Hello everyone, I'm your host @MySci_PK and today's science story is going to be about "Gecko inspired hybrid adhesive system" 🦎

Here we go! 😁

Correction: everything COOL we see.

The geckos' superpower, if I may say so, definitely falls in the COOOOL category!

I mean, at this point the focus must have been on NOT capturing geckos, giving them pedicures and then borrow their feet.

1. has to be flexible

2. easy to handle

3. easy to clean (cause you know, no one wants to spend hours cleaning in the lab 🤪)

Metals - Difficult to clean

Most materials - Difficult to handle

The only category left is - POLYMERS! 😁

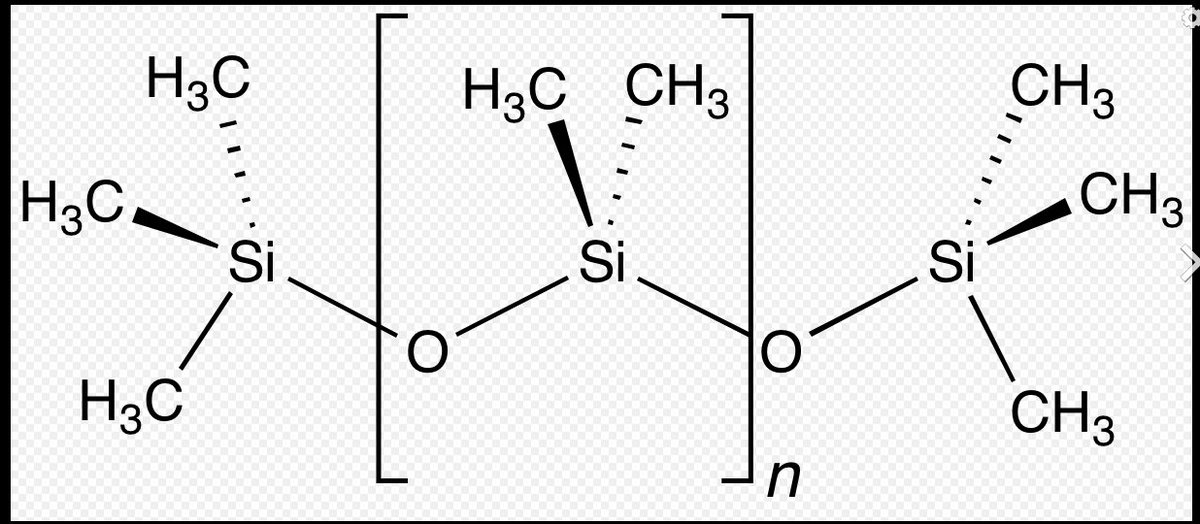

They narrowed down to this one special polymer called Polydimethylsiloxane (PDMS).

The name sounds scary, I know. 😊

Does this help? 😊

Please come back, I have got a pretty picture of PDMS for ya! 😉

pic is a screenshot from Elveflow website.

Also resembles the gecko foot hair.

We got a match! 😁

Now let us proceed with making the hairy foot in the lab! 😉

Next challenege : to make TINY structures out of PDMS. 🧐

1. make a mold

2. pour semi-ready PDMS in the mold

3. let the PDMS become ready

4. remove from the mold

and TADDAAAA, PDMS hair are ready!

We decided to make microstructures instead of nanostructures. And now I will tell you why.

PS: don't take this 👇gif personally. 🤣

We didn't just make a gecko-foot, we went a step ahead and made it better! 🤠🤓

The thermal expansion coefficients of PDMS is 20 times larger than gold.

This means that the gold-coated side will be stiffer compared to the bare-PDMS side.

At room temp, the pillars stand straight.

During this time the gold coated side of the pillar is stiff in which case the expanding PDMS tried to overpower (read: bend) the pillar.

BUT as soon as the temp rises, the pillar bends and the contact is lost - > adhesion lost. 🤓

The idea came from my supervisor's brain with me doing the groundwork! 🤠😉

If you have any questions, please, feel free to ask me here (until tomorrow) or on my private account (@MySci_PK). 😊

Thank you for sticking till the end! 😁

*The End*