Valiant organics AR-

You would be delighted to know that we completed the

expansion of ammonolysis capacity at Vapi plant. We also completed expansion of Phase I of Para Amino Phenol (PAP),while the expansion of Ortho Amino Phenol (OAP) is still in process.

You would be delighted to know that we completed the

expansion of ammonolysis capacity at Vapi plant. We also completed expansion of Phase I of Para Amino Phenol (PAP),while the expansion of Ortho Amino Phenol (OAP) is still in process.

-PAP has been identified as key intermediates of

pharmaceutical products.

We have commenced preparation on the production of drug intermediates. Our strategy is to produce drug intermediates to reduce the imports of these products.

pharmaceutical products.

We have commenced preparation on the production of drug intermediates. Our strategy is to produce drug intermediates to reduce the imports of these products.

On the other hand, we have been increasingly considering forward integration

of Paracetamol in the future. All these will enable us to

cater to the growing demand for drug intermediates

and APIs in the end-user industries, particularly, the

pharmaceuticals industry

of Paracetamol in the future. All these will enable us to

cater to the growing demand for drug intermediates

and APIs in the end-user industries, particularly, the

pharmaceuticals industry

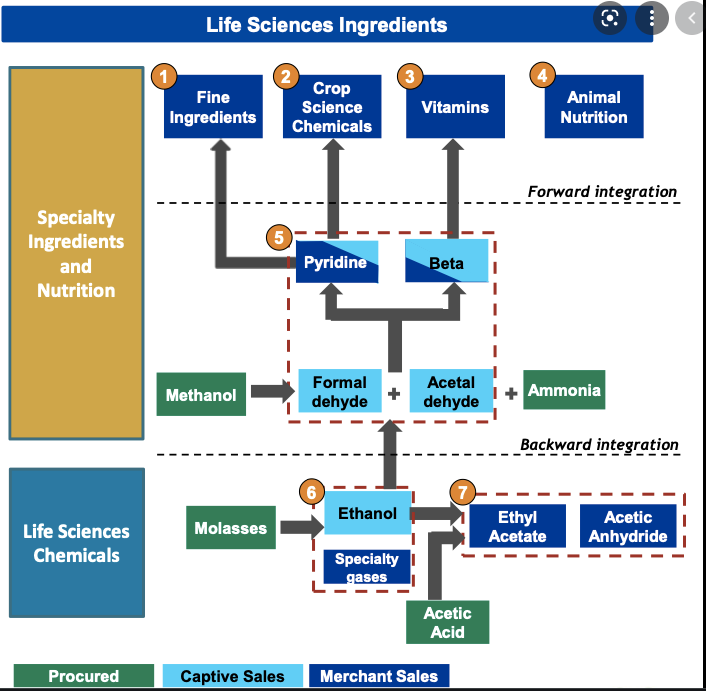

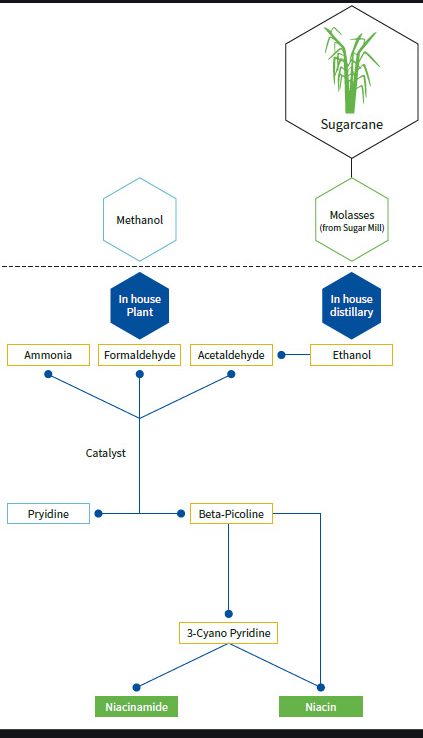

The backward integration at the Jhagadia plant helped the Company manufacture its raw materials in-house, enabling the Company to reduce the dependence on suppliers and giving it a great cost and time advantage, in addition to ensuring better

quality control.

quality control.

The Company has focussed on hydrogenation expansion,which has reduced its dependence on buying Ortho Nitro Anisole / Para Nitro Anisole from vendors. This expansion has enabled the Company to attain captive consumption of the afore

mentioned material for manufacturing Ortho Anisidine /Para Anisidine.

-Earlier, the Company used to generate solid waste containing 2,4,6 Trichloro phenol

(246TCP). With its sharp focus on sustainability, the Company introduced process to separate out 246TCP from the wastage,

-Earlier, the Company used to generate solid waste containing 2,4,6 Trichloro phenol

(246TCP). With its sharp focus on sustainability, the Company introduced process to separate out 246TCP from the wastage,

and scaled it to make it a saleable product, over the years. The Company has also focussed on implementing DistributionControl System (DCS) across all plants, empowering automation

and safety systems in the facilities. This is also expected to enhance the plant efficiencies.

and safety systems in the facilities. This is also expected to enhance the plant efficiencies.

• • •

Missing some Tweet in this thread? You can try to

force a refresh