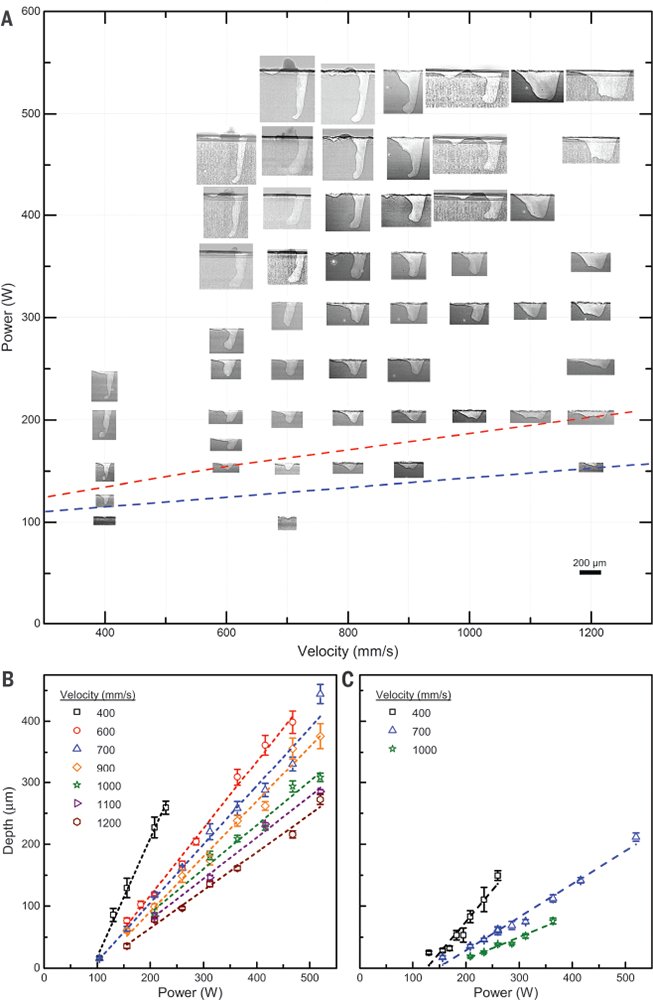

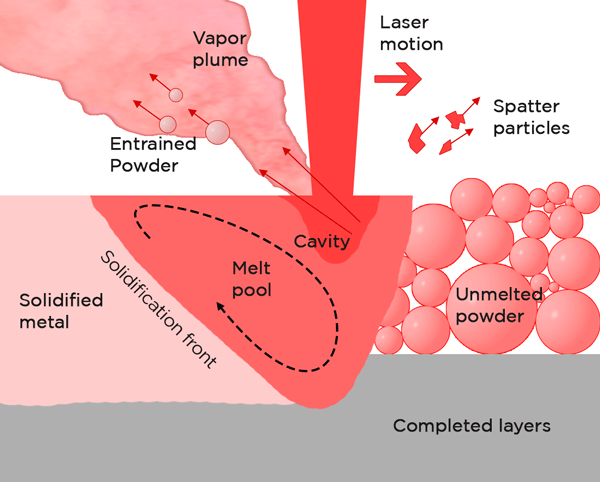

Dynamics of the process in one image (which I re-drew due to legal issues for the presentation😂). Key takeaway: this process has A TON of parameters/levers to pull on an already highly stochastic process.

#AdditiveManufacturing

(Img researchgate.net/publication/33…)

- Powder size distribution

- Particle morphology

- Chemistry

- Re-use of the powder

To ensure high quality metallurgy of outgoing parts.

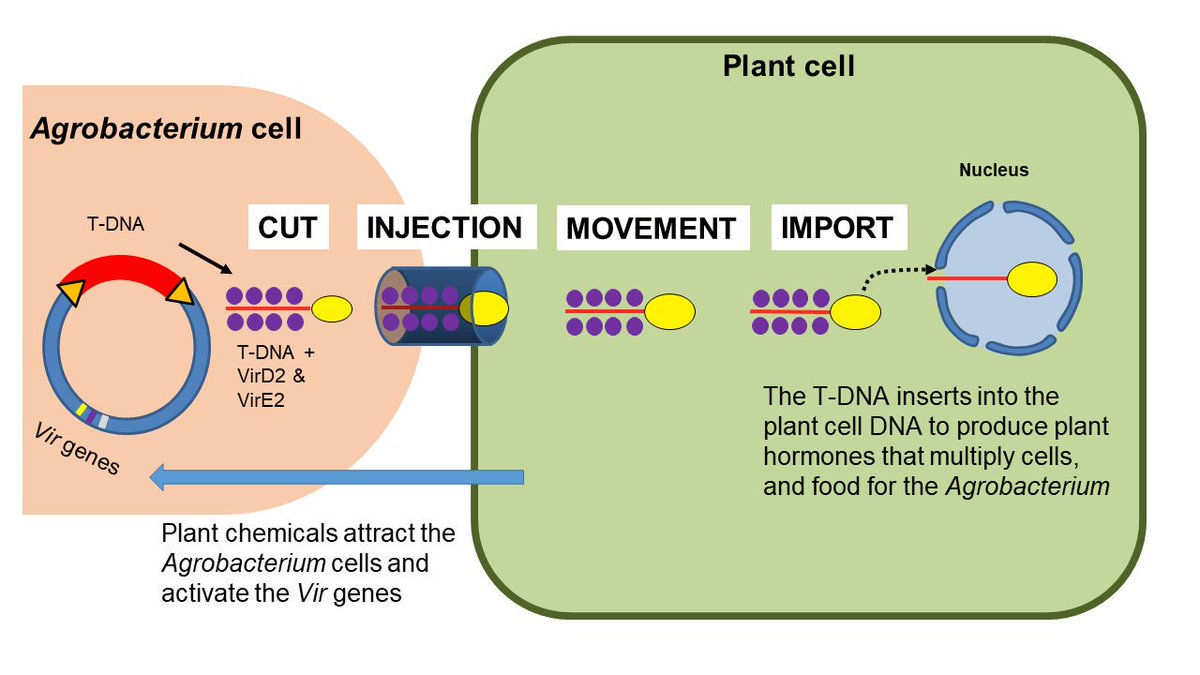

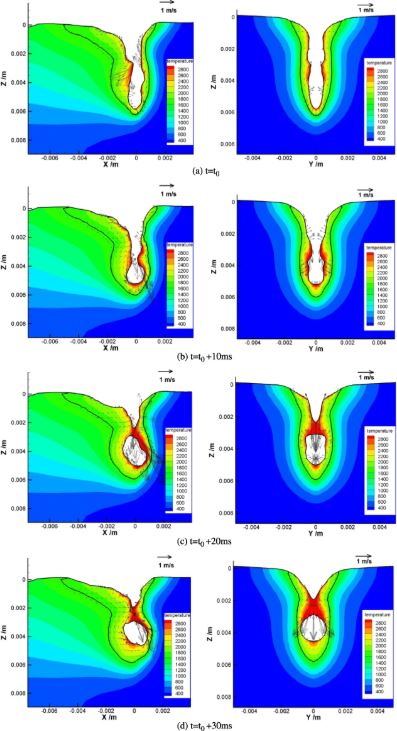

In the meltpool itself, a vapor depression is formed in the top of the pool, and the fluid is recirculating through Marangoni flow. Particles are pulled into the meltpool due to surface tension.

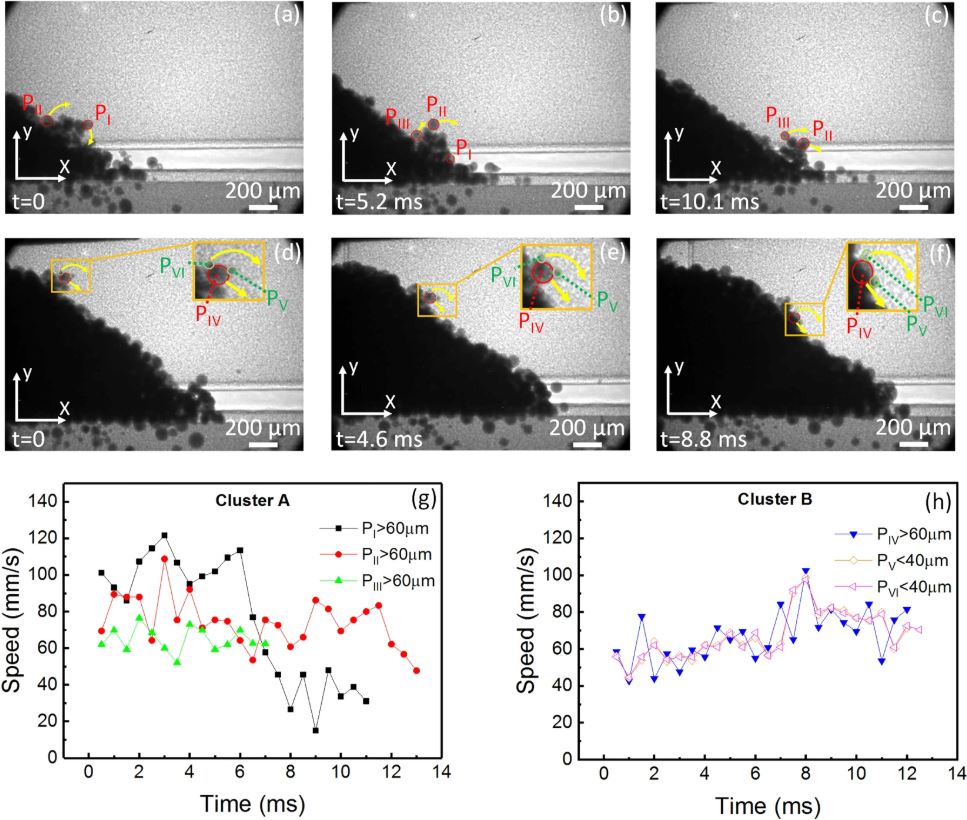

Spatter particles are ejected out of the other side of the meltpool.

(img nature.com/articles/s4159…)

(Also at @Livermore_Lab and @OfficialUoM)

nature.com/articles/s4159…

nature.com/articles/s4146…

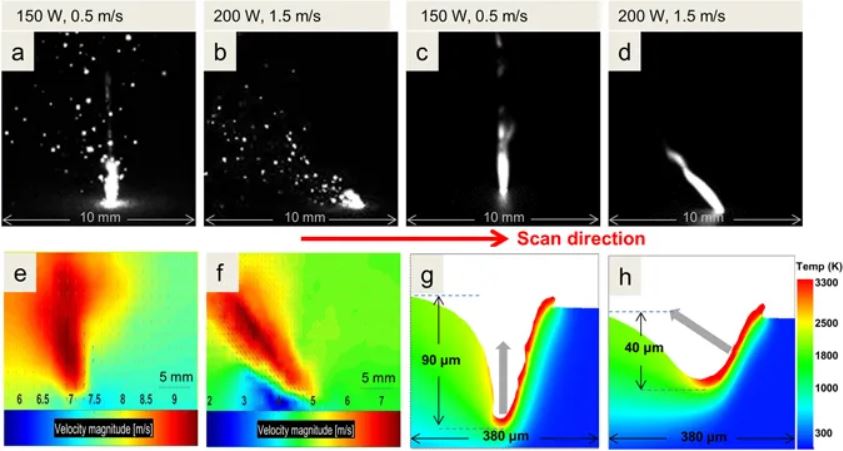

What is keyhole porosity and how does it happen? Read on ⬇️.

(img iopscience.iop.org/article/10.108…)

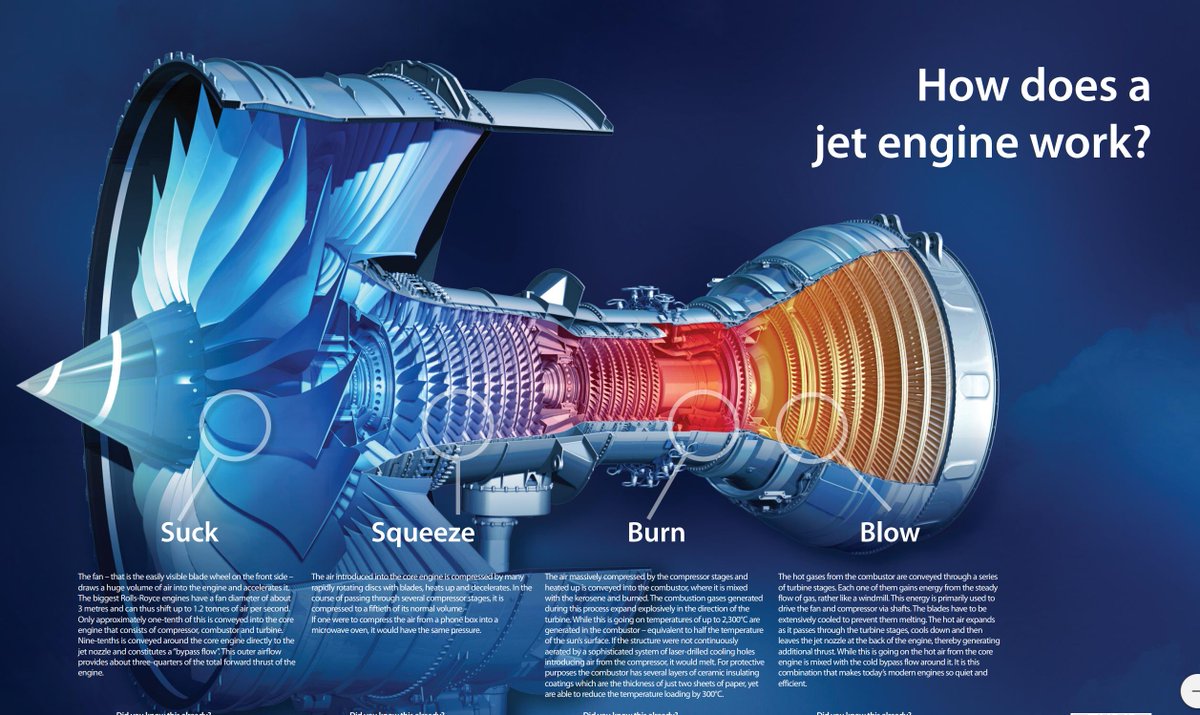

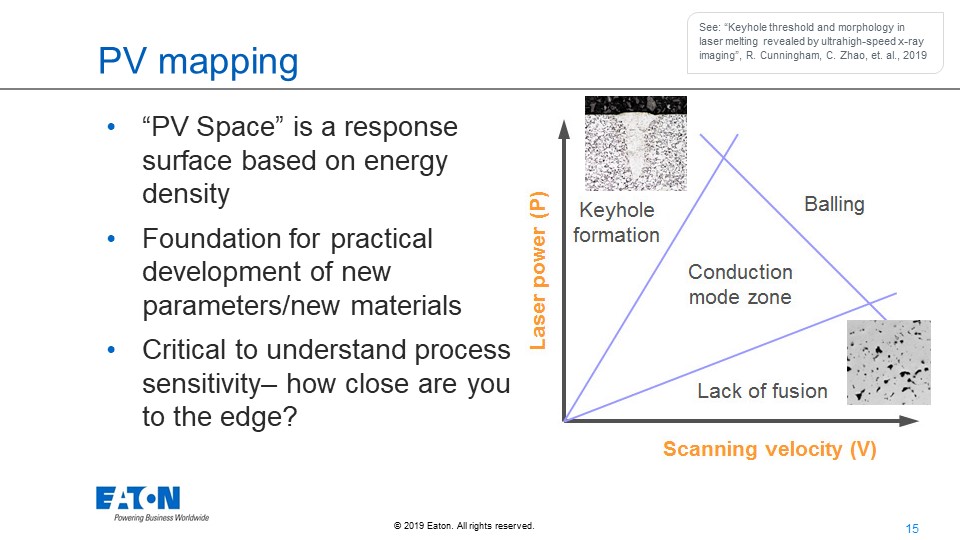

~ Too hot + too slow = keyhole formation

~ Too cold + too fast = lack of fusion

~ Too hot + too fast = balling (laser track balls up vs. straight line)

~ Too cold + too slow = turn the machine on 😛

(img @jul_coh)

So, how sensitive is your process? You'd better know if your laser power fluctuates by ±3%, speed by ±5%, that you're still inside the triangle.

(img science.sciencemag.org/content/363/64…)