As much as possible, I will try to be brief on this #Thread about starting a mini/cottage rice mill venture in Nigeria.

I will be discussing the processes involved in rice processing start-up nd the machines requirement and other successful business tips

Rice milling in Nigeria is a key component of rice production, rice paddy must be cleaned and milled before consumption. Milling makes the harvested rice palatable and attractive.

Rotimi Williams, an ambitious 37-year-old Nigerian entrepreneur and rice farmer,

Rotimi did not study agriculture in school. He was a former journalist and banker.

In his own words;

“I learned it all on Google. I downloaded every article I could find on rice production, consumed it and then practiced it on the field.”

1.Availability of Raw Material

2.Accessible Land space and Small warehouse for machines.

3.Machine Capacity Selection

4.Ensure adequate Water and Electricity supply

5. Storage planning

6.Utilization of by-products and wastes

In the SW, Ogun state, Ekiti, Kwara and some part in Lagos (Imota, Agbowa axis of Ikorodu) are strategic you can site your rice mills.

To produce quality rice,the following simple standard production procedures are required.

•Purchase of Paddy from the farmers

•Paddy Undergoes cleaning through Paddy Cleaner

•The Removal of unwanted part

•Rice goes through the Process of Whitening

•Packing of Raw Rice obtained from the above processes

•Sale to the End User

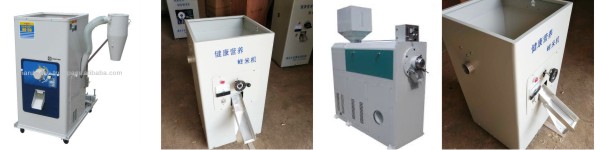

Depending on the size of rice processing plant, different types of milling machines are available according to their size and features. You may think of investing in a mini rice plant in the start of the business with a cost between 2-3 Million or less,,

The most important ones include pre-cleaning, husk removal, polishing and so on.

4.Other machines include Rice Polisher, Colour sorter, Rice whitener, Rotary sifter, weighing scales and Sack closer.

But dont forget I have quality Point of lay for sale.

Please come and buy. Ejoor oo