Alicon Castalloy Ltd-

History

-ACL was established as Enkei Castalloy Ltd (Enkei Castalloy), a joint venture between Pegasus Castalloy Ltd (an Indian company that manufactures cast-aluminium automotive components since 1990) and Enkei Corporation (in Japan; one of the largest

History

-ACL was established as Enkei Castalloy Ltd (Enkei Castalloy), a joint venture between Pegasus Castalloy Ltd (an Indian company that manufactures cast-aluminium automotive components since 1990) and Enkei Corporation (in Japan; one of the largest

manufacturers of alloy wheels in the world). Owing to sustained losses in the alloy wheels division, the promoters hived it off as a separate company, Enkei Wheels Ltd, and retained the casting business with effect from April 1, 2009.

- Enkei Castalloy was renamed as ACL on December 27, 2010.

-Manufacturing Plants

1- Shikrapur- Maharashtra,

2-Chinchwad in Maharashtra

3- Binola in Haryana

4- international plant is in Slovakia

-Manufacturing Plants

1- Shikrapur- Maharashtra,

2-Chinchwad in Maharashtra

3- Binola in Haryana

4- international plant is in Slovakia

-Promotors holding around 55% ( Its down from March q due to QIP at 535 Rs)CFO sold some shares .

-Past performance in last few q is not good but still i bought some quantities because my view is that its growing business in

Customers-

-Past performance in last few q is not good but still i bought some quantities because my view is that its growing business in

Customers-

EV segment will drive its earnings

Business segments-

1-Auto Business

Supplying aluminium casting solutions to major local and many international OEMs in the automotive sector like

Business segments-

1-Auto Business

Supplying aluminium casting solutions to major local and many international OEMs in the automotive sector like

~cylinder head ( Flafship offering )

~suspension parts

~ wheel hubs

~bridge fork top

~ outer tubes

~ inlet pipes,

~suspension parts

~ wheel hubs

~bridge fork top

~ outer tubes

~ inlet pipes,

In recent years, the sector’s thrust has been on reducing overall vehicle weight to improve fuel economy. The challenge is to make light-weighted components with aim of safety and cost effectiveness so i feel it will drive growth of aluminum casting

Read comment of management-

-With the BS-VI regime in India, we are also

supplying our customers with suspension

parts and other relevant offerings, in addition

to cylinder heads. With this, our content per

vehicle will go up by 18-20% in FY 2021-22.

-With the BS-VI regime in India, we are also

supplying our customers with suspension

parts and other relevant offerings, in addition

to cylinder heads. With this, our content per

vehicle will go up by 18-20% in FY 2021-22.

2- EV segment -

Aluminium and other low-density materials enable a weight reduction of the component as much as 46%, enabling EV efficiencies.

Additionally, as vehicles are converted from ICE

to EV platform, it is anticipated that aluminium usage will see a 2-2.5-fold increase

Aluminium and other low-density materials enable a weight reduction of the component as much as 46%, enabling EV efficiencies.

Additionally, as vehicles are converted from ICE

to EV platform, it is anticipated that aluminium usage will see a 2-2.5-fold increase

per vehicle.

~Company is already supplying battery housing to Samsung who supply onward to JLR in the EV space. ~ ~ Company also received orders from Dana Corporation, Mahindra & Mahindra, Graziano

and Ashwood for their e-mobility platforms.

~Company is already supplying battery housing to Samsung who supply onward to JLR in the EV space. ~ ~ Company also received orders from Dana Corporation, Mahindra & Mahindra, Graziano

and Ashwood for their e-mobility platforms.

If you see in AR their target is to clock

25% of revenues from E-mobility by FY 2025-26 but in latest concall their target increased to 36%

Read My thread about Aluminum in EV

25% of revenues from E-mobility by FY 2025-26 but in latest concall their target increased to 36%

Read My thread about Aluminum in EV

https://twitter.com/drprashantmish6/status/1466765457390776322?s=20

3-Non-Auto Business

Non Auto Business like sectors such as

defence, aerospace, agriculture and energy, there is a growing demand for light-weighted components.

-For instance, the Indian defence sector is currently refurbishing tank wheels with lightweight aluminium parts

Non Auto Business like sectors such as

defence, aerospace, agriculture and energy, there is a growing demand for light-weighted components.

-For instance, the Indian defence sector is currently refurbishing tank wheels with lightweight aluminium parts

to lower the tank’s overall weight.

According to management with Low-Pressure Die Casting process they are the only Indian supplier for these wheels.

~are also supplying cylinder heads for defence trucks.

According to management with Low-Pressure Die Casting process they are the only Indian supplier for these wheels.

~are also supplying cylinder heads for defence trucks.

~The Company has received orders from Honeywell Automation India and ABB India as they expand their businesses in the domestic and export markets.

~The Company has also bagged repeat business win from Ingersoll Rand for supplying their products in the China market.

~

~The Company has also bagged repeat business win from Ingersoll Rand for supplying their products in the China market.

~

~The Company is also expecting an order from

BEML for supplying cylinder heads for the 10,000 TATA trucks

BEML for supplying cylinder heads for the 10,000 TATA trucks

In agriculture, aluminum components are being used by tractors

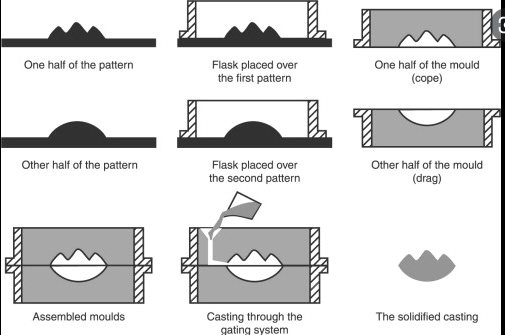

~Read My thread to gain some basic knowledge about various Aluminum casting methods which we should know as a investor

~Read My thread to gain some basic knowledge about various Aluminum casting methods which we should know as a investor

https://twitter.com/drprashantmish6/status/1466808123792891906?s=20

4-Technology agonistic solution -

~Company is getting increased enquiries from several OEMs for the development of frames and control arms following their successful completion of the order with (JLR) / global OEM for the same product basket.

~Company is getting increased enquiries from several OEMs for the development of frames and control arms following their successful completion of the order with (JLR) / global OEM for the same product basket.

~As chassis, suspension, frames and control arms and other parts are increasingly made from aluminium to stay ahead of technological disruption, comapany anticipate that the aluminium contribution in a four-wheeler will increase from 30 Kg to around 100 Kgs.

5-Solution Provider -

In EVs, components like motors

and batteries generate considerable heat

during operation, which impacts the

end-product performance,They have recently

devised a thermal engineering solution for EVs, through European Subsidiary for that .

In EVs, components like motors

and batteries generate considerable heat

during operation, which impacts the

end-product performance,They have recently

devised a thermal engineering solution for EVs, through European Subsidiary for that .

They have already partnered with Bosch and Samsung/ e-mobility technology leaders for these thermal management solutions and have gained significant exposure in the European markets.

Some Points from Latest Concall

~exports including overseas revenues contributed to 25% of the total revenue while domestic contribution was 75%.

~Across verticals, the Auto Division

contributed to 94% of the total revenue in Q2 FY22 and Non-auto Division was at 6%

~exports including overseas revenues contributed to 25% of the total revenue while domestic contribution was 75%.

~Across verticals, the Auto Division

contributed to 94% of the total revenue in Q2 FY22 and Non-auto Division was at 6%

~margins impacted due to high Aluminum cost and High logistic cost,EBITDA 9.4% but management feel with normal RM cost EBITDA may be around 13-15% in coming years.

~net debt 235 Cr

~capex this yr 55- 60 Cr

~capacity utilization 60-65% and in H2 it will be around 70-75%

~net debt 235 Cr

~capex this yr 55- 60 Cr

~capacity utilization 60-65% and in H2 it will be around 70-75%

~Alicon is now working with Tata motors in EV sector through TACO who are developing and supplying the battery packs and motors for EV platform to Tata Motors. .

-~ACL also been working with Dana Corporation on both domestic and international orders

-~ACL also been working with Dana Corporation on both domestic and international orders

~ACL is exclusive supplier for Ather Energy in India.

~content per vehicle with Ather for Alicon is around 17 kg (3% of Total Business from Ather)

~Total order booking now stands at around Rs. 3,150 crore over a period of 5 years

~content per vehicle with Ather for Alicon is around 17 kg (3% of Total Business from Ather)

~Total order booking now stands at around Rs. 3,150 crore over a period of 5 years

Risk -

- increase in Raw material cost

-Slow down in business segment.

- High working capital days ( Increasing since last few years)

- increase in Raw material cost

-Slow down in business segment.

- High working capital days ( Increasing since last few years)

• • •

Missing some Tweet in this thread? You can try to

force a refresh