Update from this morning at the Grenfell Tower Inquiry:

- Former resident Lee Chapman describes efforts to complain about gas pipe installation in tower's communal staircase

- Former resident Lee Chapman describes efforts to complain about gas pipe installation in tower's communal staircase

So this morning we've heard from the first resident witness from this part of the inquiry, Lee Chapman - former secretary of the Grenfell Tower Leaseholders Association. He lived on the 22nd floor with his partner Naomi Li.

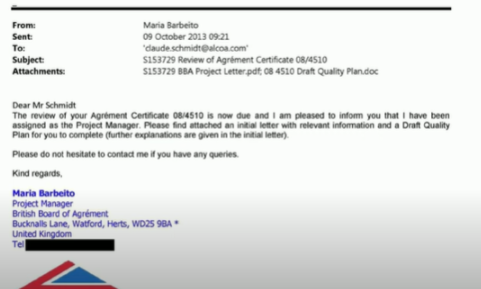

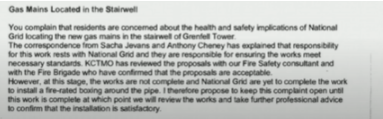

Primarily, his evidence focused on GTLA's complaints about work from 2016 onwards to install new gas pipes through the tower's staircase. This work was carried out by the National Grid and was separate to the refurbishment of the tower by Rydon et al

He learned about the works when he saw workers drilling holes through concrete to fit the pipes - and he was immediately worried about 'boxing in' to protect the pipes, something he felt had been done poorly for the recently installed communal hot water pipes.

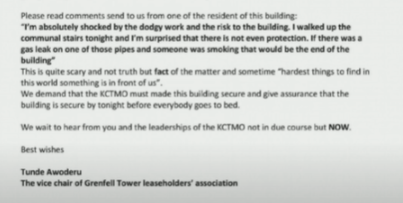

GTLA picked this up in March 2017, calling for an independent inspector to check that the works being carried out were safe. Vice chair Tunde Awoderu's email contained a warning that "if there was a gas leak and someone was smoking... that would be the end of the building"

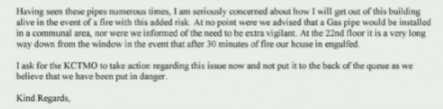

Mr Chapman followed this with emails to Millicent Williams, estate manager, writing to tell her: "I am seriously concerned about how I will get out of this building alive in the event of a fire with this added risk". Further emails sent to other TMO/RBKC managers through March.

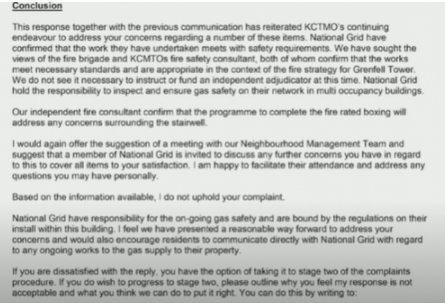

The complaint is dealt with by TMO's Anthony Cheyne at stage one, and a response sent on 5 May 2017. Declines to put independent adjudicator in place, saying TMO has liased with fire brigade and its independent fire consultant (Carl Stokes) on the matter

GTLA follow up, escalating complaint to stage two and asking for copies of reports. They did not receive them. On 6 June, Peter Maddison of KCTMO responds. Says works are responsibility of National Grid, but as works are not complete will seek professional assurance when they are

Conclusion of Phase 1 was impact of gas in fire "appears to have been minimal", although flames did not stop until supply was shut off. Moore-Bick did say "works associated with the installation of the new gas riser were incomplete and may have contributed to the spread of smoke"

Mr Chapman also gives evidence about the replacement of his flat door, which the couple did themselves in 2016. Says they were told by TMO it needed to have 30 minutes fire resistance which he ensured it did but not that it needed a self-closer. Also says...

... no one from the TMO came to check it following installation. After lunch we will hear from David Collins, who was chair of the residents group (known as 'the compact') during the main refurbishment.

• • •

Missing some Tweet in this thread? You can try to

force a refresh