Lunchtime update from the Grenfell Tower Inquiry:

Cavity barrier manufacturer says installation of barriers on Grenfell was "some of the worst I have ever seen"

Cavity barrier manufacturer says installation of barriers on Grenfell was "some of the worst I have ever seen"

Chris Mort carried out an examination of the way his product had been installed after the fire in 2018. Says he believes there were areas where the products either weren't fitted at all or stuck on with sillicone instead of fixed with a bracket

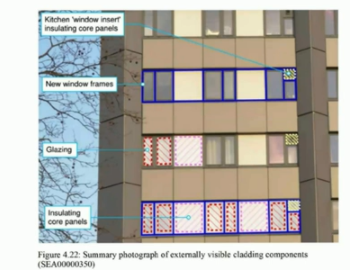

There were instances where gaps of 140mm were left, instead of the required 25mm - meaning the barrier would not have been able to close the gap. Brackets designed for horizontal barriers were used for the vertical, meaning they were pierced

"It was some of the worst I have ever seen," says Mr Mort asked for his view. "There's no grey area when it comes to inspection. It's either right or wrong... and if it's significantly wrong like these barriers were they would have to be removed and replaced."

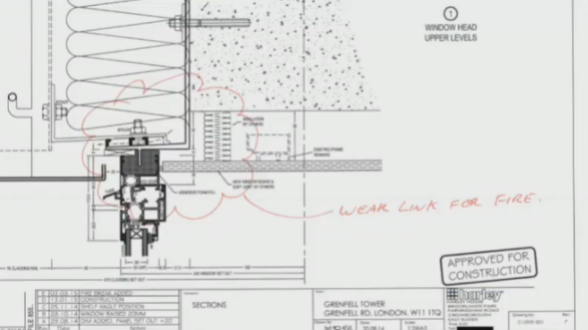

Earlier, was shown an email where he had noted on a diagram that there was a "weak link for fire" above windows where a cavity barrier should have been placed. This wasn't acted on by the design team.

Today Mr Mort said that the mistake in the drawings was a “clear error” and should have been picked up by “anyong in the senior project team”, including Harley Facades and building control - but said he didn't have any responsibility for the design

Also asked why he emailed suggesting his product for use on the project, given that it had never been tested in an ACM system. This was not Siderise responsibility, he says

“We were responding as to the suitability of the produce for use within a common construction environment"

“We were responding as to the suitability of the produce for use within a common construction environment"

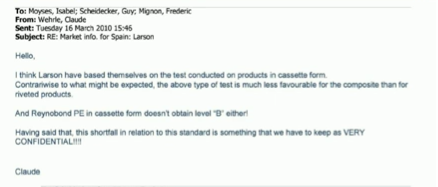

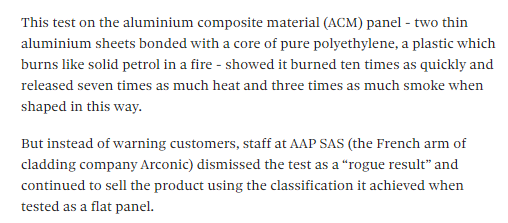

Shortly before lunch we've been hearing from Ricky Kay, who was a member of the marketing team seeking to grow its business. Will explain more about his evidence in my report at the end of the day.

• • •

Missing some Tweet in this thread? You can try to

force a refresh