It was fascinating. 👍

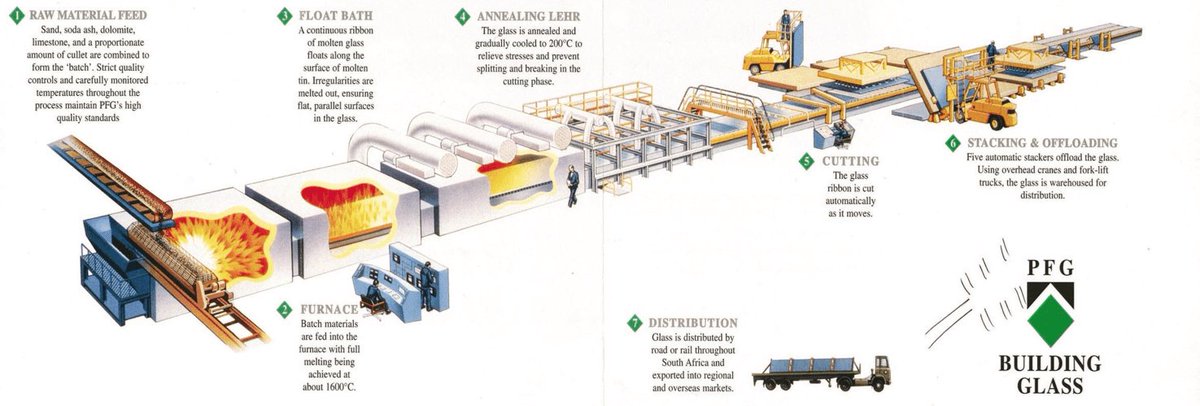

So here's a small thread about how theses big wide glass sheets are made.

Different types arrives by train🚂 and are unloaded on a conveyor belt below the track🛤

The different ingredients are precisely mixed ( silica, sodium oxide, lime, probably others) with a small part of recycling glass🍾

It takes 2/3 days⏳ for the batch to go from one end to the other.

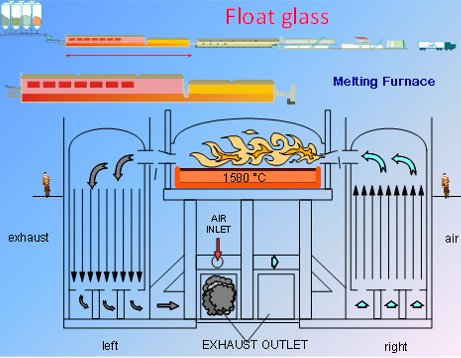

The furnace is approx. at 1500 °C and the glass come out near 1100°C.

The furnace is heated by huge heater/flamethrower💨🔥 and change side every 20min.

Also, the furnace runs for 15 year without interruption 👀

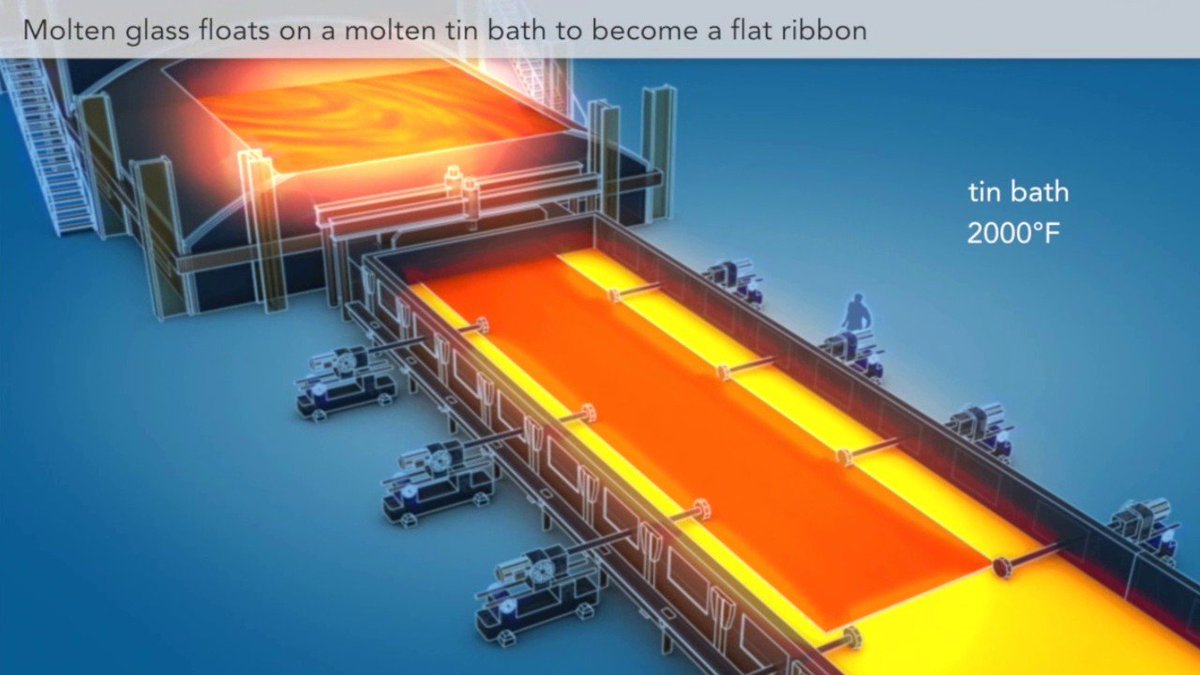

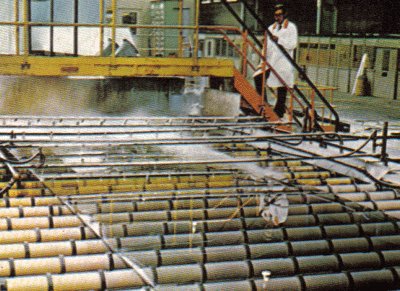

Like tons of tin! and the glass float on top in one big sheets. really.

That way, the glass go out the furnace and cool slowly on a perfectly plane surface.👌

It is pulled by gear⚙️ wheel, which control the width of the glass sheets by changing its rotating speed

The faster the wheel⚙️, the thiner the glass in the end💯

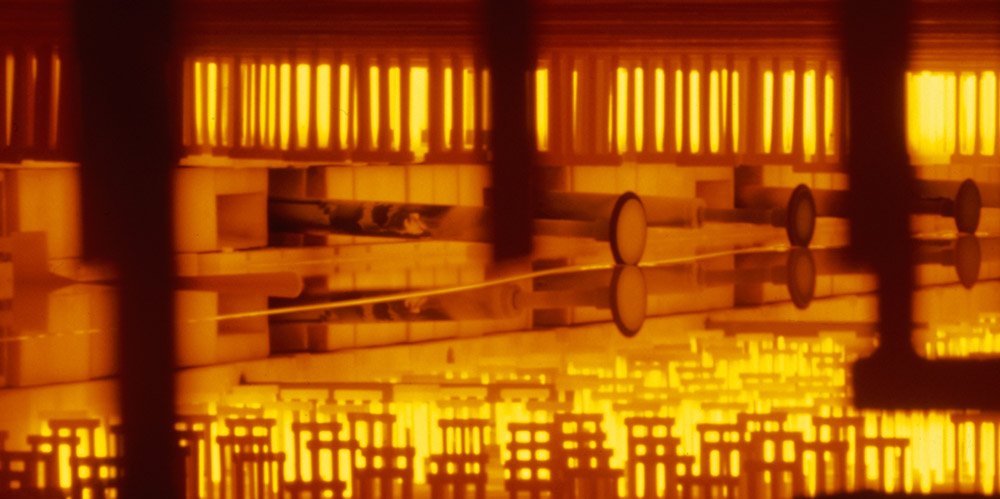

The glass is still under a lot of stress😰 and need to be gradually cooled down to 200°C🤒

If the cooling process is not perfect, the ribbon could break😵

Bubbles, sand grain, ripples can be found. It uses for :

- Understanding and refining the process 🧠

- Defining the quality of the output, and the cutting🔪 process.

Medium and good quality is finally cut from the ribbon🎬, according to the order book📕

The glass ribbon is at least 100 meters long 😨 (or maybe more i never measured)

And it runs for 15 years non-stop 🤯

Also, while frustrating, seeing the ribbon break can be oddly satisfying 🙃

Here's a sum-up of the process