#AeroIndia2021 Thread.

When Airshows world over are getting cancelled, Aero India is going ahead with a shorter version focused on business side. I have no doubt, it is going to be a success with all the precautions and measures in place.

Though its not ideal this time for

When Airshows world over are getting cancelled, Aero India is going ahead with a shorter version focused on business side. I have no doubt, it is going to be a success with all the precautions and measures in place.

Though its not ideal this time for

non-biz visitors like me, I am looking forward to the virtual platform. It looks cool and I hope it will be continued for all the future events too. No Aero India Technical Seminars, which is a bummer though.

Anyway, let the show begin.

Anyway, let the show begin.

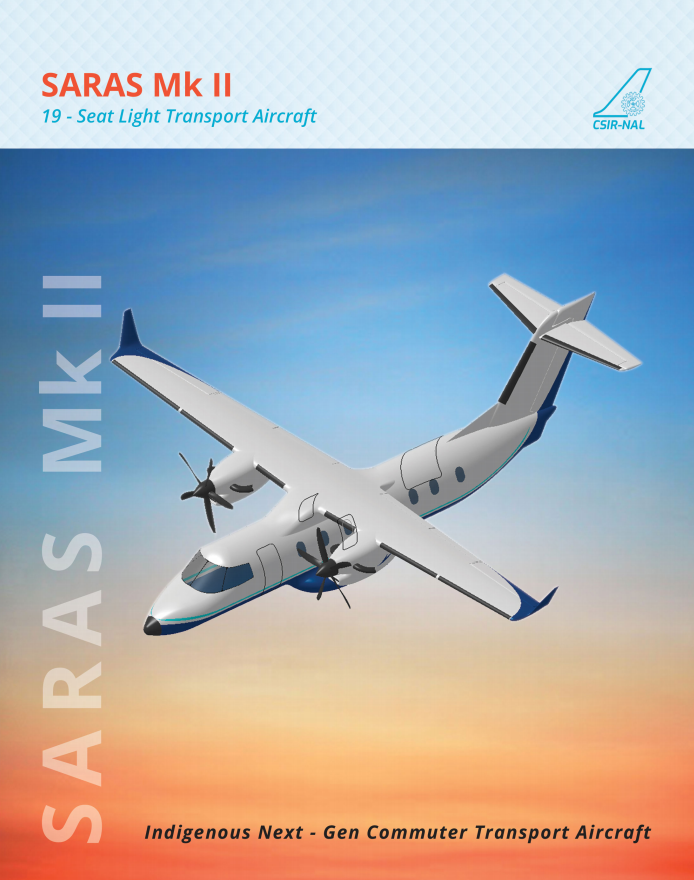

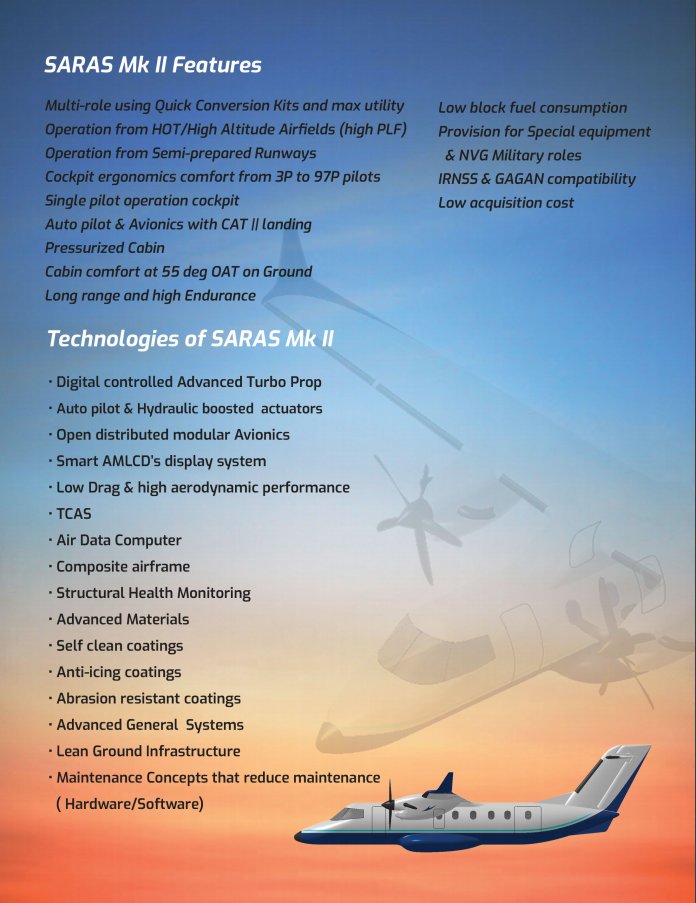

#SarasMK2 Brochure. Its looks like its embellished with all the bells and whistles. Its better than Do228 in practically every sense.

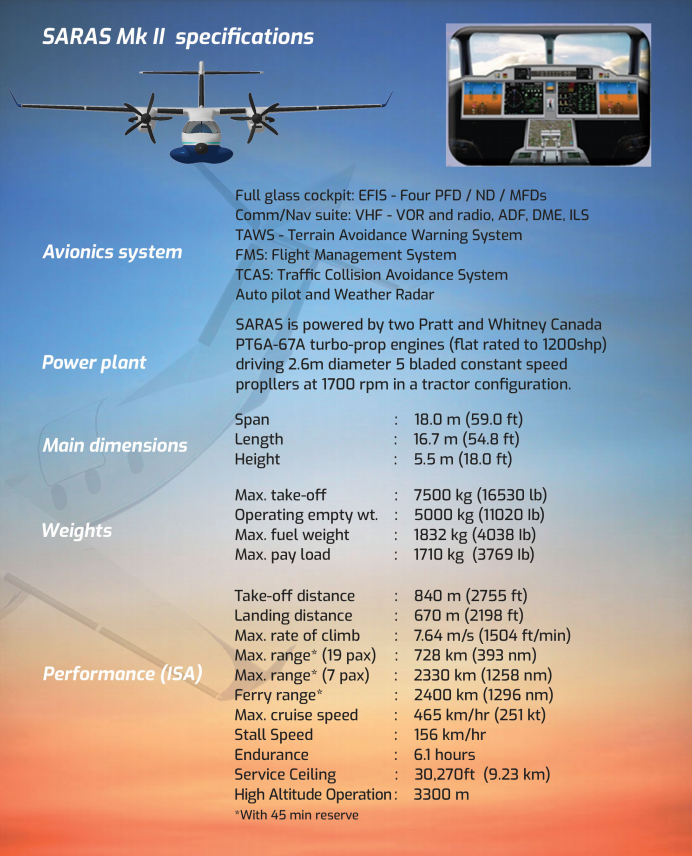

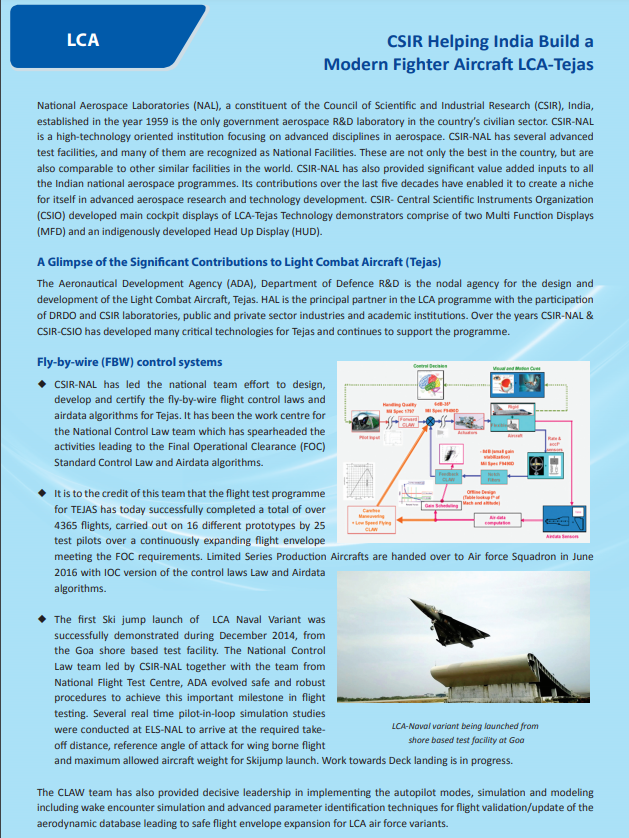

Glass cockpit meat for RTA70. Not sure if this mock up will be displayed in the #AeroIndia2021 or not.

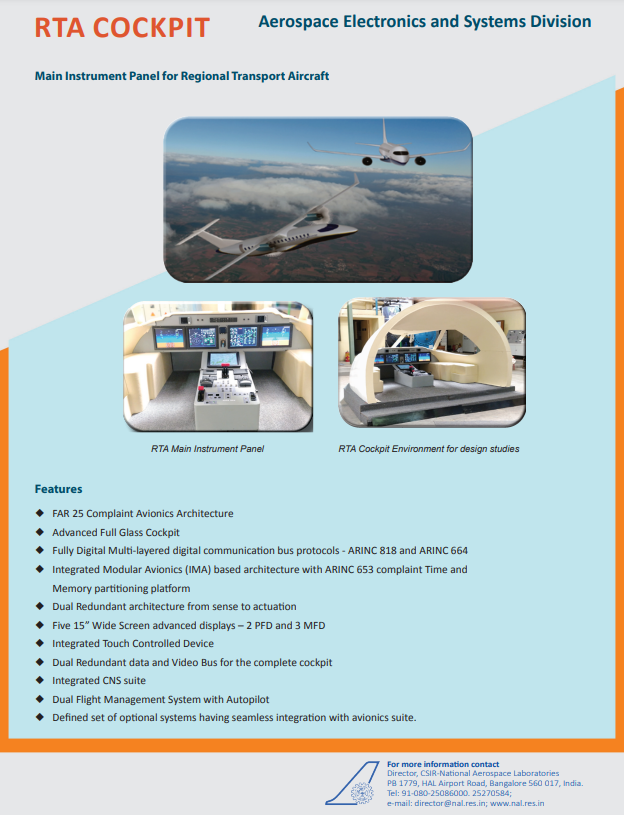

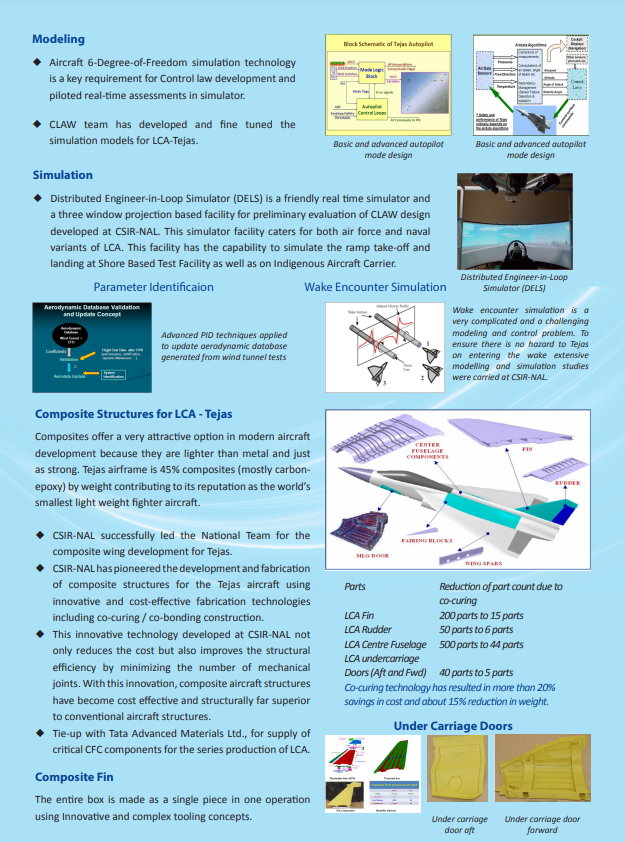

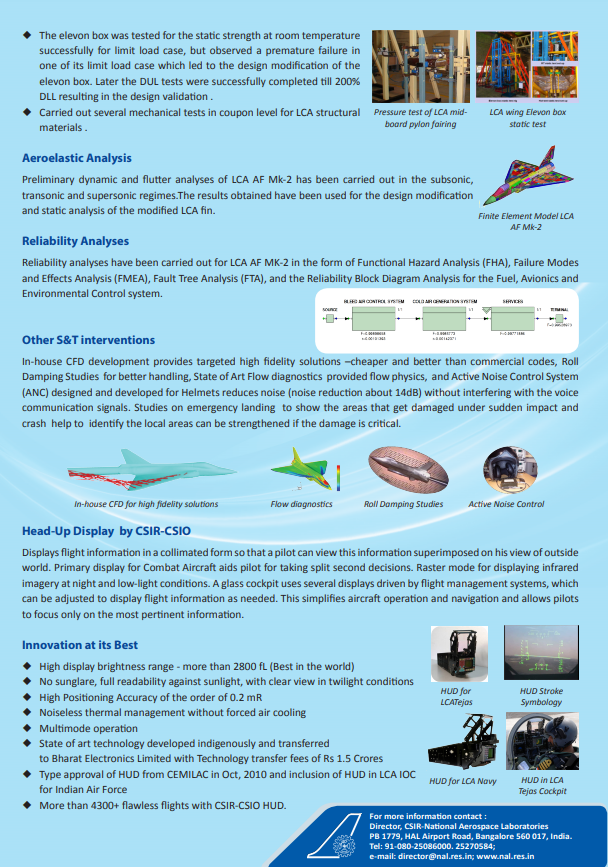

These 4 pages summarize NAL's contribution to the #LCA program. So much stuff in there. All those who wonder what was happening in LCA program for 30yrs, should study this in detail. And keep in mind that this is only one lab out of more than 100 work centers involved in LCA. All

the basic technology, design, development, testing, validation and manufacturing developed here over 3 decades form the bedrock on which the Indian Aviation sector is standing today. We had literally none of this existing in India in 80s. Everything is developed from scratch in

meagre funding and against all the odds. This is why LCA has taken a while. Now that we have all this know-how and most importantly the know-why at hand, we are pretty confident that the next iterations and programs can be completed in time bound manner without much technological

risk. Lets take the example of FBW FCS. The CLAW team developed the mathematical framework for the FCS of an unstable Fighter from scratch. They developed the 6-DoF simulation capabilities, Eng-in-loop, Pilot-in-loop, HW-in-loop and so on capabilities and facilities. The methods

and the best practices are well established and well validated by now. For Tejas Mk2, TEDBF, AMCA, all this is going to be used practically as it is with only incremental changes. Which means those programs do not have the lead time of 10-15yrs that is needed to develop all these

capabilities. What more, given the validation and finetuning from LCA Mk1 flight testing, all these tools and design best practices are matured enough to predict/create new systems for MWF or AMCA which are far more accurate and close to the reality in first iteration itself.

This is going to cut down the Design & Development time for the FCS and on the flight testing and certification.

For AMCA you dont anymore have to struggle to develop basic composite tech, only work on how to make the composites more stealthy by c-nanotube infusion or some other

For AMCA you dont anymore have to struggle to develop basic composite tech, only work on how to make the composites more stealthy by c-nanotube infusion or some other

means (which they have been working on in past decade). NAL already has developed technology right from Carbon fibre production to very advanced composite component manufacturing. The base is already there now, unlike in the 80s and 90s.

Now apply this for every single technology

Now apply this for every single technology

and component that is going in the future Fighters. Then you will understand where does the confidence that ADA displays today on timelines come from and why we can afford to aim for rather aggressive timelines for TEDBF, AMCA etc. Today we are more limited by funding than tech.

A poster on NAL's composite fibre making technology development. The technology was transferred to Kemrock which is now acquired by Reliance, AFAIK. Hope Reliance can scale is up to eliminate our import dependence. With their petrochemical and textile background, they are in a

unique position to aim for a global role in Carbon fibre production. And there is no dearth of capital as well. ;)

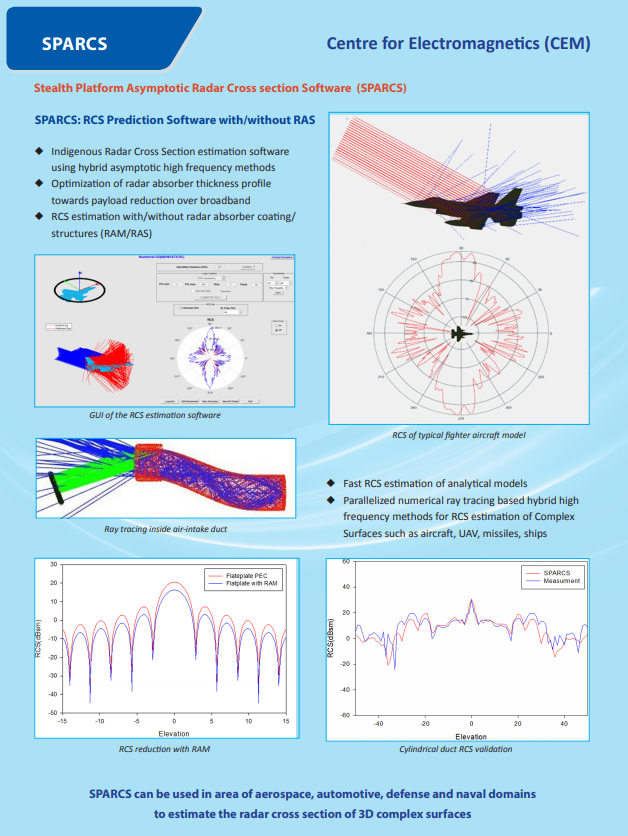

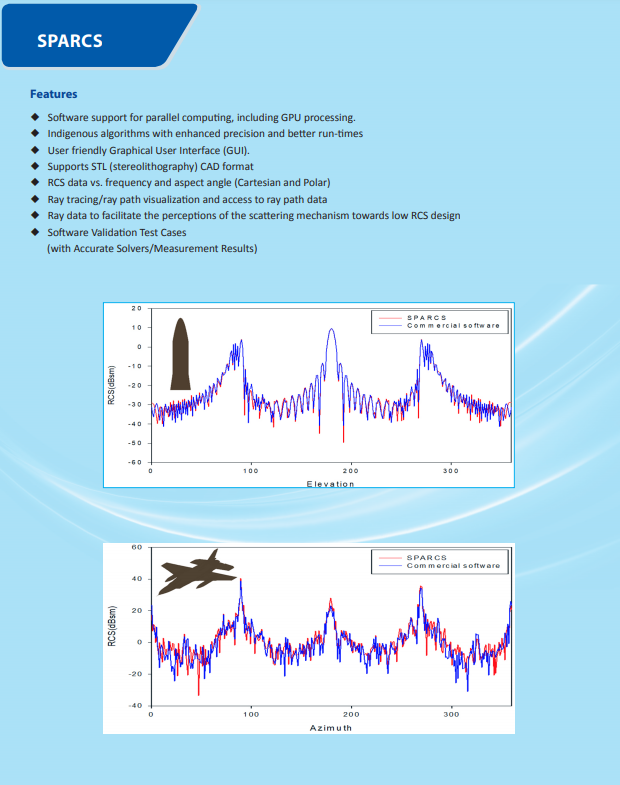

Our own desi RCS prediction SW - SPARCS - Stealth Platform Asymptotic Radar Cross Section Software, developed by NAL. We can see some examples simulated in the SW - F16, serpentine air intake and terminal stage of an ICBM.

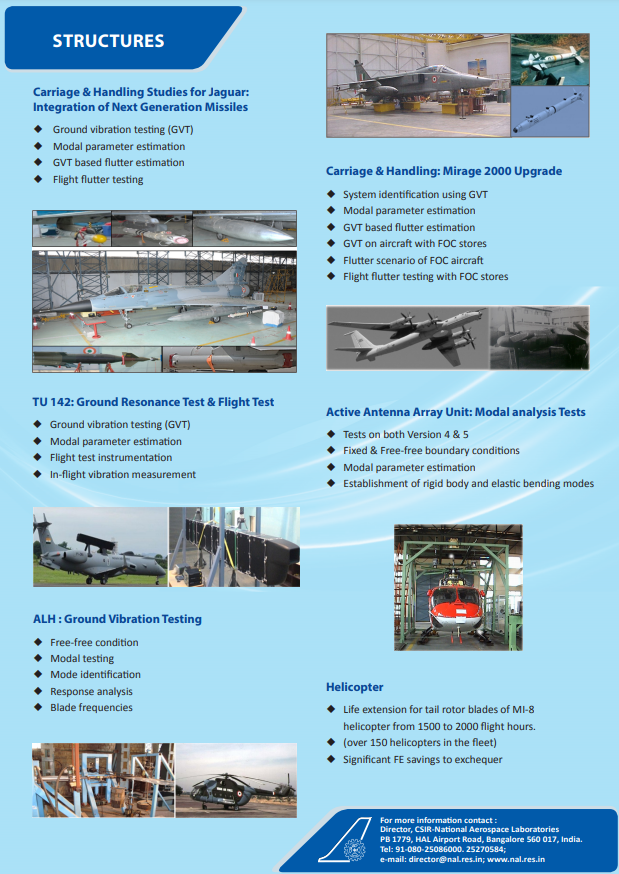

NAL's Structural test facilities and capabilities - Structural strength, fatigue life, ground vibration, in-flight vibration. mode identification, flutter, structural life extension and so on. NAL is the key agency in these capabilities.

This is interesting. NAL has developed a control carry case for local repair of composite panels of airframe or similar application.

A cool marketing video by Astra Microwave. They are supplying to practically every desi Radar/EW program.

A couple of AI ago, they were displaying RF seekers for BrahMos & AAM. Now I see a gimbled AESA seeker for missile under dev. @Firezstarter1

A couple of AI ago, they were displaying RF seekers for BrahMos & AAM. Now I see a gimbled AESA seeker for missile under dev. @Firezstarter1

@writetake has come up with this great series #InspiringADA. A brief but crisp update on ADA programs. Its good to see ADA folks talking in terms of program mile stones of PDR, CDR and so on. Its makes things crystal clear. I wish ADA (and indeed the entire @DRDO_India) could

maintains webpages on their sites which displays updated status of each of the publicly known programs in terms of the Program milestones like CR, CDR, PDR, FAI to precisely let the Citizens know about the status and expected timelines.

Here is the link to @writetake's #InspiringADA 4-part series thread. Do watch it. AKM's efforts to bring forth the "unsung heroes" in the limelight is commendable. Seeing the Team LCA even more enthusiastic than us jingo gives immense satisfaction.

https://twitter.com/writetake/status/1351568582224723968?s=20

And here is my rather long thread containing comments and highlighting the key points in the update.

https://twitter.com/nileshjrane/status/1351604444522110976?s=20

The complete #InspiringADA Series

Part-1A | bit.ly/3pc8nZK

Part-1B | bit.ly/3qBJZ45

Part-1C | bit.ly/3bYsXsG

Part-1D | bit.ly/2LUuXHV

Part-02 | bit.ly/2MiLxkL / AMCA

Part-03 | bit.ly/36abV7b / TEDBF

Part-1A | bit.ly/3pc8nZK

Part-1B | bit.ly/3qBJZ45

Part-1C | bit.ly/3bYsXsG

Part-1D | bit.ly/2LUuXHV

Part-02 | bit.ly/2MiLxkL / AMCA

Part-03 | bit.ly/36abV7b / TEDBF

Part-04 | bit.ly/3a4Hi4n / Young Scientists Forum (R-Day Special)

Part-05 | bit.ly/3qYu5Rk / #LCAAFMk2

Part-06 | bit.ly/3a8ZtGf / Virtual Reality

Part-07 | | NLCA Mk1

Part-05 | bit.ly/3qYu5Rk / #LCAAFMk2

Part-06 | bit.ly/3a8ZtGf / Virtual Reality

Part-07 | | NLCA Mk1

While ADA creates #TEDBF, NLCA MK1 will continue to provide invaluable flight testing experience and technology development for which will reduce the timelines for TEDBF significantly. For example, NLCA Mk1 already has certified all 350+ LRUs for landing

shock conditions (which is something which MiG29K was struggling with for quite a while even after induction). Any new/updated LRUs meant for TEDBF could be deck certified well in advance on NLCA Mk1 itself, cutting down the certification time for the same on TEDBF itself. Apart

from this NLCA, after proving the design capabilities, will now continue flight testing of the off-design conditions. The data coming from these tests will help optimize the TEDBF LG and Arrester hook design in the first iteration itself. Everything needed fr TEDBF could possibly

be tested on NLCA Mk1 a priori ahead of time. In addition, NLCA will continue the technology development. For example a immediate target is connecting the GE engine FADEC to the FCS so that the engine thrust could be controlled by the FCS directly without pilot inputs. Those who

are familiar with the deck landing would know how high the pilot load is with literally hundreds of pilots inputs on control stick and on the throttle are needed to maintain the desired glide path. With the engine controls plugged into the FCS, ADA can create an automated control

landing and take-off mode wherein the control stick inputs will be mapped to up-dow-left-right movement of the aircraft (rather than pitch, roll, yaw) and no throttle inputs needed at all. This is similar to the the "Magic Carpet" tech that is being developed for F/A-18. The next

step would be fully hands-off landing. NLCA already can TO in hands off mode, but for landing there needs to be an intelligent system which could predict the landing point wrt a moving deck and be able to guide the aircraft to that point. With this, NLCA could have a fully

automated and hands-off TO and Landing system (ATOL). This is expected to feed into TEDBF, Ghatak (UAV) and AMCA program (optionally manned tech). Without NLCA, we would have to wait min 7-8yrs before any of these prototypes are built, flight tested for IOC. But with NLCA, a

significant time is cut down on the Design and Development.

In fact this is the pattern for all technology and sub-systems developments now. We can derisk programs by running multiple parallel dev paths using LCA and NLCA, be is advanced FCS features, Radar, Avionics or stealth.

In fact this is the pattern for all technology and sub-systems developments now. We can derisk programs by running multiple parallel dev paths using LCA and NLCA, be is advanced FCS features, Radar, Avionics or stealth.

This part on ADA's Virtual Reality Lab is really cool. I am well aware of the capabilities of VR technologies and their applications in the industry. But for those who aren't, this is absolute cutting edge and the wide spectrum of application in ADA

quite exciting. ADA is usnig VR in practically every field imaginable, be it design and development (cockpit design, assembly design for ease of assembly and mfg), manufacturing (to develop efficient mfg sequences, processes to improve productivity), MRO (processes) and training

for mfg workforce as well as the MRO workforce. All this is going to not only cut down cycle time for various product development stages, it will improve the product support and training immensely. One example we can consider is that LCA Mk1 has maintainability related minor

shortcomings. With VR, such issues can be tackled at the preliminary design stage itself by running MFG and MRO processes in VR to see if existing design satisfies ease of manufacturing and maintenance or some adjustments need to be done. With VR, we can expect such issues would

not arise for future programs in any significant manner. In technical terms its called "Design for Manufacturability" and "Design for Maintainability".

The future prospects are even more exciting with Augmented Reality and Mixed Reality implementation on cards (Anyone remember

The future prospects are even more exciting with Augmented Reality and Mixed Reality implementation on cards (Anyone remember

the AR video from the PAKFA assembly line or the F35 assy line video where a GOM measurement is directly projected on a panel showing profile quality right at the assy stage..? We are gonna get there soon enough). In addition, gestural controls will also be developed to reduce

pilot work load in future. We see HAL is already working on the voice command capabilities.

Dont miss the cool snippets of retractable IFR of AMCA, engine installation process of LCA and some other interesting things.

Would be interesting to find out how much of this all is

Dont miss the cool snippets of retractable IFR of AMCA, engine installation process of LCA and some other interesting things.

Would be interesting to find out how much of this all is

ADA's own internal development in terms of the SW tech.

Can you see all this leading to something like the Digital Century Series of our own..??? Exciting possibilities. The next decade is crucial in so many ways.

Can you see all this leading to something like the Digital Century Series of our own..??? Exciting possibilities. The next decade is crucial in so many ways.

Next we have two videos of the LCA MFG assembly line in the Aircraft Division of @HALHQBLR. Even the team in HAL is rather charged up. A far cry from the days when HAL was accused of step-motherly treatment to LCA. Today they own MK1A.

Some interesting

Some interesting

snippets from Part 1.

First of all, what a gorgeous looking SP-23 in the background...!! Brilliant fit and finish. It rivals M2K easily.

HAL is ramping up from 8/yr to 16-20/yr production rate. For this, they are working on streamlining supply chain and reduce lead times in

First of all, what a gorgeous looking SP-23 in the background...!! Brilliant fit and finish. It rivals M2K easily.

HAL is ramping up from 8/yr to 16-20/yr production rate. For this, they are working on streamlining supply chain and reduce lead times in

every process, without compromising on the quality. (For those who are not familiar with MFG, ramping up of even a stable low-rate prod facility almost always throw a lot of quality issues. Its a non-trivial job to ramp up while maintaining required quality). HAL is focusing on

training, skill development, supplier development/consolidation, creating alternate vendor sources for module level sub-assy. As stated many time, HAL is looking forward to take up lead integrator road by outsourcing as much component and module level MFG as possible.

A juicy tidbit about the second line, HAL is looking to consolidate entire 2nd line at one location with 34000Sqm area in BLR. First phase of civil works is finished and the RM will inaugurate it on 2nd Feb 2021. New jigs and fixtures are being installed there. The facility is

expected to get fully functional by March 2022. What I am not quite clear about it whether this new facility is the 2nd line which was approved some time back by GOI and will the existing facility from the Aircraft devision will shift there or it will also be retained. Note that

LCA division already has a facility for 8/yr production, which is the original or the first line. May be @writetake could throw some light here.

The Part -2, a detailed look at the assy line situated at the Aircraft division, the oldest in HAL, the "Main Factory". This line is partially taking the load of MFG along with the line in LCA div. The Aircraft Div is rather experienced with good

exposure to the Western Fighter ToT programs.

- Aircraft Div line started as supplementary line to the LCA div. They equipped 5 aircrafts and made a few fuselage sections. But now the line is converted to a fully functional standalone assy line with capability to function

- Aircraft Div line started as supplementary line to the LCA div. They equipped 5 aircrafts and made a few fuselage sections. But now the line is converted to a fully functional standalone assy line with capability to function

independent of the LCA div. Now they have full set of all Fuselage jigs and two sets of Wing Jigs (the wings need much more time than fuselage assy (5 mnths), so the Aircraft div line has two set of wing jigs to expedite overall mfg).

- SP23 was the first fully made aircraft out

- SP23 was the first fully made aircraft out

of Aircraft Div. SP25 is expected to take two air very soon. The next in line are SP27, 29, 34, 35 in this FOC batch.

- The Aircraft Div is trying out a sort of "moving line" concept wherein they have split the equipping and final assembly stage which are done at different

- The Aircraft Div is trying out a sort of "moving line" concept wherein they have split the equipping and final assembly stage which are done at different

locations by specialised teams. I wonder what LCA division is doing. They were struggling with bottlenecks in the equipping stage earlier for which this alternative line was started.

- Its great to see a healthy competition within HAL between the Aircraft Div and the LCA Div.

- Its great to see a healthy competition within HAL between the Aircraft Div and the LCA Div.

The veteran div is bringing all its experience in improving things. So we have a young, dynamic div at one hand and an experienced div on the other competing for work-share for the MK1A order. Their experience with Hawk, Jags is allowing them to explore concepts like sub-assy to

reduce cycle time on the jigs, both at structural assy and equipping/final assy operations, rearranging assy sequence to streamline the process and reduce cycle time. Substantial improvements have been achieved in some cases. For ex, in one case, the cycle time was reduced from

15days needed for the LCA div to 3-4 days now.

- An online snag management system is created which collects data on all snags seen in the quality checks, filters frequent and critical snags and analyses them for root cause analysis and elimination. This must be very helpful in

- An online snag management system is created which collects data on all snags seen in the quality checks, filters frequent and critical snags and analyses them for root cause analysis and elimination. This must be very helpful in

ramping up while maintaining the quality.

- The pride seen in every single person working on Tejas is really something. (Similar pride is seen in the IAF teams working with Tejas as well). I don't see why such highly motivated team could not achieve the set targets.

- The pride seen in every single person working on Tejas is really something. (Similar pride is seen in the IAF teams working with Tejas as well). I don't see why such highly motivated team could not achieve the set targets.

The thread is getting too long. So splitting. Link to Part 2 -

https://twitter.com/nileshjrane/status/1355964416659841028?s=20

• • •

Missing some Tweet in this thread? You can try to

force a refresh