Report from today at the Grenfell Tower Inquiry:

Senior manager at Arconic wrote an internal document in in 2007 pondering what its responsibility would be if a fire involving its product killed “60 or 70” people in a high rise

insidehousing.co.uk/news/grenfell-…

Senior manager at Arconic wrote an internal document in in 2007 pondering what its responsibility would be if a fire involving its product killed “60 or 70” people in a high rise

insidehousing.co.uk/news/grenfell-…

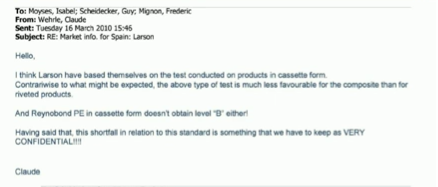

On this specific document, the marketing manager at Arconic (which later sold the cladding used on Grenfell Tower) went to Norway in 2007 for an industry get-together hosted by a Norwegian products distributor

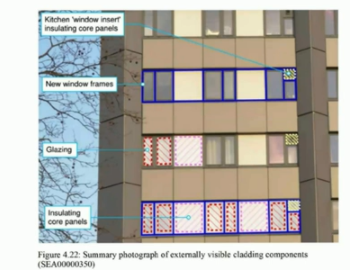

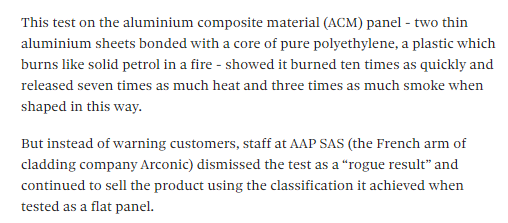

While there, attendees were invited to give presentations and a consultant from OTEFAL (a German metatls company) did a seminar on the dangers of using ACM as compared to solid aluminium.

The consultant (who was a bit of a part time journalist and actually planning a book on this stuff) said that using 5,000 sqm of ACM would add the same fuel content to a building as fixing an oil tanker with 19,000 litres of oil to its walls

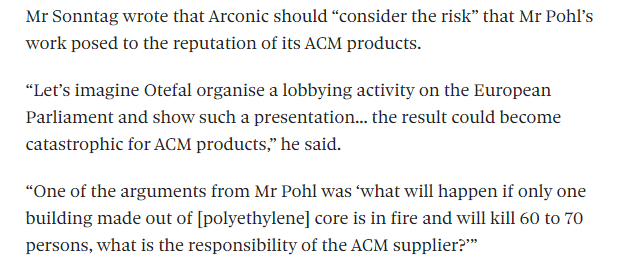

Mr Sonntag then writes an internal document fretting about what would happen if he presented this to the European Parliament. He says the following:

He says Arconic should consider switching to more fire retardant panels only. They of course don't and in 2017 the fire at Grenfell Tower, fitted with their cladding, kills 72 people

Today's evidence involved inquiry counsel Richard Millett going through the questions he would have asked witnesses who didn't attend. He presented probably more than 50 documents, all of which are interesting in their own right and a few of which (including this one) ...

... we hadn't seen before. Beyond the reach of a twitter thread to sum it all up but have covered some of it in the news article above and will have a bit more in our weekly round up on Friday.

• • •

Missing some Tweet in this thread? You can try to

force a refresh