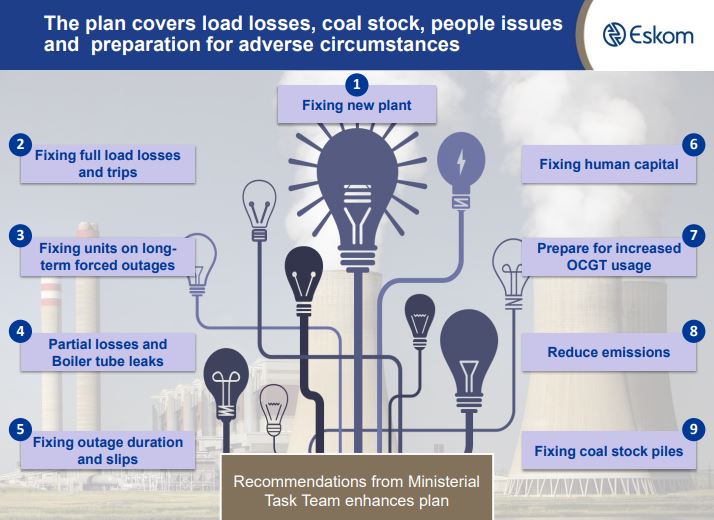

1. The main coal conveyor feeding coal from Grootegeluk faied with belt and structural damage.

2. Protection devices on the main coal conveyor failed to detect the fault timeously.

... (cont)

3. The stacker/reclaimers at the Medupi coal stockyard are not working, this the coal stockyard is bypassed.

4. Coal was been transported by truck from the stockyard to the boiler bunkers causing massive congestion and reducing output of the generators.

... (cont)

4. The coal mills are of wrong design, causing excessive wear & tear, & increased maintenance & downtime.

5. The design height of the boilers is inadequate (too low), causing excessive temperatures within the boiler & flue gas.

,...(cont)

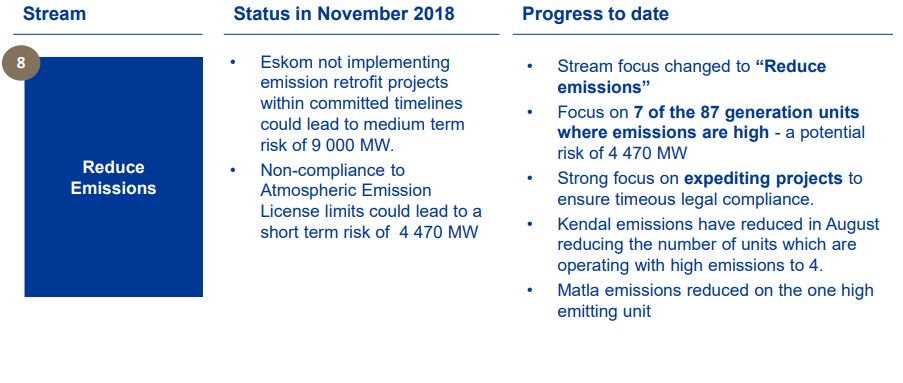

6. Excessive flue gas temperature is causing premature failure of the pulse-jet fabric filters (an essential fly ash collection & pollution control system).

7. The ash handling system is unable to cope with the volume of bottom ash & fly ash from the boilers.

(ends)