Imagine that you design the perfect cake. Due to the combination of different layers of ingredients, it will have awesome unrealistic properties. A #meta cake!

But: will the structure withstand the temperatures needed during baking?

Thread on my paper 👇

onlinelibrary.wiley.com/doi/10.1002/ad…

But: will the structure withstand the temperatures needed during baking?

Thread on my paper 👇

onlinelibrary.wiley.com/doi/10.1002/ad…

Instead of a cake, we designed a near-perfect absorber.

Less than 0.1% of the light hitting it can escape it!

How is that possible? By disorder!

Turns out that having the layers of ingredients intermix a bit makes an even better cake!

Less than 0.1% of the light hitting it can escape it!

How is that possible? By disorder!

Turns out that having the layers of ingredients intermix a bit makes an even better cake!

https://twitter.com/RealSci_Nano/status/1588599430109794304?s=20&t=jSoKGRZHgdK004tyQiPraA

1st lesson: it's not always worth it to find a fabrication technique that avoids intermixing.

Those techniques are way slower and don't necessarily improve their properties.

A step towards scalable, large-area #metamaterials.

Those techniques are way slower and don't necessarily improve their properties.

A step towards scalable, large-area #metamaterials.

https://twitter.com/RealSci_Nano/status/1587850498723532801?s=20&t=t9w4Tr0ovaClngfiV4z5DQ

A material with such a high absorption would be great for solar energy solutions such as thermophotovoltaics... if it would withstand high temperatures.

That's why the next step was to put it in the oven at different temperatures.

That's why the next step was to put it in the oven at different temperatures.

https://twitter.com/RealSci_Nano/status/1588123349372248064?s=20&t=DqfXff8Ajzz_5o3am3WWCg

High temperatures mean different things to different communities. In metallurgy, we typically compare the "homologous temperature", which is the temperature divided by the melting point of the material.

Everything above 30% of the homologous T is considered high temperature.

Everything above 30% of the homologous T is considered high temperature.

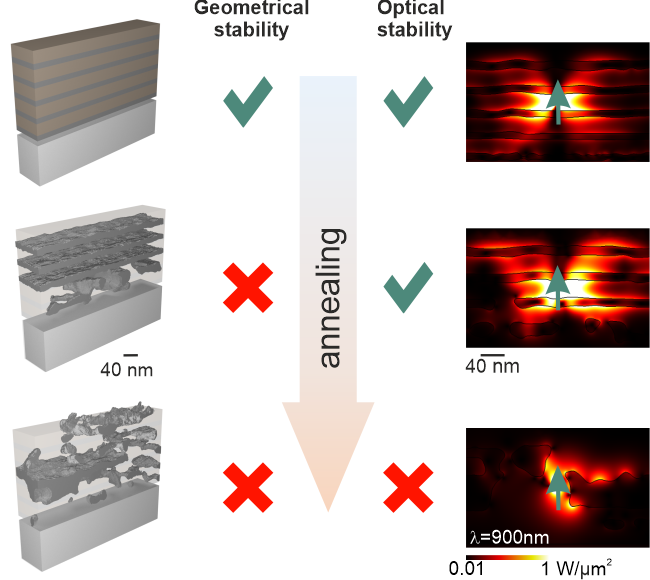

Turns out that our metamaterial still has awesome properties at almost 50% of its melting point, very very hot!

However, when we cut the cake baked at that temperature and look at its structure, the lower layers are gone without affecting its properties.

However, when we cut the cake baked at that temperature and look at its structure, the lower layers are gone without affecting its properties.

And when I say "cut and look", that is exactly what we do.

This tweet plays with that concept, exemplifying what we do with a focussed ion beam (FIB) and an electron microscope (SEM) at smaller scales:

This tweet plays with that concept, exemplifying what we do with a focussed ion beam (FIB) and an electron microscope (SEM) at smaller scales:

https://twitter.com/hexallography/status/1559224547613839365?s=20&t=7dnWv5-hYqS1bFU6wkhhHA

So our cake still has its abnormally cool optical properties at high temperatures, even though the structure has began to degrade.

How is that possible?

Yet another prove that disorder isn't necessarily a bad thing!

How is that possible?

Yet another prove that disorder isn't necessarily a bad thing!

https://twitter.com/RealSci_Nano/status/1589258115236605953?t=5yzOJcYkrxxVlKTj-BlQaw&s=19

The structure of the cake only degrades in the lower layers in this regime. The upper layers are untouched!

We know because we cut alternated cutting a bit more of the cake with taking pictures, and reconstructed all the images in a #3D tomography!

We know because we cut alternated cutting a bit more of the cake with taking pictures, and reconstructed all the images in a #3D tomography!

So, why does the cake start breaking at the bottom? Understanding that could help us identify why the degradation is happening and what is driving it.

We did simulations on our 3D structures to find out, and we compared how important the different driving forces are.

We did simulations on our 3D structures to find out, and we compared how important the different driving forces are.

There are basically three reasons for degradation :

1 dissolve in each other (not here)

2 move to try to minimize the area of one element that is in contact with the other

3 move to minimize how stressed they are.

Most literature focusses on 2, but we find that 3 is dominating!

1 dissolve in each other (not here)

2 move to try to minimize the area of one element that is in contact with the other

3 move to minimize how stressed they are.

Most literature focusses on 2, but we find that 3 is dominating!

The cherry on top of the cake is to confirm this experimentally: if we change the stacking order, we can change where the instability starts: now it starts on the top cos a different force dominates.

And top of that, the evaporation temperature also changes! Double cherry!

And top of that, the evaporation temperature also changes! Double cherry!

To find out more about what metamaterials can teach us about baking...

onlinelibrary.wiley.com/doi/10.1002/ad…

onlinelibrary.wiley.com/doi/10.1002/ad…

https://twitter.com/LNM_eth/status/1582746785528700928?s=20&t=DqfXff8Ajzz_5o3am3WWCg

This is not the sweetest research carried out in our lab recently though!

aip.scitation.org/doi/abs/10.106…

ethz.ch/en/news-and-ev…

aip.scitation.org/doi/abs/10.106…

ethz.ch/en/news-and-ev…

• • •

Missing some Tweet in this thread? You can try to

force a refresh