Last week was discovery week,I and other media influencers around Uganda were taken on a #PAUOilVisit around the Albertine Graben.

Ladies and gentlemen, allow me take you through the Uganda|Tilenga Project.

Project Overview

Tilenga is the project name for the devt of petroleum resources of contract area1&the Northern part of the license area2 located in Buliisa and Nwoya district in Uganda. Total Ug is leading the devt activities in the Tilenga project area

The name Tilenga is derived from the 2local names for the Uganda KOB(Antelope), called Til in Acholi and Engabi in Lugungu

Anticipated benefits,some of which are already visible.

. Improved infrastructure such as roads,

. Business opportunities eg supply of goods and services to the oil companies and their contractors

. Employment 4both skilled & unskilled jobs

. 6 Oil fields

. Over 30 wellpads

. About 400 wells will be drilled

. 190,000 barrels per day of oil at plateau production

. 1 Central Processing Facility(CPF)

The Central Processing Facility(CPF)

The Tilenga industrial area based in kasenyi in Buliisa district will be the base of operations for the CPF,with other permanent facilities such as operations camp,operations supply base and temporary facilities...

such as the construction camp and construction base. Within the CPF itself,there will be oil,water and gas separation facilities,water treatment facilities and the oil trains to transport the crude oil. The project will be developed using two CPFs.

The North(TILENGA) CPF consists of four crude separation trains,and will be used to process reservoir fluids from the Buliisa fields, this CPF will be developed to process 190k barrels.

The Central Processing Facility(CPF) will also comprise of;

Oil Separator

The fluid that comes from the reservoir to the CPF consists of oil,water,gas and other impurities. The primary purpose of the oil separator is to remove the oil from these other fluids. The different fluids that come to the CPF have varying

properties(density,viscosity, boiling point etc) and the separator uses two parameters of pressure and temperatures to separate these.

Water Treatment

The water treatment facility within the CPF will be used to treat water from lake Albertans produced water separated from the produced oil. The water specification required will be stringent enough to ensure that the water re-injected

into the reservoir does not block or clog the reservoir components.

POWER GENERATION

Associated gas encountered during the production of oil will be used to generate power. To comply with our strong commitment to protect the environment,since 2000,Total

has completely routine flaring in new projects. Indeed in Uganda,we will apply zero flaring policy. Therefore we are concentrating our efforts on alternatives to flaring and particularly on using associated gas to produce electricity as well as processing

it into liquefied gas. All the associated gas produced has to be used to generate power so that oil production is not constrained.

WELL PADS

A total of about 400 wells will be drilled from 34 well pads in order to minimise the project's footprint.

Well pads will be constructed on land of 8-12Ha. The wells will consist of both production and injection wells. A network of interfield pipelines will collect the oil production from each wellpad and transport it to the CPF located within the industrial

area outside Murchison Falls National Park. Additionally,there will be an earthbound around each wellpad on which vegetation will be grown to enhance blending with the green environment. This aims at minimising any of visiual impact

WELLS

Over 400 wells are going to be drilled, using simultaneously 3drilling units over a period of 4.5 years. Between 12 and 20 wells will be drilled in 1 well pad. In addition,the horizontal well technology is going be used

These two methods methods will reduce the environmental footprints of the project.

INTERFIELD LINES

Pipelines will be laid for the transportation of fluids as follows;

FLOW LINES

These will carry well pads production(crude oil and natural gas) to a CPF and feed injection water fro the water abstraction station to the CPF & the well pads

FEEDER LINES

These will transport crude oil from the CPF to the delivery point near the refinery in Kabaale village. The length of the pipeline from Buliisa to the delivery point is estimated to be approximately 100km. All pipelines will be buried with

registered conditional surface right of ways restricting land use to carrying degrees

LAKE WATER ABSTRACTION STATION.

The CPF will also be connected to a water abstraction plant on the shores of lake Albert to provide make-up water. In order to maintain

reservoir pressure during production of oil,water will be injected back into the reservoirs through the injector wells. Initially, water will be extracted from lake Albert and transported vie pipeline to the CPF for treatment before its pumped to the well

injectors. While the amount of water abstracted reduces over time(for instance by using the water separated at the CPF), the infrastructure will still be useful for supplying water to the CPF for the other uses.

CAMPS AND YARDS

Permament Camps

Activities undertaken in the production phase will require staff to remain on the ground for long periods. The Tilenga project will require the construction of: (1)a base camp and (2) an operational support camp 2accomodate

field staff and contractors respectively. The camp will be located within the industrial area which encompasses the CPF. An additional yard facility will be located ,North of the Murchison Falls National Park,Nwoya District during the operational phase.

TEMPORARY CAMPS

Construction and drilling activities will require staff,contractors and equipment to remain on the ground temporarily for the duration of construction phase. Camps,yards and lay-out areas for CPF and pipeline construction are required for

about four years while temporary camps for drilling activities maybe required for up to six years

ROAD NETWORK

The project will construct and maintain access roads that connect the main roads to Buliisa and Nwoya district. Additional access roads to well pads and other infrastructure will be added

Road transport is expected to carry the highest percentage of the freight. The South and Northern logistic bases will be supplied with equipment and material independently hence minimal need for barging across the the Victoria Nile.

In order to manage traffic we will adopt the looping concept for one way traffic. Traffic will enter though Masindiriad and exit through Buliisa/Hoima road

BUGUNGU AIRSTRIP UPGRADE

he upgrade and or extension of the existing Bugungu airstrip is anticipated in the development phase. The works on the airstrip will involve upgrade of the runway, construction of a hanger and apron,traffic control function

jet A1 storage facility and lighting. These upgrades enable the airstrip manage higher traffic using bigger aircrafts.

NILE BARGE CROSSING

During the operation phase of the project,there will be need for teams to monitor and supervise the unmanned well pads north of the Nile, no camp is envisaged in the North so the operators will have to routinely cross the Nile

for regular maintenance and inspection on the well pads and flowilnes North of the Nile. The planned oil and gas dedicated barging and jetties on the Nile,125m away from the Paraa area will serve the above purpose with minimal interference of the tourism

traffic.

CARING FOR THE ENVIRONMENT.

. Enabling the harmonious co-existance of oil development activities with the environment.

Govt Of Uganda and the Joint Venture(JV) Partners, CNOOC,Total E&P Uganda and Tullow Uganda Operations PTY ltd are committed

to protecting the environment for current and future generations in the areas where we operate.

The projects are being developed in line with the International Finance Corporation (IFC) performance standards as well as Uganda's

environmental laws to ensure that the development of Uganda's oil resource is done with minimal environmental footprints.

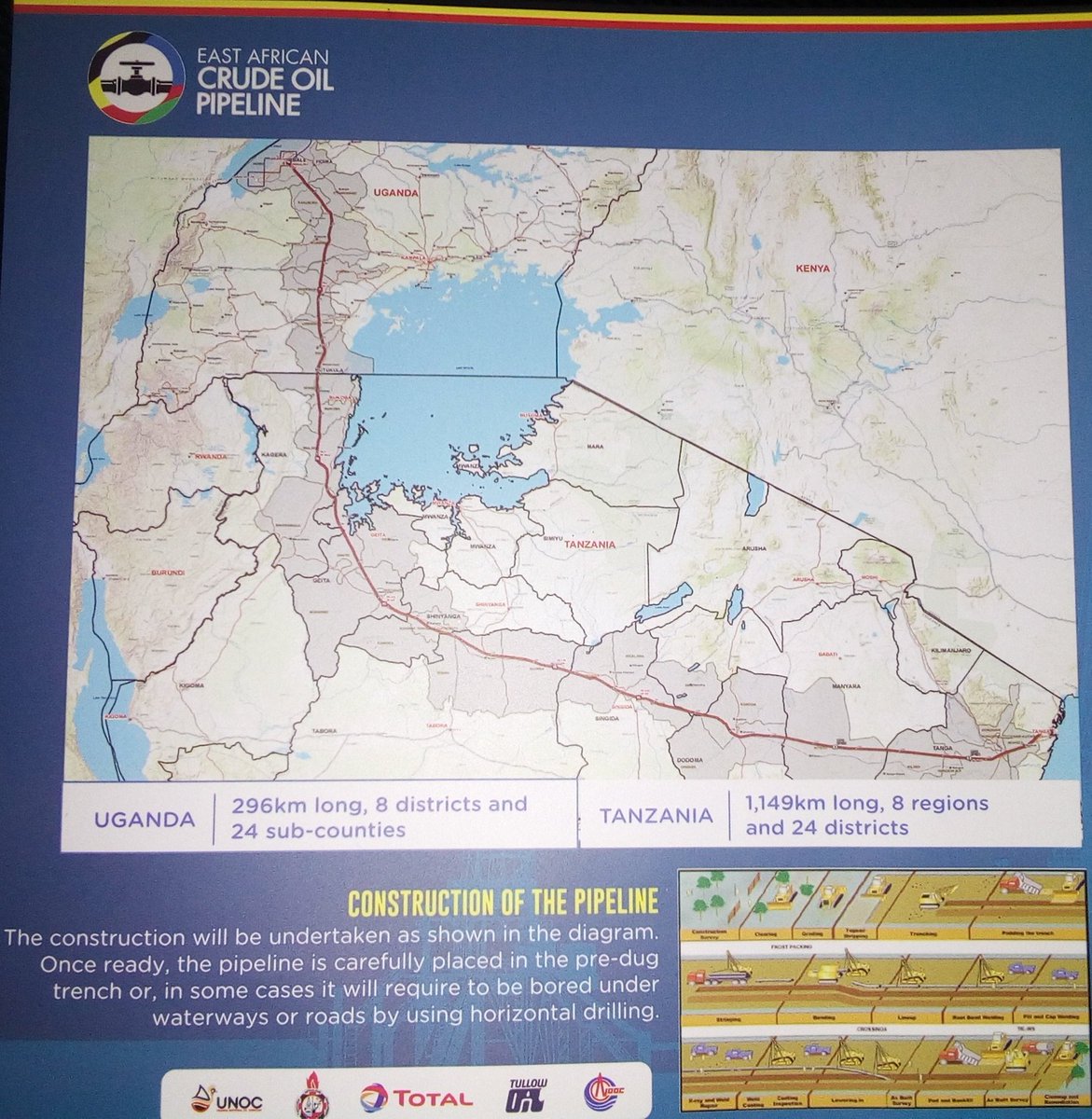

The above information is contained in a small piece titled; UGANDA: Insight into the Tilenga and EACOP Projects.

Thanks to @PAU_Uganda and the entire team.

Lastly, I hope to create time and tweet about the Environment & Social Impact Assessment.