Iron & steel were once shrouded in myth. Now they are everywhere around us.

If someone from ancient times were brought to the present, our abundance of high-quality metal would make them think we were gods.

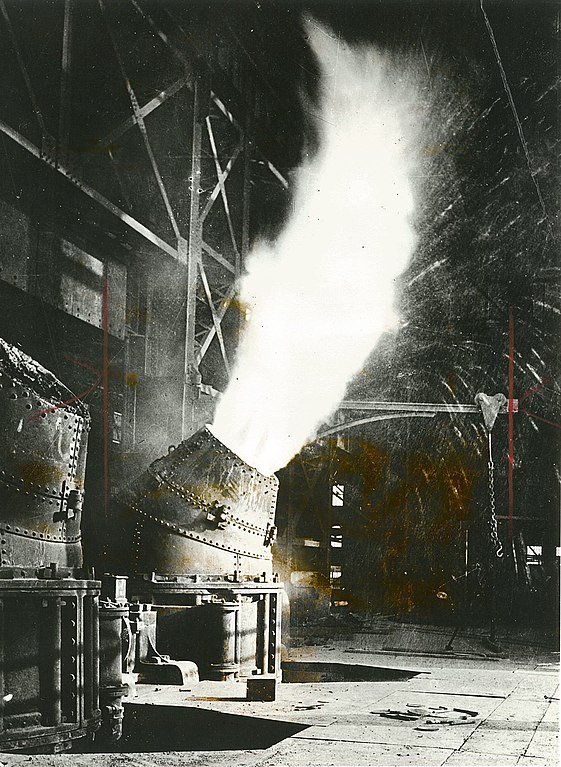

How did this happen?

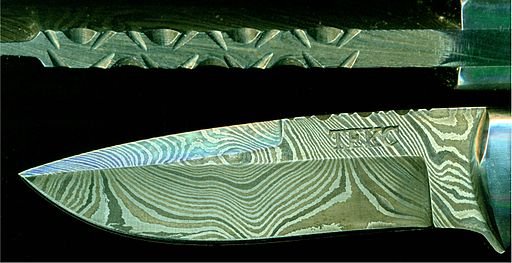

Ancient blacksmiths found that heating the iron again in charcoal will harden the outside, good for a cutting edge. Steel is basically this hardened form of iron.

But this form of iron cannot be worked, like wrought iron. It is brittle, and breaks when hammered. A nuisance, thrown back to be remelted.

Was something getting into the metal to harden it, or being removed? And if there was a foreign substance, what was it?