长春应化所自主研发的Cextrant230萃取剂实现规模化生产

ciac.ac.cn/xwzx/kyjz/2019…

2019-01-02

近日,长春应化所廖伍平团队自主研发的Cextrant230萃取剂成功实现了4立方米反应釜规模的生产。在国家973项目、中科院战略性先导科技专项、国家自然科学基金等项目的支持下,

ciac.ac.cn/xwzx/kyjz/2019…

2019-01-02

近日,长春应化所廖伍平团队自主研发的Cextrant230萃取剂成功实现了4立方米反应釜规模的生产。在国家973项目、中科院战略性先导科技专项、国家自然科学基金等项目的支持下,

廖伍平团队历时八年时间成功研发出以Cextrant230为代表的系列萃取剂,并将其应用于高丰度稀土元素铈和稀土伴生放射性元素钍以及过渡金属铜、锆、铪等的提取与分离,相关技术与工艺已获中国发明专利授权8项、美国和澳大利亚专利授权各1项,并入选“2015年中国稀土十大科技新闻”。

铈是稀土资源中的高丰度元素,特别是在我国北方稀土资源中,其含量达到稀土总量一半。此外,我国包头稀土矿和四川稀土矿中还伴生有大量放射性元素钍。因而,实现高丰度铈和放射性钍的优先分离是实现稀土资源绿色冶炼的重要措施与方案。但一直以来,受萃取剂性能与价格的制约,这一思路没有得到践行。

Cextrant230正是为满足这一需要而研发出来的廉价高效萃取剂,具有优先萃取分离四价铈、铈氟络离子和钍的优良性能,是自1993年以来唯一具有工业化应用前景的国产稀土萃取剂。2015年,廖伍平团队在四川江铜稀土有限公司完成了基于该萃取剂的氟碳铈矿清洁分离工艺扩大试验,

并于2015年6月18日在西昌通过了由稀土行业协会王晓铁副秘书长任组长的专家验收会,专家一致认为该工艺达到国际先进水平。该工艺的产业化将率先在四川江铜稀土有限公司进行。

Cextrant230萃取剂的规模化生产为基于该萃取剂的稀土分离新工艺的产业化提供了萃取剂保障,

Cextrant230萃取剂的规模化生产为基于该萃取剂的稀土分离新工艺的产业化提供了萃取剂保障,

将极大地推动新工艺在我国北方稀土资源包括包头稀土矿和四川稀土矿中的应用,助力我国保持在稀土冶炼工艺方面的领先地位。同时,该萃取剂的规模化生产也将极大推动其在其它金属矿产分离及工业废弃物回收方面的应用。

(稀土资源利用国家重点实验室、稀土及钍清洁分离工程技术中心)

(稀土资源利用国家重点实验室、稀土及钍清洁分离工程技术中心)

See

CC @StephenABoydPh1 @OskaArcher

https://twitter.com/ConradKnauer/status/950462461894774786for more info. Translation of the article to follow in this thread.

CC @StephenABoydPh1 @OskaArcher

The Cextrant230 extractant independently developed by Changchun Institute of Applied Chemistry realizes large-scale production [2019-01-02]

Recently, the Cextrant230 extractant independently developed by Liao Wuping's team of Changchun Institute of Applied Chemistry has

Recently, the Cextrant230 extractant independently developed by Liao Wuping's team of Changchun Institute of Applied Chemistry has

successfully realized the production of 4 cubic meters reactor scale. With the support of the National 973 Project, the Strategic Leading Science and Technology Project of the Chinese Academy of Sciences, and the National Natural Science Foundation of China, the team of

Liao Wuping successfully developed a series of extractants represented by Cextrant230 and applied them to high abundance in eight years. The extraction and separation of rare earth element cerium and rare earth associated radioactive elements thorium and transition metals such as

copper, zirconium, hafnium, etc. The relevant technologies and processes have been granted 8 invention patents in China and 1 patent in the United States and Australia, and were selected as "2015 Top Ten Science and Technology News of China's Rare Earth".

Cerium is a highly abundant element in rare earth resources, especially in the rare earth resources of northern my country, its content reaches half of the total rare earth resources. In addition, a large amount of radioactive element thorium is also associated with rare earth

mines in Baotou and Sichuan. Therefore, realizing the preferential separation of high-abundance cerium and radioactive thorium is an important measure and plan to realize the green smelting of rare earth resources. However, due to the constraints of the performance and price of

the extractant, this idea has not been implemented. Cextrant230 is a cheap and efficient extractant developed to meet this need. It has the excellent performance of preferentially extracting and separating tetravalent cerium, cerium fluoride ion and thorium.

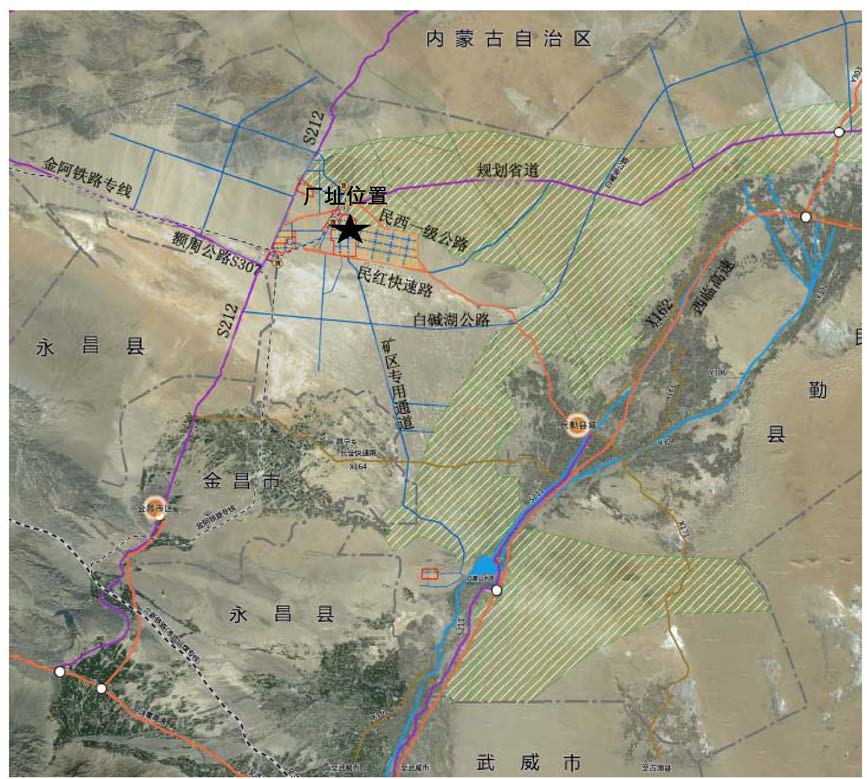

It is the only domestic rare earth extractant with industrial application prospects since 1993. . In 2015, Liao Wuping’s team completed the expanded test of the bastnaesite clean separation process based on the extractant in Sichuan Jiangtong Rare Earth Co., Ltd., and

passed the test by Wang Xiaotie, Deputy Secretary of the Rare Earth Industry Association in Xichang on June 18, 2015. At the expert acceptance meeting of the leader of the team, the experts agreed that the process reached the international advanced level.

The industrialization of this process will take the lead in Sichuan Jiangtong Rare Earth Co., Ltd.

The large-scale production of Cextrant230 extractant provides an extractant guarantee for the industrialization of a new rare earth separation process based on the extractant,

The large-scale production of Cextrant230 extractant provides an extractant guarantee for the industrialization of a new rare earth separation process based on the extractant,

which will greatly promote the application of the new process in rare earth resources in northern my country, including Baotou rare earth mines and Sichuan rare earth mines. my country maintains its leading position in rare earth smelting technology. At the same time,

the large-scale production of the extractant will also greatly promote its application in the separation of other metal minerals and industrial waste recovery.

(State Key Laboratory of Rare Earth Resources Utilization, Rare Earth and Thorium Clean Separation Engineering Technology Center)

[Translation by Google]

[Translation by Google]

• • •

Missing some Tweet in this thread? You can try to

force a refresh