Imagine looking at some wood and metal, just sitting there on the ground all formless, and thinking: I can make a thing of both utility and beauty out of this.

Here’s a thread about how they do that. #MusTools

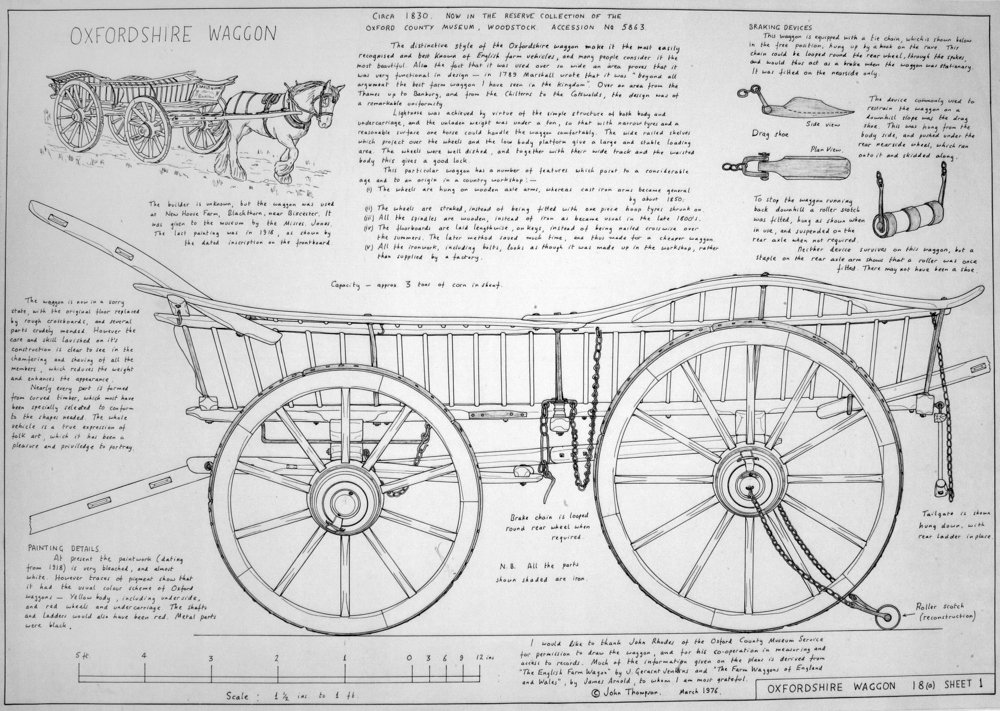

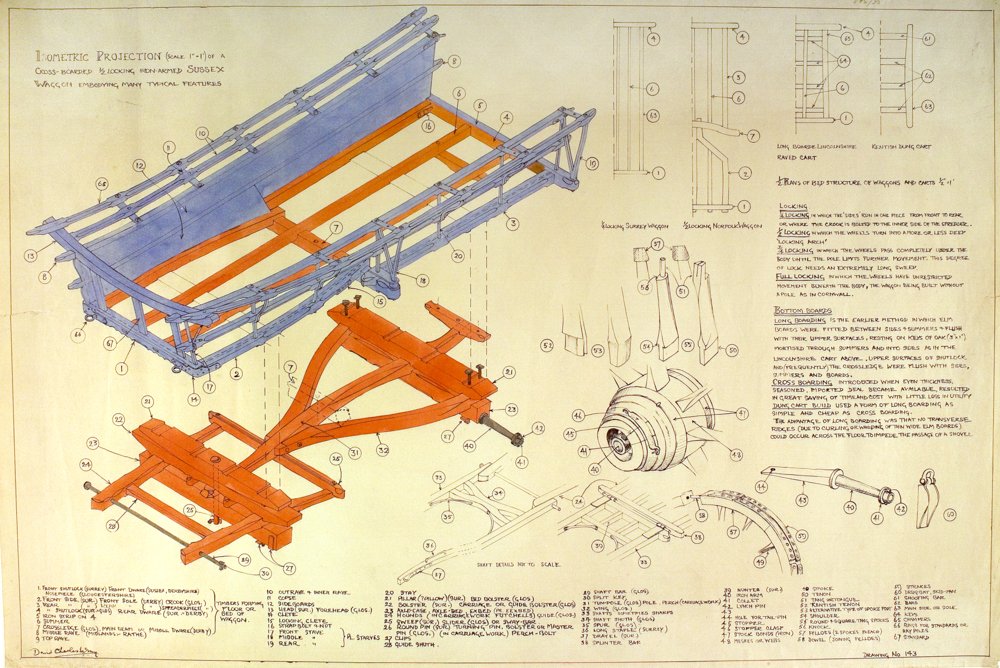

Before the combustion engine and pneumatic tyres, vehicles relied on their construction and draught animals to be able to get around.

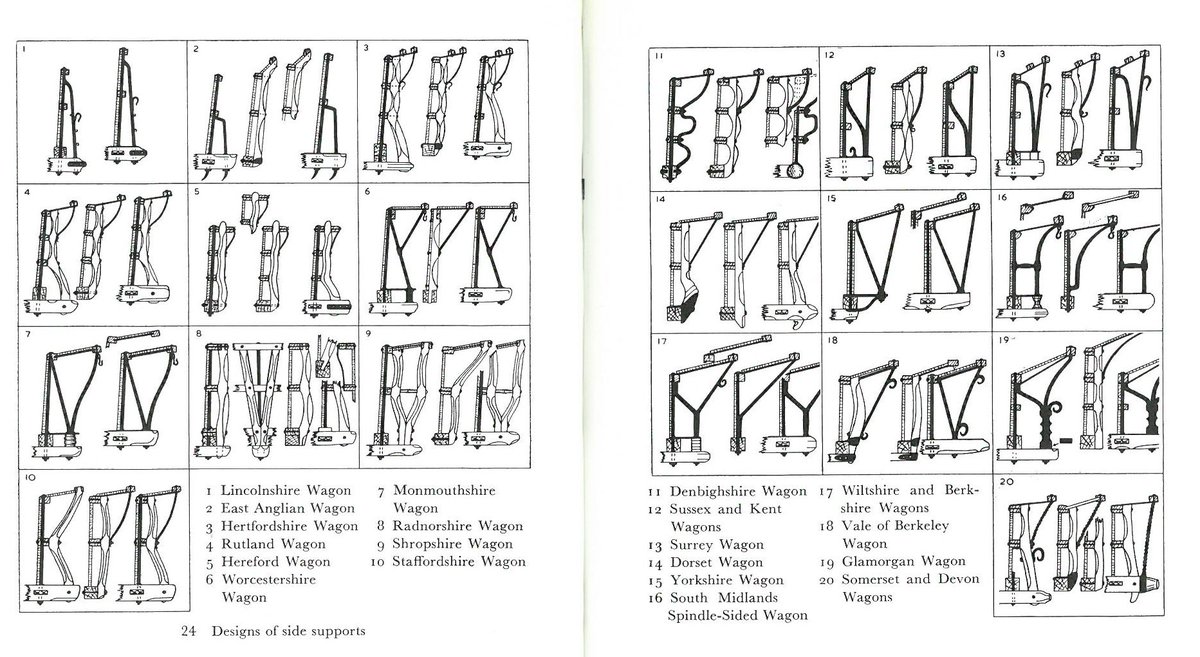

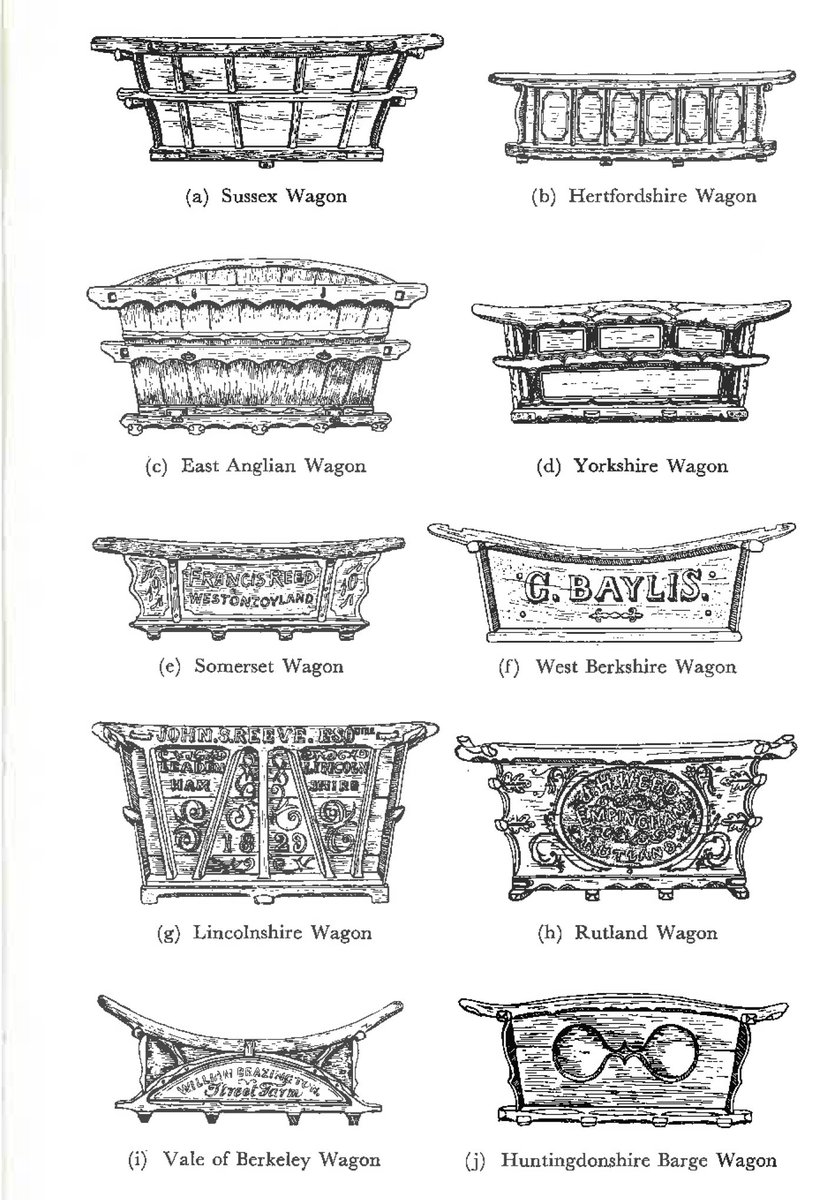

Each wagon is a distillation of its region’s geography. Each is uniquely suited to its environment.

#MusTools

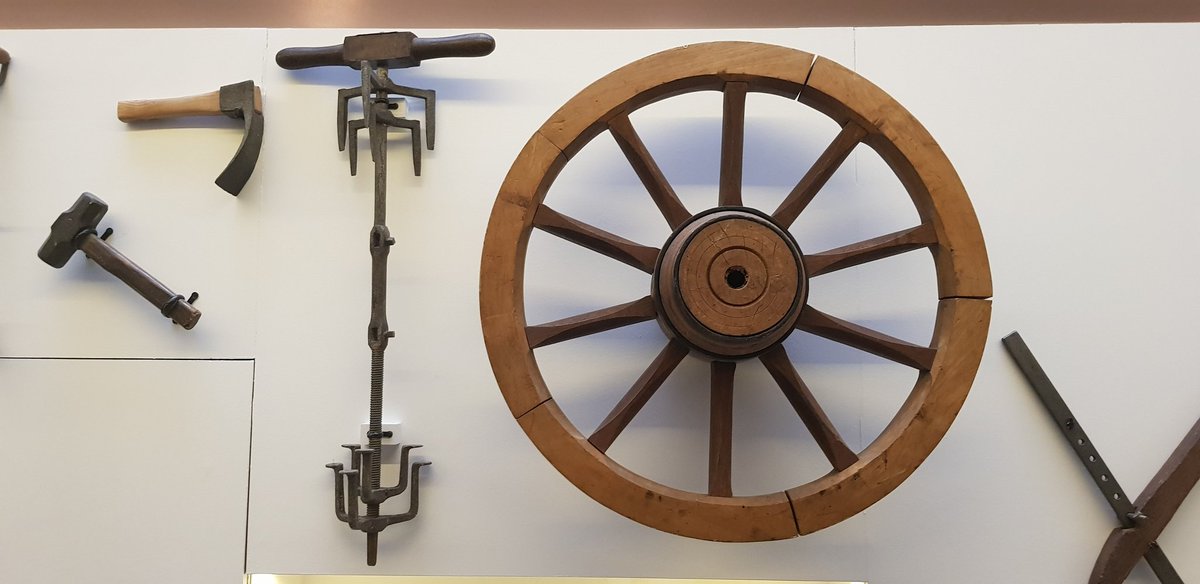

Craftspeople use roughly 80-90 different tools to make one.

This includes sawing the wood, crafting the wheel, forging the ironwork, tyring the wheels and painting the body.

#MusTools

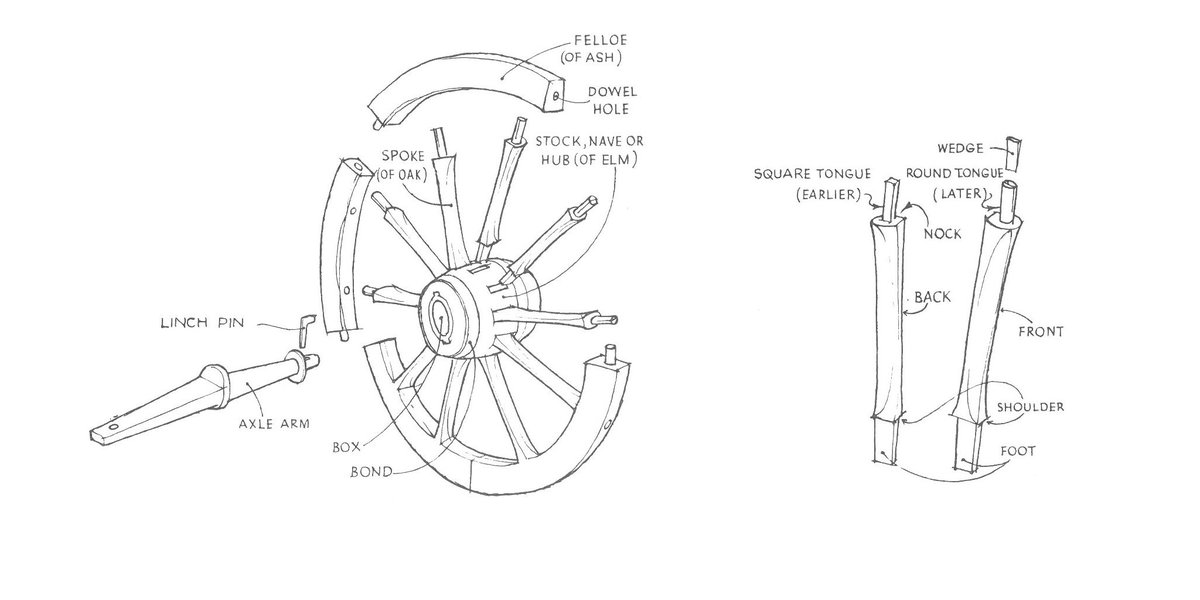

You saw lengths of elm logs, then you leave them on a shelf for a few years.

Seriously. Just let them chill and season. For years.

#SeasonAndChill #MusTools

#MusTools

#MusTools

Making spokes is REALLY simple:

•find well-seasoned oak

•cleave it

•shape with an axe (it’s okay to be rough)

•trim it with a drawing knife or spokeshave

•a bit of tenoning to make a tongue at the end to fit the hole in the hub

#Simple #MusTools

These are the bits which form the wheel's circular shape.

#MusTools

You lay your sweet wheel down and then tap the felloes onto the spokes, and then draw them together using the spoke dog and a big mallet.

#MusTools

Up until the 20th century a popular method of tyring was to nail bands of metal called strakes to the wood. Afterwards, hooped iron tyres were preferred.

#MusTools

It’s then put onto the wheel while hot using tyre dogs, and quickly submerged in water to make the metal contract onto the wheel.

#MusTools

Beech or ash was used for the axle, though iron was common later. It was cut according to a frame, then shaped with a drawknife or spokeshave.

#MusTools

You could have panels, spindles or planks depending on where in the country or which wainwright you had. The iron supports were entirely down to the blacksmith.

#MusTools

They require precision and skill, but also tradition to bring them alive. We love wagons.

#MusTools