi desert (gravel desert), with no forest or grassland distribution."

"Overview of terrestrial resources The landform types around the plant site are mainly Gobi desert (gravel desert), with no forest or grassland distribution."

厂址所在民勤县地处三面环沙,隔离条件好、环境污染少、病虫危害轻、光照充足、日较差大,

"Minqin County where the plant is located is surrounded by sand on 3 sides, w/ good isolation conditions, low enviro. pollution, light pests +diseases, sufficient sunlight, +large daily range."

"Minqin County where the plant is located is surrounded by sand on 3 sides, w/ good isolation conditions, low enviro. pollution, light pests +diseases, sufficient sunlight, +large daily range."

暖棚养殖为主的设施农牧业和以酿造葡萄、红枣、枸杞为主的特色林果业,

'animal husbandry, +agriculture based on greenhouses, with a characteristic forestry and fruit industry based on wine grapes, red dates, and medlars'

en.wikipedia.org/wiki/Mespilus_… ?

'animal husbandry, +agriculture based on greenhouses, with a characteristic forestry and fruit industry based on wine grapes, red dates, and medlars'

en.wikipedia.org/wiki/Mespilus_… ?

已稳定形成了以番茄、西甜瓜、人参果、辣椒、小乳瓜、沙葱等为主的温室瓜菜产业,

'greenhouse tomatoes, melons, ginseng fruits, peppers, small milk melons, and green onions'

'greenhouse tomatoes, melons, ginseng fruits, peppers, small milk melons, and green onions'

以及以甜瓜、辣椒、食葵、籽用葫芦、茴香等为主的大田高效节水种植业等特色优势产业。

'low water field plants like peppers, sunflower, seed gourds, and fennel.

'low water field plants like peppers, sunflower, seed gourds, and fennel.

BTW, not sure if 枸 in this context is "medlar"

https://twitter.com/ConradKnauer/status/1345213223671222273or en.wikipedia.org/wiki/Goji (the latter seems more likely)... not a tangent I was expecting to go on, but learning is an adventure ;)

2.3.4水产资源及生态概况厂址半径10km范围内无地表水系分布,因此不存在水产资源及水生态。

"Overview of aquatic resources and ecology There is no surface water system within a radius of 10km from the site, so there is no aquatic resources and aquatic ecology."

"Overview of aquatic resources and ecology There is no surface water system within a radius of 10km from the site, so there is no aquatic resources and aquatic ecology."

东、西、 北三面被腾格里沙漠和巴丹吉林沙漠包围,

"It is surrounded by the Tengger Desert +the Badain Jaran Desert on the east, west +north sides"

灾害天气主要有干旱、冰雹、暴雨、沙尘暴、霜冻等。

"Disaster weather mainly includes drought, hail, rainstorm, sandstorm, frost, etc."

"It is surrounded by the Tengger Desert +the Badain Jaran Desert on the east, west +north sides"

灾害天气主要有干旱、冰雹、暴雨、沙尘暴、霜冻等。

"Disaster weather mainly includes drought, hail, rainstorm, sandstorm, frost, etc."

年最小相对湿度为1%。

"The annual minimum relative humidity is 1%."

月平均降水量最大出现在8月份,为30.1mm,

"The maximum monthly average precipitation occurs in August, which is 30.1mm."

一日最大蒸发量为30.0mm。

"The maximum evaporation in one day is 30.0mm."

"The annual minimum relative humidity is 1%."

月平均降水量最大出现在8月份,为30.1mm,

"The maximum monthly average precipitation occurs in August, which is 30.1mm."

一日最大蒸发量为30.0mm。

"The maximum evaporation in one day is 30.0mm."

确定厂址区域百年一遇极端最高气温为44.2°C, 百年一遇极端最低气温为-34.1°C。

"It is determined that the extreme maximum temperature in the site area is 44.2°C in a century, and the extreme minimum temperature in the area is -34.1°C."

cf. Saskatchewan @gordonmcdowell ;)

"It is determined that the extreme maximum temperature in the site area is 44.2°C in a century, and the extreme minimum temperature in the area is -34.1°C."

cf. Saskatchewan @gordonmcdowell ;)

沙尘暴厂址区域累年平均沙尘暴日数在8~25d之间,民勤各月都有沙尘暴发生的可能性,

"The annual average number of sandstorm days in the site area is between 8 and 25 days. Minqin has the possibility of sandstorms every month."

"The annual average number of sandstorm days in the site area is between 8 and 25 days. Minqin has the possibility of sandstorms every month."

厂址区地下水埋深大于建筑物基础埋深,且新近系砾质砂岩厚度大且渗透系数较小,因此工程运行不会对地下水造成影响。

"The buried depth of groundwater in the plant site area is greater than that of the building foundation, and the Neogene gravel sandstone has a large thickness

"The buried depth of groundwater in the plant site area is greater than that of the building foundation, and the Neogene gravel sandstone has a large thickness

and a small permeability coefficient, so the project operation will not affect the groundwater."

厂址区地貌类型主要为戈壁滩(砾漠)。

"The landform type of the plant site area is mainly Gobi desert (gravel desert)."

厂址区地貌类型主要为戈壁滩(砾漠)。

"The landform type of the plant site area is mainly Gobi desert (gravel desert)."

厂址区及其邻近地区是一个构造活动相对稳定的地区,没有区域性活动断裂延伸到厂址附近范围。

"The plant site area and its adjacent area is a relatively stable area of tectonic activity, and no regional active faults extend to the vicinity of the plant site."

"The plant site area and its adjacent area is a relatively stable area of tectonic activity, and no regional active faults extend to the vicinity of the plant site."

"Figure 3.1-1 Layout of environmental gamma radiation dose rate monitoring points in the plant area"

Starting on PDF page 83:

第四章 2MWt液态燃料钍基熔盐实验堆

"Chapter 4 2MWt Liquid Fuel Thorium-based Molten Salt Experimental Reactor "

第四章 2MWt液态燃料钍基熔盐实验堆

"Chapter 4 2MWt Liquid Fuel Thorium-based Molten Salt Experimental Reactor "

近期拟建设2MWt液态燃料钍基熔盐实验堆(TMSR-LF1)及其相关的配套设施,主要包括主体装置厂房(LF1)、放射性废物处理中心(02)、综合实验大厅(03)、学术活动中心(04)、试剂仓库(05)、消防水泵房(06)、园区综合服务中心(07)、净水站(10)、

中水生产站(11)以及室外工程(包括控制区出入口、保护区出入口、保卫控制中心等)。

"In the near future, it is planned to build a 2MWt liquid fuel thorium-based molten salt experimental reactor (TMSR-LF1) and related supporting facilities, including the main plant (LF1),

"In the near future, it is planned to build a 2MWt liquid fuel thorium-based molten salt experimental reactor (TMSR-LF1) and related supporting facilities, including the main plant (LF1),

the radioactive waste treatment center (02), the comprehensive experimental hall (03), and academic activities Center (04), reagent warehouse (05), fire water pump room (06), park comprehensive service center (07), water purification station (10),

reclaimed water production station (11) and outdoor engineering (including control area entrances and exits, protection Zone entrances and exits, security control center, etc.)."

根据厂区总体规划,结合工程建设需求,将厂区分为北部装置区(包括西侧研究堆装置区、中间实验堆装置区、东侧放化区)、中部科研区(包括西侧能源综合利用区、东侧核能技术区)和南部生活区三大功能分区。

"According to the overall plan of the plant area and the needs of engineering construction, the plant is divided into the northern device area (including the western research reactor device area, the intermediate experimental reactor device area,

and the eastern radiochemical area), and the central scientific research area (including the west energy comprehensive utilization area) , Nuclear Energy Technology Zone on the east side) and three functional zones in the southern living area."

厂区设立三个出入口,主要出入口位于厂区南侧,与纬七路相连;次要出入口分别位于厂区东侧和西侧,与东环路、经七路相连。

"There are three entrances and exits in the factory. The main entrance is located on the south side of the factory and connected to Weiqi Road; the secondary entrances are located on the east and west sides of the factory and are connected to Donghuan Road and Jingqi Road."

4.1.2.1项目组成及规模本项目主要由主体装置厂房(LF1)、放射性废物处理中心(02)以及室外工程(包括控制区出入口、保护区出入口、保卫控制中心等)组成。

"This project is mainly composed of main plant (LF1), radioactive waste treatment center (02) and outdoor projects (including entrances and exits of control areas, entrances and exits of protection areas, security control centers, etc.)."

4.1.2.2总平面布置根据厂区总体规划以及功能分区划分,将主体装置厂房和放射性废物处理中心布置在厂区北侧装置区中部。根据实物保护要求,设置控制区出入口、保护区出入口和保卫控制中心,布置在主体装置厂房的南侧。主体装置厂房外围设置保护区围栏,

主体装置厂房和放射性废物处理中心外围设置控制区围栏。为便于厂区后续工程的建设,本项目子项周围预留发展用地。

"the main plant and radioactive waste treatment center are arranged in the middle of the plant area on the north side of the plant.

"the main plant and radioactive waste treatment center are arranged in the middle of the plant area on the north side of the plant.

According to the physical protection requirements, the entrance and exit of the control area, the entrance and exit of the protection area and the security control center are set up, which are arranged on the south side of the main plant.

Protected area fences are set up around the main plant building, and control area fences are set up around the main plant plant and radioactive waste treatment center.

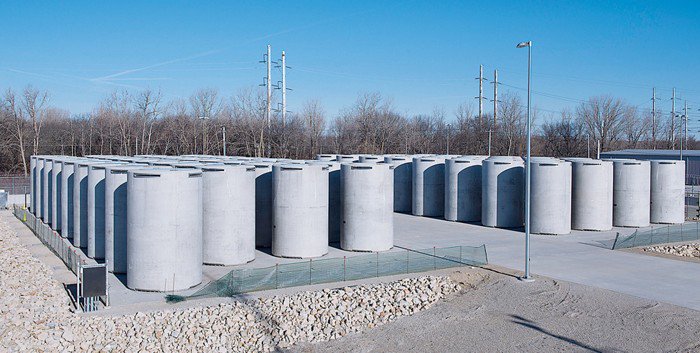

https://twitter.com/ConradKnauer/status/1288620238787862528

In order to facilitate the construction of subsequent projects in the plant area, development land is reserved around the subprojects of this project."

在道路边栽种行道树、花木及加铺草坪等,以改善环境,做到生态保护和美化环境的有机统一。

"Plant street trees, flowers and trees, and turf on the side of the road to improve the environment and achieve the organic unity of ecological protection and beautification of the environment."

"Plant street trees, flowers and trees, and turf on the side of the road to improve the environment and achieve the organic unity of ecological protection and beautification of the environment."

厂区绿地率为30%。

"The green area rate of the plant is 30%."

"The green area rate of the plant is 30%."

https://twitter.com/ConradKnauer/status/1266446200124792834

4.2 反应堆工程概况

"Overview of reactor engineering"

4.2.1概述TMSR-LF1设计热功率为2MW,燃料盐兼做堆芯冷却剂,成分为LiF-BeF2-ZrF4-UF4,燃料盐流经堆芯时产生热量,流经熔盐-熔盐换热器时放出热量。

"TMSR-LF1 is designed with a thermal power of 2MW.

"Overview of reactor engineering"

4.2.1概述TMSR-LF1设计热功率为2MW,燃料盐兼做堆芯冷却剂,成分为LiF-BeF2-ZrF4-UF4,燃料盐流经堆芯时产生热量,流经熔盐-熔盐换热器时放出热量。

"TMSR-LF1 is designed with a thermal power of 2MW.

The fuel salt is also used as a core coolant. The composition is LiF-BeF2-ZrF4-UF4. The fuel salt generates heat when it flows through the core and flows through the molten salt-molten salt exchange. Heat is released when the heater is heated."

TMSR-LF1为一体式反应堆,石墨堆芯和燃料盐回路系统都位于反应堆堆容器中。

"TMSR-LF1 is an integrated reactor. The graphite core and fuel salt loop system are all located in the reactor vessel."

"TMSR-LF1 is an integrated reactor. The graphite core and fuel salt loop system are all located in the reactor vessel."

运行时燃料盐为LiF-BeF2-ZrF4-UF4,其中7Li丰度大于99.95at%,235U富集度为19.75wt%。

"The fuel salt during operation is LiF-BeF2-ZrF4-UF4, in which the 7Li abundance is greater than 99.95%, and the 235U enrichment is 19.75wt%."

"The fuel salt during operation is LiF-BeF2-ZrF4-UF4, in which the 7Li abundance is greater than 99.95%, and the 235U enrichment is 19.75wt%."

冷却盐回路冷却剂使用高7Li丰度的FliBe盐。

"The cooling salt circuit coolant uses FliBe salt with high 7Li abundance."

"The cooling salt circuit coolant uses FliBe salt with high 7Li abundance."

使用石墨作为燃料通道的结构件材料。

"Graphite is used as the structural material of the fuel channel."

"Graphite is used as the structural material of the fuel channel."

使用UNS N10003合金作为主容器及堆内构件的主要合金结构材料。

"UNS N10003 alloy is used as the main alloy structural material for the main vessel and internal components."

"UNS N10003 alloy is used as the main alloy structural material for the main vessel and internal components."

燃料盐的制备合成路线是将符合原料质量标准的UF4、ZrF4、7LiF、BeF2粉料分别按照一定比例混合后,经历熔融共晶和净化工艺流程后,获得高纯的基盐(F7LiBeZr)和添加盐(F7LiU);再以基盐为溶剂,添加盐为溶质进行堆外液液溶解混合形成燃料盐(F7LiBeZrU)后注入堆芯使用。

"The synthesis route of fuel salt is to mix UF4, ZrF4, 7LiF, and BeF2 powders that meet the raw material quality standards in a certain proportion, and then undergo melting eutectic and purification process to obtain high-purity base salt (F7LiBeZr) and add Salt (F7LiU);

The base salt is used as the solvent, and the salt is added as the solute to dissolve and mix with liquid outside the reactor to form a fuel salt (F7LiBeZrU), which is then injected into the reactor core for use."

燃料盐装卸:

" Fuel salt loading and unloading:"

a.通过覆盖气使得堆芯和储罐产生压力差,实现燃料盐的装卸,向临界过渡时则采用胶囊加料的方式。在反应堆装料区,通过气压向堆本体装载燃料,将添加盐储罐内的添加盐(F7LiU)注入装有基盐(F7LiBeZr)的基盐储罐内,

" Fuel salt loading and unloading:"

a.通过覆盖气使得堆芯和储罐产生压力差,实现燃料盐的装卸,向临界过渡时则采用胶囊加料的方式。在反应堆装料区,通过气压向堆本体装载燃料,将添加盐储罐内的添加盐(F7LiU)注入装有基盐(F7LiBeZr)的基盐储罐内,

然后将熔盐在基盐储罐和燃料盐排放罐之间来回倒料,混合均匀,形成均相的燃料盐(F7LiBeZrU)后通过燃料盐装卸管道注入堆芯,燃料盐装卸载通道布置于侧反射层中,由堆顶进入,管道出口位于堆底。燃料盐卸载通过气压将燃料盐从堆芯压入燃料盐排放罐。

"a. The pressure difference between the core and the storage tank is generated by covering the gas to realize the loading and unloading of the fuel salt, and the capsule feeding method is adopted when the transition to the criticality occurs. In the reactor charging area,

the reactor body is loaded with fuel by air pressure, the added salt (F7LiU) in the added salt storage tank is injected into the base salt storage tank containing the base salt (F7LiBeZr), and then the molten salt is placed in the base salt storage tank

Pour materials back and forth between the fuel salt discharge tank and mix evenly to form a homogeneous fuel salt (F7LiBeZrU) and then inject it into the reactor core through the fuel salt loading and unloading pipeline.

The fuel salt loading +unloading channel is arranged in the side reflector layer +enters from the top of the reactor. The pipe outlet is located at the pile bottom. The fuel salt unloading presses the fuel salt from the core into the fuel salt discharge tank by air pressure."

b. TMSR-LF1设有胶囊加料与取样系统,提供向堆内添加燃料和从堆内提取燃料盐样品的功能。

"b. TMSR-LF1 is equipped with a capsule feeding and sampling system, which provides the functions of adding fuel to the reactor and extracting fuel salt samples from the reactor."

"b. TMSR-LF1 is equipped with a capsule feeding and sampling system, which provides the functions of adding fuel to the reactor and extracting fuel salt samples from the reactor."

反应性控制及堆芯功率控制:

"Reactivity control and core power control:"

反应性的控制和停堆是通过控制棒的移动来实现的。使用控制棒设置两套停堆系统,两套停堆系统的控制棒驱动机构不同。堆芯功率控制系统主要实现反应堆的功率控制。堆芯功率控制系统的设计遵守以下原则:

"Reactivity control and core power control:"

反应性的控制和停堆是通过控制棒的移动来实现的。使用控制棒设置两套停堆系统,两套停堆系统的控制棒驱动机构不同。堆芯功率控制系统主要实现反应堆的功率控制。堆芯功率控制系统的设计遵守以下原则:

反应堆的启动及小于20%功率运行时,采用手动控制;在正常运行工况下,反应堆功率在20%-100%额定满功率范围内时,可自动控制;在任何功率水平运行时,均可采用手动控制方式或者由自动控制切换为手动控制;当反应堆处于自动控制时,反应堆可自动跟踪冷却盐回路负荷变化或者克服堆芯反应性扰动。

"Reactivity control and shutdown are realized by the movement of control rods. Two sets of shutdown systems are set up with control rods, and the control rod drive mechanisms of the two shutdown systems are different.

The core power control system mainly realizes the power control of the reactor. The design of the core power control system complies with the following principles: manual control is used when the reactor is started and operating at less than 20% power;

under normal operating conditions, when the reactor power is within the range of 20%-100% of the rated full power, it can be automatically controlled

when operating at any power level, manual control can be used or switched from automatic control to manual control;

when operating at any power level, manual control can be used or switched from automatic control to manual control;

when the reactor is under automatic control, the reactor can automatically track changes in cooling salt circuit load or overcome core reactivity disturbances."

热量产生及传输:

"Heat generation and transmission:"

堆芯、主泵、熔盐/熔盐换热器位于堆容器内,燃料盐流经堆芯时产生热量。正常运行情况下,燃料盐回路燃料盐受循环泵驱动,通过熔盐/熔盐换热器将裂变能从燃料盐回路传递到冷却盐回路,然后冷却盐回路冷却盐受循环泵驱动,

"Heat generation and transmission:"

堆芯、主泵、熔盐/熔盐换热器位于堆容器内,燃料盐流经堆芯时产生热量。正常运行情况下,燃料盐回路燃料盐受循环泵驱动,通过熔盐/熔盐换热器将裂变能从燃料盐回路传递到冷却盐回路,然后冷却盐回路冷却盐受循环泵驱动,

通过熔盐/空气换热器将热量排出到空气环境中。正常停堆情况下,余热经由回路系统最终释放到大气中;回路正常工作的事故情况下,余热经由回路系统最终释放到大气中;回路不能正常工作的事故情况下,利用非能动余热排出系统进行余热排出。

"The core, main pump, and molten salt/molten salt heat exchanger are located in the reactor vessel, and heat is generated when the fuel salt flows through the core. Under normal operating conditions, the fuel salt in the fuel salt circuit is driven by the circulating pump,

and the fission energy is transferred from the fuel salt circuit to the cooling salt circuit through the molten salt/molten salt heat exchanger, and then the cooling salt in the cooling salt circuit is driven by the circulating pump through the molten salt heat exchanger.

The salt/air heat exchanger removes heat into the air environment. In the case of normal shutdown, the waste heat is finally released into the atmosphere through the loop system; in the case of an accident that the loop works normally,

the waste heat is finally released into the atmosphere through the loop system; in the case of an accident that the loop does not work, the passive waste heat removal system is used The waste heat is discharged."

堆本体系统采用强迫循环一体式布局,燃料盐回路整体位于堆本体中,堆本体由内向外主要由以下部分组成:堆芯活性区、反射层、主容器。熔盐/熔盐换热器位于侧反射层内,由上向下依次是:气空间、主泵、上腔室、上支撑板、堆芯、下支撑板、下腔室及流量分配装置。堆芯采用打有燃料盐流道的大块石墨构筑,

堆内金属结构件使用UNS N10003镍基合金材料。控制棒、中子源、实验与测量装置、燃料盐 装卸载通道等布置于堆芯相应的功能通道中。堆本体的功能是容纳整个燃料盐回路,包容燃料盐,在反应堆正常运行期间负责将液态燃料产生的裂变能通过强迫循环经热交换器有效传递到冷却盐回路热力系统,

在停堆状态下能够有效的把反应堆余热通过非能动余热排出系统转移到环境热阱中。

"The reactor body system adopts a forced circulation integrated layout. The fuel salt circuit is located in the reactor body as a whole. The reactor body is mainly composed of the following parts

"The reactor body system adopts a forced circulation integrated layout. The fuel salt circuit is located in the reactor body as a whole. The reactor body is mainly composed of the following parts

from the inside to the outside: the core active area, the reflective layer, and the main container. The molten salt/molten salt heat exchanger is located in the side reflective layer, from top to bottom: air space, main pump, upper chamber, upper support plate, core,

lower support plate, lower chamber and flow distribution device. The reactor core is constructed of large pieces of graphite with fuel salt runners, and the metal structures in the reactor are made of UNS N10003 nickel-based alloy materials.

Control rods, neutron sources, experiment and measurement devices, fuel salt loading and unloading channels, etc. are arranged in the corresponding functional channels of the core. The function of the reactor body is to contain the entire fuel salt circuit and the fuel salt.

During the normal operation of the reactor, it is responsible for effectively transferring the fission energy generated by the liquid fuel to the cooling salt circuit thermal system through the forced circulation through the heat exchanger.

The reactor waste heat is effectively transferred to the environmental heat sink through the passive waste heat removal system."

燃料2MWt液态燃料钍基熔盐实验堆(TMSR-LF1) 采用四氟化铀(UF4,U-235的富集度为19.75wt%)作为核燃料,使用时首先将其进行预处理形成添加盐(LiF-UF4,72-28 mol.%),然后将添加盐溶解在基盐(LiF-BeF2-ZrF4,65-30-5 mol.%)内形成均相燃料盐,形成的燃料盐作为堆芯燃料兼冷却剂使用。

"The fuel 2MWt liquid fuel thorium-based molten salt experimental reactor (TMSR-LF1) uses uranium tetrafluoride (UF4, the enrichment of U-235 is 19.75wt%) as nuclear fuel, and it is first pretreated to form added salt ( LiF-UF4, 72-28 mol.%),

and then the added salt is dissolved in the base salt (LiF-BeF2-ZrF4, 65-30-5 mol.%) to form a homogeneous fuel salt, and the formed fuel salt is used as the core Use of fuel and coolant. "

反应堆寿期内,燃料盐一直处于堆内运行,不进行处理和回收。

"During the life of the reactor, the fuel salt has been running in the reactor without processing and recycling."

"During the life of the reactor, the fuel salt has been running in the reactor without processing and recycling."

安全系统2MWt液态燃料钍基熔盐实验堆的固有安全性如下:(1)反应堆具有较大负的反应性温度系数,在反应堆温度上升的情况下可以引入负的反应性,温度升高到一定程度可自动停堆;(2)反应堆包含大量的石墨与熔盐,有很大的热容量,堆芯有很大的热惰性,对瞬变有很强的适应能力,事故进程缓慢;

(3)在事故工况下,反应堆采用非能动余热排出系统,利用热辐射、热传导、空气自然循环带出堆内余热;(4)对于放射性具有多重实体包容屏障,包括:燃料盐和覆盖气边界、安全容器;(5)熔盐对于部分放射性物质有滞留作用,如137Cs等,防止其扩散到大气中。

Safety system The inherent safety of the 2MWt liquid fuel thorium-based molten salt experimental reactor is as follows: (1) The reactor has a large negative temperature coefficient of reactivity, and negative reactivity can be introduced when the reactor temperature rises.

The reactor can be shut down automatically to a certain level; (2) The reactor contains a large amount of graphite and molten salt, has a large heat capacity, the core has a large thermal inertia, has a strong ability to adapt to transients, and the accident progress is slow;

(3) Under accident conditions, the reactor adopts a passive waste heat removal system, which uses heat radiation, heat conduction, and natural air circulation to bring out the waste heat in the reactor; (4) There are multiple physical containment barriers for radioactivity,

including: fuel salt and cover gas Boundaries and safety containers; (5) Molten salt has a retention effect on some radioactive substances, such as 137Cs, etc., to prevent them from spreading into the atmosphere."

2MWt液态燃料钍基熔盐实验堆专设安全系统包括非能动余热排出系统和安全容器。

"The 2MWt liquid fuel thorium-based molten salt experimental reactor has a special safety system including a passive waste heat removal system and a safety container."

"The 2MWt liquid fuel thorium-based molten salt experimental reactor has a special safety system including a passive waste heat removal system and a safety container."

1.非能动余热排出系统非能动余热排出系统的安全功能是在发生事故下(燃料盐、冷却盐回路无法正常运转),不能通过熔盐-空气换热器将热量排出的情况下,将反应堆的余热排至最终的大气热阱,保证燃料盐边界处于可接受的温度限制范围内。

"1. Passive waste heat removal system The safety function of the passive waste heat removal system is to remove the heat from the reactor in the event of an accident ([if] the fuel salt and cooling salt circuits cannot operate normally)

and the heat cannot be discharged through the molten salt-air heat exchanger. The waste heat is discharged to the final atmospheric heat sink to ensure that the fuel salt boundary is within the acceptable temperature limit."

事故前期的堆内热量可依靠堆本体与回路系统自身的热容包容。事故分析表明反应堆满功率的2%作为非能动余热排出系统的余热排出能力,可实现事故全程堆内余热的持续导出,使燃料盐边界温度在限值内,从而保证反应堆的安全。

"The heat in the reactor in the early stage of the accident can be contained by the heat capacity of the reactor body and the loop system itself. The accident analysis showed that 2% of the reactor's full power was used as the waste heat removal capacity of

the passive waste heat removal system, which can realize the continuous output of the waste heat in the reactor throughout the accident, and keep the fuel salt boundary temperature within the limit, thereby ensuring the safety of the reactor."

非能动余热排出系统的运行不需要借助能动部件的动作,只依靠非能动的方式即可将反应堆余热从堆容器壁面带到最终热阱——大气,具有结构简单,安装维修方便,故障率低等特点。

"The operation of the passive waste heat removal system does not need to rely on the action of active parts. It can only rely on passive means to bring the reactor waste heat from the wall of the reactor vessel to the final heat sink-atmosphere.

It has simple structure, convenient installation and maintenance, and low failure rate."

非能动余热排出系统由进风管、换热装置、出风管、排气塔组成。在事故工况下,首先借助热传导、自然对流换热和热辐射等非能动的自然机制,依次通过石墨反射层和堆容器,将反应堆余热排出到堆舱中;然后,绝大部分热量通过堆舱内非能动余热排出系统的换热装置排向最终热阱。

"The passive waste heat exhaust system is composed of air inlet pipe, heat exchange device, air outlet pipe and exhaust tower. Under accident conditions, firstly, by means of passive natural mechanisms such as heat conduction, natural convection heat transfer, and heat radiation,

the reactor waste heat is discharged into the reactor cabin through the graphite reflective layer and the reactor container in turn; then, most of the heat passes through the reactor

The heat exchange device of the passive waste heat removal system in the cabin is discharged to the final heat sink."

安全容器是包容反应堆及有关相连系统并在反应堆事故状态下,防止不可接受的放射性物质向环境释放的容器,是包容反应堆堆芯放射性物质的最后一道屏障。将失效后会导致放射性物质不可控释放的系统和部件置于安全容器内,将释放到环境的放射性核素限制在可接受的限值内,以满足国家规定剂量限值要求,

尽量减少正常运行工况和事故工况时附近人员受到的照射。

"The safety container is a container that contains the reactor and related connected systems and prevents the release of unacceptable radioactive materials to the environment in the event of a reactor accident.

"The safety container is a container that contains the reactor and related connected systems and prevents the release of unacceptable radioactive materials to the environment in the event of a reactor accident.

It is the last barrier to contain the radioactive materials in the reactor core. Place the systems and components that will cause uncontrolled release of radioactive materials after failure in a safe container,

and limit the radionuclides released into the environment within acceptable limits to meet the national dose limit requirements and minimize normal operation exposure to nearby personnel during operating conditions and accident conditions."

2MWt液态燃料钍基熔盐实验堆(TMSR-LF1)的实验装置为“堆内实验样品输送装置”,其功能为将实验样品通过传输机构送到深入堆本体内部的套管中进行辐照(样品本身位于大气环境,通过“堆本体部件——套管”与堆内熔盐隔绝)。

"[TMSR-LF1 has an] "in-reactor experimental sample transport device", whose function is to send the experimental sample through the transmission mechanism to the casing deep into the reactor body for irradiation

( The sample itself is located in the atmospheric environment, and is isolated from the molten salt in the stack by the "stack body part-casing").

装置主要包括实验样品提升组件和气路系统等结构

"The device mainly includes the structure of the experimental sample lifting component and the gas path system."

"The device mainly includes the structure of the experimental sample lifting component and the gas path system."

进堆时,样品从测量间装入管道,在正压气体作用下,样品通过气动输送管道滑落至接样装置,到达接样装置后,卷筒钢丝绳将样品输送至辐照位置;出堆时,钢丝绳将接样装置提升到接样装置,气动管道通入气体,将样品吹入气动输送管道,进而将样品输送至测量间。

"When entering the stack, the sample is loaded into the pipeline from the measurement room, and under the action of positive pressure gas, the sample slides down to the sample receiving device through the pneumatic conveying pipe.

After reaching the sample receiving device, the drum wire rope transports the sample to the irradiation position; the steel wire rope lifts the sample receiving device to the sample receiving device, the pneumatic pipe is fed with gas,

the sample is blown into the pneumatic conveying pipe, and then the sample is transported to the measurement room.

装置本身具有气密性,不对反应堆的包容边界构成影响,不造成计划外的反应性引入,不对反应堆的运行构成影响。

装置本身具有气密性,不对反应堆的包容边界构成影响,不造成计划外的反应性引入,不对反应堆的运行构成影响。

"The device itself is airtight, does not affect the containment boundary of the reactor, does not cause unplanned reactivity to be introduced, and does not affect the operation of the reactor."

采用悬挂式超细干粉灭火系统保护控制区冷却盐回路泵稀油站油箱间可能发生的火灾,灭火装置自带感温元件,当环境温度上升至68°C时,灭火装置自动启动并释放超细干粉灭火剂。

"Suspended ultra-fine dry powder fire extinguishing system is used to protect the control area of the possible fire between the cooling salt circuit pump and the oil tank of the thin oil station. The fire extinguishing device has its own temperature sensing element.

When the ambient temperature rises to 68 °C, the fire extinguishing device will automatically start and release the super Fine dry powder fire extinguishing agent."

4.4.2 排热系统

"Heat rejection system"

设备冷却水系统是一个非安全级的闭式回路冷却系统,将LF1主体装置厂房各类发热设备的热量通过设冷水系统传递到冷冻水,并通过冷冻水系统的冷冻机组最终传递到环境中。

"Heat rejection system"

设备冷却水系统是一个非安全级的闭式回路冷却系统,将LF1主体装置厂房各类发热设备的热量通过设冷水系统传递到冷冻水,并通过冷冻水系统的冷冻机组最终传递到环境中。

"The equipment cooling water system is a non-safety-level closed loop cooling system, which transfers the heat of various heating equipment in the main plant of LF1 to the chilled water through the chilled water system,

and finally to the environment through the chiller unit of the chilled water system."

需要设备冷却水系统导出热量的设备包括:燃料盐回路/冷却盐回路真空系统泵、气路系统尾气处理设备、熔盐制备系统真空泵和冷却盐回路稀油站。

需要设备冷却水系统导出热量的设备包括:燃料盐回路/冷却盐回路真空系统泵、气路系统尾气处理设备、熔盐制备系统真空泵和冷却盐回路稀油站。

"The equipment that requires the equipment cooling water system to export heat includes: fuel salt circuit/cooling salt circuit vacuum system pump, gas system exhaust gas treatment equipment, molten salt preparation system vacuum pump and cooling salt circuit thin oil station."

设备冷却水系统设有两个机械系列,每个系列包含一台设备冷却水泵和一台设备冷却水热交换器。

"The equipment cooling water system has two mechanical series, each series includes an equipment cooling water pump and an equipment cooling water heat exchanger."

"The equipment cooling water system has two mechanical series, each series includes an equipment cooling water pump and an equipment cooling water heat exchanger."

两个系列共用一台波动箱,从公共的回水母管上吸水。

"The two series share a wave box, which sucks water from the common return pipe."

波动箱连接在两台泵公共的取水母管上。

"The wave box is connected to the common water pipe of the two pumps."

"The two series share a wave box, which sucks water from the common return pipe."

波动箱连接在两台泵公共的取水母管上。

"The wave box is connected to the common water pipe of the two pumps."

每台泵与各自的热交换器直接连接,中间设交叉管线,可根据需要实现交叉供水。

"Each pump is directly connected with its own heat exchanger, with cross pipelines in the middle, which can realize cross water supply as required."

"Each pump is directly connected with its own heat exchanger, with cross pipelines in the middle, which can realize cross water supply as required."

当波动箱液位偏低时,通过除盐水分配系统从纯水箱进行补水。

"When the liquid level of the surge tank is low, water is supplied from the pure water tank through the desalinated water distribution system."

"When the liquid level of the surge tank is low, water is supplied from the pure water tank through the desalinated water distribution system."

从潜在放射性区域排放的空气不能进行再循环;没有污染的空气可以从屋顶或墙上的通风口直接排至室外大气中;所有可能来自污染区的空气,在排放之前要进行监测,

"The air discharged from the potentially radioactive area cannot be recycled; the unpolluted air can be directly discharged into the outdoor atmosphere from the roof or wall vents; all the air that may come from the polluted area should be monitored before being discharged."

控制区有HF危险的房间每小时换气次数为12次/h。

"The number of air changes per hour in [rooms] with HF risk in the control area is 12 times/h.

"The number of air changes per hour in [rooms] with HF risk in the control area is 12 times/h.

LF1厂房的温湿度、通风换气及洁净要求通过以下不同的供热、通风与空调系统(HVAC)来完成的,

"The temperature, humidity, ventilation and cleanliness requirements of the LF1 plant are completed by [nine] different heating, ventilation and air conditioning systems (HVAC)"

"The temperature, humidity, ventilation and cleanliness requirements of the LF1 plant are completed by [nine] different heating, ventilation and air conditioning systems (HVAC)"

LF1厂房所有通风系统均属于非核级系统,所属设备均为非核级设备。

"All ventilation systems in the LF1 plant are non-nuclear-level systems, and their equipment is non-nuclear-level equipment."

"All ventilation systems in the LF1 plant are non-nuclear-level systems, and their equipment is non-nuclear-level equipment."

本项目采用两路10kV市电电源作为正常工作电源,为回路系统、堆本体测量、堆本体控制棒、辐射安全、仪控系统、化学安全、消防水泵、实体保卫、除盐水制备、采暖通风、冷冻水、气体、熔盐制备、放废管理、给排水等工艺设备的用电负荷供电。

"This project uses two 10kV mains power supplies as normal working power sources, including loop system, reactor body measurement, reactor body control rods, radiation safety, instrument control system, chemical safety, fire pumps, physical security,

desalinated water preparation, heating and ventilation, Power supply for electrical loads of process equipment such as chilled water, gas, molten salt preparation, waste management, water supply and drainage."

为确保消防类和生产重要负荷的正常运行,基地在双路供电基础上采用柴油发电机作为备用电源。柴油发电机组的容量较大,持续供电时间长,不受电网故障的影响,可靠性较高。

"In order to ensure the normal operation of important fire-fighting and production loads, the base uses

"In order to ensure the normal operation of important fire-fighting and production loads, the base uses

diesel generators as backup power sources on the basis of dual power supply. Diesel generator sets have a large capacity, a long continuous power supply time, and are not affected by grid failures and have high reliability."

同时,对于全厂断电后仍需供电1或2小时的辐射安全监测仪表、熔盐制备中控柜、仪控系统保护及控制柜等负荷采用UPS1供电,对于全厂断电后仍需供电12小时的事故后监测仪、堆外核测柜、保护主处理柜、保护系统安全屏等负荷采用UPS2、UPS3供电。

"At the same time, UPS1 is used to supply power for loads such as radiation safety monitoring instruments, molten salt preparation central control cabinets, instrument control system protection and control cabinets that still need

power supply for 1 or 2 hours after the power is cut off. The 12-hour post-accident monitor, off-stack nuclear test cabinet, protection main processing cabinet, and protection system safety screen are powered by UPS2 and UPS3."

每套UPS的充电器上游电源引自柴油机应急母线段,旁路变压器上游电源引自正常低压母线段。如果全厂断电,每套蓄电池组仍能提供满足负荷需求的电源,可靠性较高。本项目主体装置厂房内布置有变配电室、蓄电池间、柴油发电机间等设施,用于保障本项目正常用电。

"The upstream power supply of the charger of each UPS is drawn from the emergency bus section of the diesel engine, and the upstream power supply of the bypass transformer is drawn from the normal low-voltage bus section. If the whole plant is powered off, each

battery pack can still provide power to meet the load demand with high reliability. The main plant of the project is equipped with facilities such as a transformer room, a storage battery room, and a diesel generator room to ensure the normal power consumption of the project."

Section 4.7.2 is about the "Radioactive waste gas management system"

控制I、II、III区和禁止进入区域的排风经空气过滤器净化处理后,在堆厂房经烟囱进行大气排放。

"After the exhaust air in the control areas I, II, III and prohibited areas is purified by air filters, it is discharged into the atmosphere through the chimney in the stack building."

"After the exhaust air in the control areas I, II, III and prohibited areas is purified by air filters, it is discharged into the atmosphere through the chimney in the stack building."

正常工况下,维持整个厂房负压以尽可能地将污染空气的向外泄漏降至最低。

"Under normal working conditions, maintain the negative pressure of the entire plant to minimize the leakage of polluted air to the outside."

"Under normal working conditions, maintain the negative pressure of the entire plant to minimize the leakage of polluted air to the outside."

TL;DR version of this section:

本项目新燃料运输仅涉及添加盐,燃料盐由添加盐和基盐在临堆燃料装卸区混合后直接入堆,无需输运。

"The new fuel transportation of this project only involves adding salt, and the fuel salt is mixed directly into the reactor after adding salt and base salt in the fuel loading

"The new fuel transportation of this project only involves adding salt, and the fuel salt is mixed directly into the reactor after adding salt and base salt in the fuel loading

and unloading area near the reactor, without transportation."

在2MWt液态燃料钍基熔盐实验堆寿期内,燃料盐一直在堆内运行,不形成另外的乏燃料盐,在反应堆退役前,无需考虑乏燃料的厂内运输问题。

"During the life of the 2MWt liquid fuel thorium-based molten salt experimental reactor,

在2MWt液态燃料钍基熔盐实验堆寿期内,燃料盐一直在堆内运行,不形成另外的乏燃料盐,在反应堆退役前,无需考虑乏燃料的厂内运输问题。

"During the life of the 2MWt liquid fuel thorium-based molten salt experimental reactor,

the fuel salt has been running in the reactor without forming additional spent fuel salt. Before the reactor is decommissioned, there is no need to consider the transportation of spent fuel in the plant."

对反应堆来说,退役是继选址、设计、建造、试运行和运行之后的最后一个阶段。

"For the reactor, decommissioning is the last stage after site selection, design, construction, trial operation and operation."

"For the reactor, decommissioning is the last stage after site selection, design, construction, trial operation and operation."

目前越来越多的反应堆退役研究和经验表明,必须在设计、建造和运行阶段就对将来反应堆的退役进行充分考虑。

"At present, more and more research and experience... show that the future decommissioning of reactors must be fully considered in the design, construction + operation stages."

"At present, more and more research and experience... show that the future decommissioning of reactors must be fully considered in the design, construction + operation stages."

退役拆除阶段,按照确定的退役顺序,对存在放射性的厂房内物项进行拆除。拆除时对于放射性水平较高的部件(如反应堆容器、堆内构件、石墨组件等)采取远距离遥控解体的拆除方式;对于受污染较重设备(如熔盐-熔盐换热器、主泵等),

可将其整体移至适当位置进行解体,尽量选择冷切割工具,当冷切割不能满足切割要求时,辅以热切割方式,并在热切割工位旁设置移动式通风装置,为了减少人员辐照剂量或降低工作人员劳动强度,可选择使用机器人或自动切割设备进行切割拆除等操作;

"In the decommissioning and dismantling phase, the items in the factory building with radioactivity shall be dismantled [...] When dismantling, the components with high radioactivity level (such as reactor vessel, internal components, graphite components, etc.)

shall be dismantled remotely [...] for heavy contaminated equipment (such as molten salt-molten salt heat exchanger, main pump, etc.), it can be moved to a proper position for disassembly. Try to choose cold cutting tools.

When cold cutting cannot meet the cutting requirements, use hot cutting methods, and install a mobile ventilation device next to the hot cutting station

to reduce personnel irradiation dose or reduce the labor intensity of the staff, you can choose to use robots or automatic cutting equipment for cutting and dismantling operations"

Decommissioning section mentions 在反应堆运行的十年期间 "the ten years of reactor operation" IOW until ~2030; cf.

https://twitter.com/ConradKnauer/status/1344971600165179392

Table 4.1-1 has info on the site:

Total land area 12.802 hm^2

Total building area

Above ground 9031.11 m^2

Underground 2561.123 m^2

Floor area of buildings +structures 5342.004 m^2

Green space 30%

Fence length

Control area 761.10m

Protected area 973.10m

Total land area 12.802 hm^2

Total building area

Above ground 9031.11 m^2

Underground 2561.123 m^2

Floor area of buildings +structures 5342.004 m^2

Green space 30%

Fence length

Control area 761.10m

Protected area 973.10m

Note "Total length of double fences"

and "The area of the road square is included in the supporting project of the thorium-based molten salt reactor nuclear energy system experimental platform."

https://twitter.com/ConradKnauer/status/1288620238787862528

and "The area of the road square is included in the supporting project of the thorium-based molten salt reactor nuclear energy system experimental platform."

Section 5.1.3.5 talks about noisy machinery during construction (this is a VERY detailed environmental assessment!), e.g. pile drivers (95-105dB), concrete mixer (75-88dB), large transportation equipment (80-85dB).

https://twitter.com/ConradKnauer/status/1345251562667405312

"Figure 5.4-1 Layout of the current environmental quality inspection points during the construction period"

(this looks like a Google image :)

(this looks like a Google image :)

"Table 6.1-3 The contribution of the nuclides discharged from the airborne effluent of this project to the dose of key residents through various channels" is interesting; there are basically only two that cause almost the entire exposure...

Argon-41 (6.85E-08 Sv/year; ~13%) by "Air immersion"

Tritium (4.65E-07 Sv/year; ~87%) by inhilation

The Argon appears to be from neutron activation of the cover gas; the tritium is from the FLiBe, and is a known issue.

Tritium (4.65E-07 Sv/year; ~87%) by inhilation

The Argon appears to be from neutron activation of the cover gas; the tritium is from the FLiBe, and is a known issue.

根据FSAR的分析结果,TMSR-LF1可能造成放射性释放的设计基准事故主要有:—燃料盐覆盖气体系统边界泄漏事故;—熔盐-熔盐换热管侧泄漏事故;

"According to the analysis results of FSAR, the design basis accidents that TMSR-LF1 may cause radioactive release mainly include:

-fuel salt covering gas system boundary leakage accident

-molten salt-molten salt heat exchange tube side leakage accident"

-fuel salt covering gas system boundary leakage accident

-molten salt-molten salt heat exchange tube side leakage accident"

发生熔盐-熔盐换热器管侧泄漏假想事故时,TMSR-LF1控制棒停堆系统的功能和非能动余热排出系统的功能不受影响,因此,反应堆可安全停堆。在反应堆正常运行时,TMSR-LF1冷却盐回路的压力高于燃料盐回路的压力。

"In the event of a hypothetical accident of leakage on the tube side of the molten salt-molten salt heat exchanger, the function of the TMSR-LF1 control rod shutdown system and the function of the passive waste heat removal system will not be affected.

Therefore, the reactor can be shut down safely. During normal operation of the reactor, the pressure of the TMSR-LF1 cooling salt circuit is higher than the pressure of the fuel salt circuit."

因此,当发生熔盐-熔盐换热器传热管假想泄漏时,冷却盐向燃料盐回路系统泄漏。当冷却盐泄漏进入燃料盐回路系统时,反应性下降,堆芯燃料盐液位升高,覆盖气压力升高,冷却盐泵罐液位下降。当燃料盐回路中液位下降至预定值时,液位监测系统提示操纵员干预。

"Therefore, when hypothetical leakage of the heat transfer tube of the molten salt-molten salt heat exchanger occurs, the cooling salt leaks to the fuel salt circuit system. When the cooling salt leaks into the fuel salt circuit system, the reactivity drops,

the fuel salt level in the core rises, the cover gas pressure rises, and the cooling salt pump tank liquid level drops. When the liquid level in the fuel salt circuit drops to a predetermined value, the liquid level monitoring system prompts the operator to intervene."

即使操纵员没有及时采取措施,冷却盐向燃料盐回路泄漏引起燃料盐回路裂变燃料浓度下降,进而引起反应性下降。当调节棒不足以补偿反应性的持续降低时,链式反应自动停止,反应堆安全停堆。该事故情景中,反应堆非能动余热排出系统始终处于工作状态,余热被安全导出。

"Even if the operator does not take timely measures, the leakage of the cooling salt to the fuel salt circuit will cause the fission fuel concentration of the fuel salt circuit to decrease, which in turn causes the reactivity to decrease.

When the regulating rod is insufficient to compensate for the continuous decrease in reactivity, the chain reaction automatically stops and the reactor is safely shut down.

In this accident scenario, the passive waste heat removal system of the reactor is always in working condition, and the waste heat is safely exported."

本项目在建设和运行中将使用各类易燃易爆和有毒的油与化学品,如果处理不善可能出现爆炸、火灾以及危险品泄漏事故,

(A reminder that not all reactor hazards are nuclear ;)

"Various [non-radioactive] flammable, explosive +toxic oils +chemicals will be used in the construction +operation of this project. If not handled properly, explosions, fires +dangerous goods leakage accidents may occur."

"Various [non-radioactive] flammable, explosive +toxic oils +chemicals will be used in the construction +operation of this project. If not handled properly, explosions, fires +dangerous goods leakage accidents may occur."

主控制室正常运行情况下,主控制室是实施TMSR-LF1实验堆集中运行控制和监测的场所,事故工况下,主控制室是应急运行组的工作场所。

"Under the normal operation... the main control room is the place where the centralized operation control and monitoring of the TMSR-LF1 experimental reactor is implemented. Under accident conditions, the main control room is the workplace of the emergency operation team."

"Figure 8.1-2 Plan view of airborne effluent monitoring points"

This appears to be the LF1 building, and the thick walled-area almost certainly will house the reactor.

This appears to be the LF1 building, and the thick walled-area almost certainly will house the reactor.

I note "CRESDA" mentioned in the lower left corner; desktop.arcgis.com/en/arcmap/10.3… says:

"The ZY3-CRESDA raster type allows you to add raster data collected from the ZY3 satellite, which is distributed by China Centre for Resources Satellite Data and Application."

"The ZY3-CRESDA raster type allows you to add raster data collected from the ZY3 satellite, which is distributed by China Centre for Resources Satellite Data and Application."

directory.eoportal.org/web/eoportal/s… describes the satellite:

"ZY-3A (Resource-3A) is the first civil high-resolution stereoscopic Earth mapping satellite of China. [...] The mission requirements call for high-accuracy mapping."

"ZY-3A (Resource-3A) is the first civil high-resolution stereoscopic Earth mapping satellite of China. [...] The mission requirements call for high-accuracy mapping."

图8.1-7 γ辐射剂量率连续监测点位示意图

"Figure 8.1-7 Schematic diagram of continuous monitoring points for gamma radiation dose rate"

"Figure 8.1-7 Schematic diagram of continuous monitoring points for gamma radiation dose rate"

图8.1-8 厂界内氚监测位置示意图

"Figure 8.1-8 Schematic diagram of tritium monitoring location within the plant boundary"

"Figure 8.1-8 Schematic diagram of tritium monitoring location within the plant boundary"

And that's basically the end!

@threadreaderapp unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh