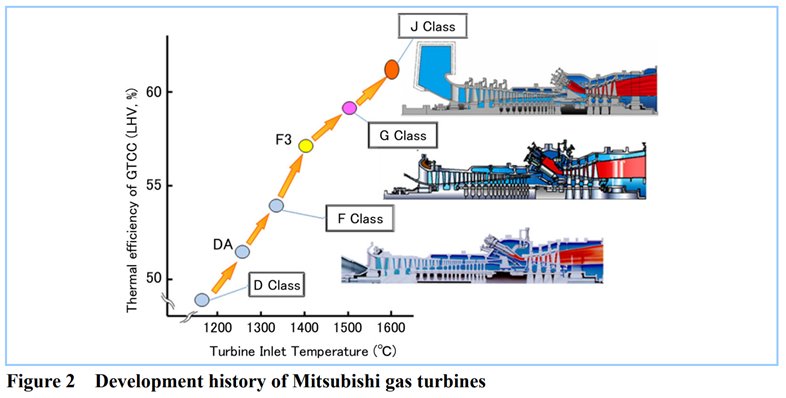

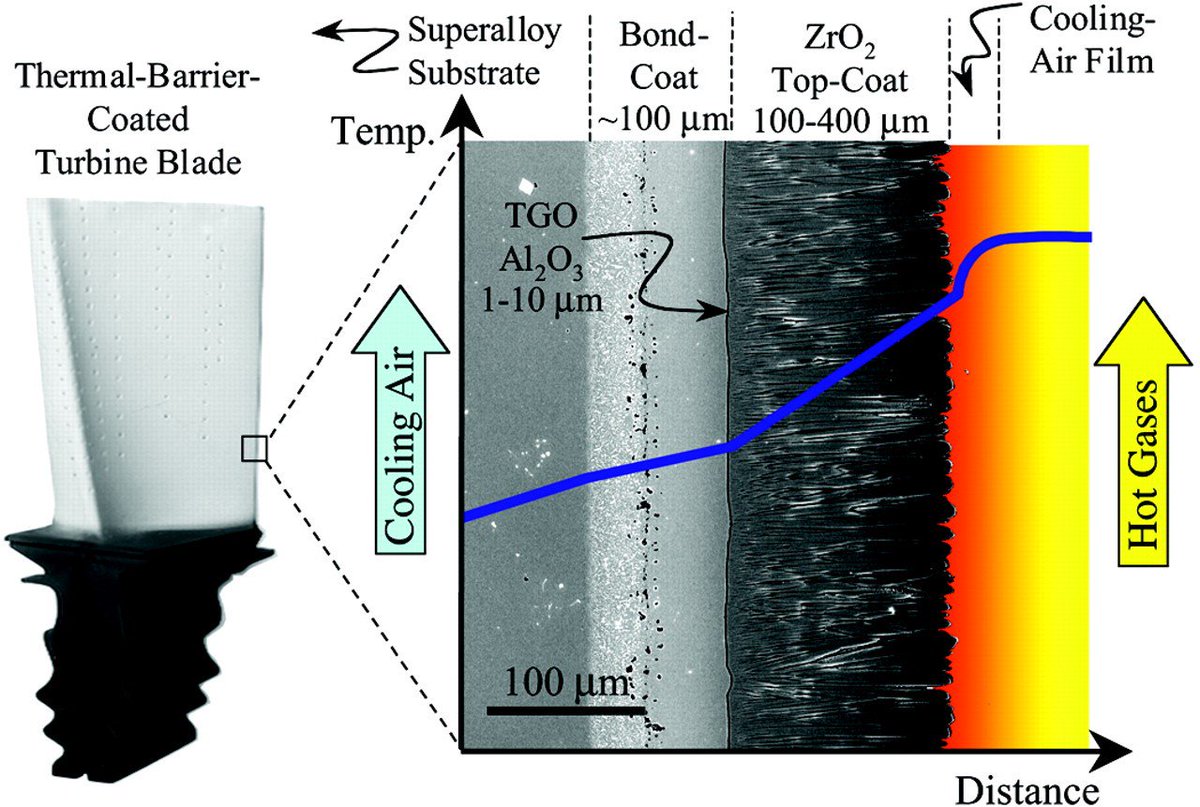

1) Electricity Generation (The most efficient gas turbine in the world is made by GE. The 9HA: ge.com/power/gas/gas-…), &

2) Propulsion (e.g. jet engines on airplanes: animagraffs.com/inside-a-jet-e…).

(an area with more than 22 million people).

If you want the details, check out equations 2.22, 2.31 & 2.42 here: web.stanford.edu/~cantwell/AA28…

And: ocw.mit.edu/ans7870/16/16.…

1 – (Exhaust Temperature / Turbine Inlet Temperature).

For details see here: web.stanford.edu/~cantwell/AA28…

Or here: web.mit.edu/16.unified/www…

i.pinimg.com/originals/27/d…

link.springer.com/article/10.136…

researchgate.net/figure/Variati…

mhi.co.jp/technology/rev…