TESLA PRODUCTION SCHEDULING - 2021 Q2

With the latest reports from China we are able to update our view on Q2 Production Scheduling

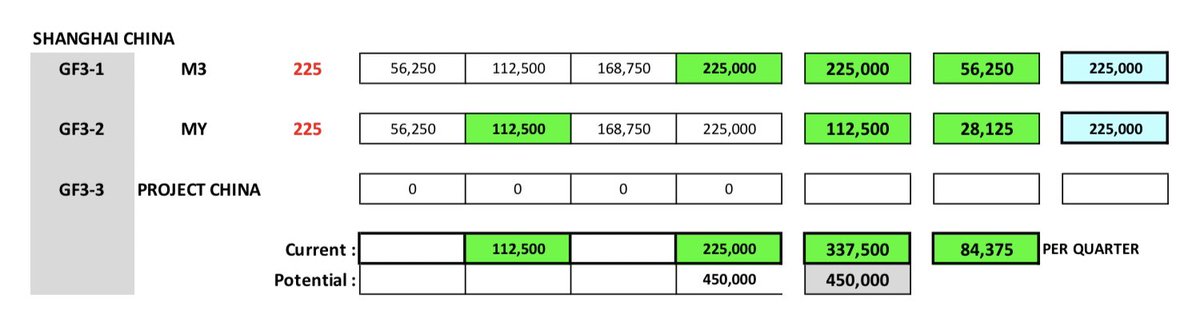

1. Line 1 is fully scheduled with 4 crews for 56,250 units per quarter or 18,750 units per month

- there is no room in the schedule for overtime

With the latest reports from China we are able to update our view on Q2 Production Scheduling

1. Line 1 is fully scheduled with 4 crews for 56,250 units per quarter or 18,750 units per month

- there is no room in the schedule for overtime

2. Line 2 is only 50% scheduled with 2 crews for 28,125 units per quarter or 9,375 units per month

- but this scheduling allows those crews to run overtime production

- but this scheduling allows those crews to run overtime production

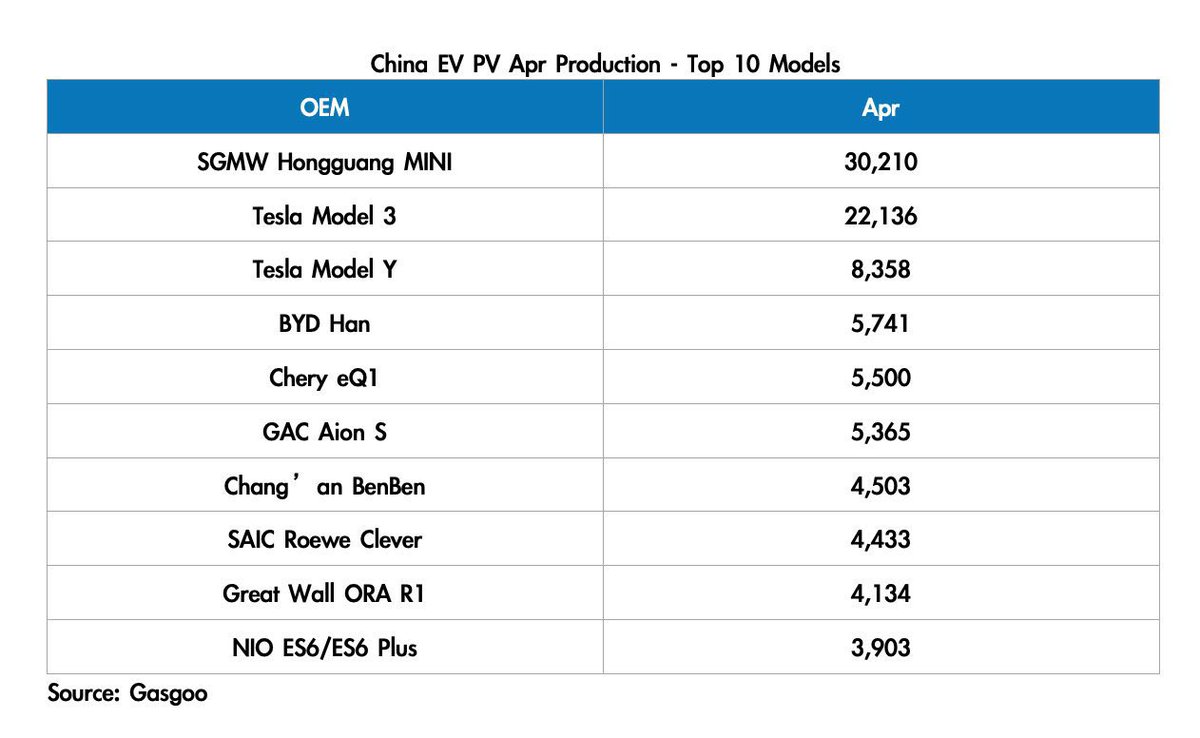

3. Line 2 appears to have been run with +20% overtime in APRIL by operating 6 days per week and 8 hours per day instead of 5 days per week and 8 hours per day

- the result was April production of 30,494 units as previously reported

- the result was April production of 30,494 units as previously reported

4. Line 2 appears to have been run with +50% overtime in MAY by operating 6 days per week and 10 hours per day instead of 5 days per week and 8 hours per day

- the result would be May production of about 18,750 + 9,375 x 150% = 32,813 units

- and 33,463 units were shipped

- the result would be May production of about 18,750 + 9,375 x 150% = 32,813 units

- and 33,463 units were shipped

5. If we assume the same operating mode for JUNE, then Line 2 would run with +50% overtime operating at 6 days per week and 10 hours per day instead of 5 days per week and 8 hours per day

- the result would be June production of about 18,750 + 9,375 x 150% = 32,813 units

- the result would be June production of about 18,750 + 9,375 x 150% = 32,813 units

6. So we may expect Q2 Production for Shanghai to be around 30,494 + 32,813 + 32,813 = 96,120 units

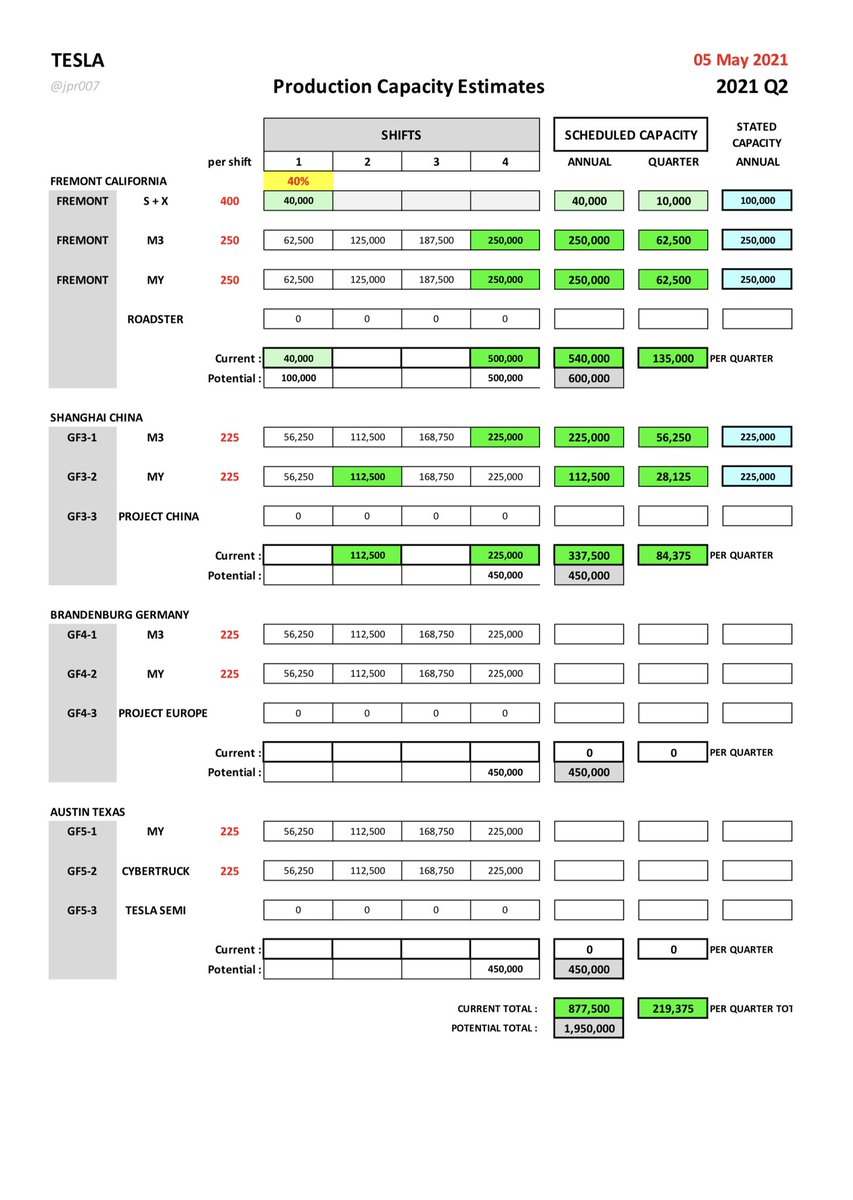

7. On that basis we are now looking at 135,000 units from Fremont + 96,120 units from Shanghai = 231,120 units

- up by +11,745 units or +5.4% from our 219,375 units baseline

7. On that basis we are now looking at 135,000 units from Fremont + 96,120 units from Shanghai = 231,120 units

- up by +11,745 units or +5.4% from our 219,375 units baseline

8. Note that our Q2 baseline still only contains 10,000 units for Model S

- but two quarters of Model S production can be up to 50,000 units

So we should be prepared for some upside surprises on the Model S number, depending on what has really been happening behind the scenes

- but two quarters of Model S production can be up to 50,000 units

So we should be prepared for some upside surprises on the Model S number, depending on what has really been happening behind the scenes

• • •

Missing some Tweet in this thread? You can try to

force a refresh