⚡️twitter.com/i/moments/9266… #fuelcyclefriday

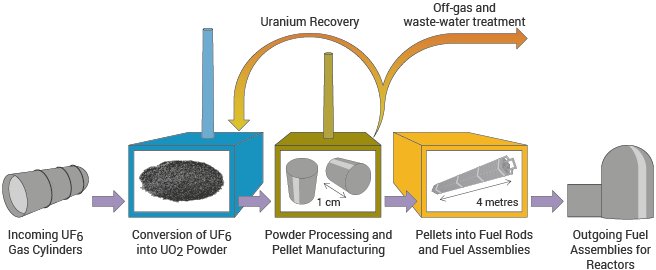

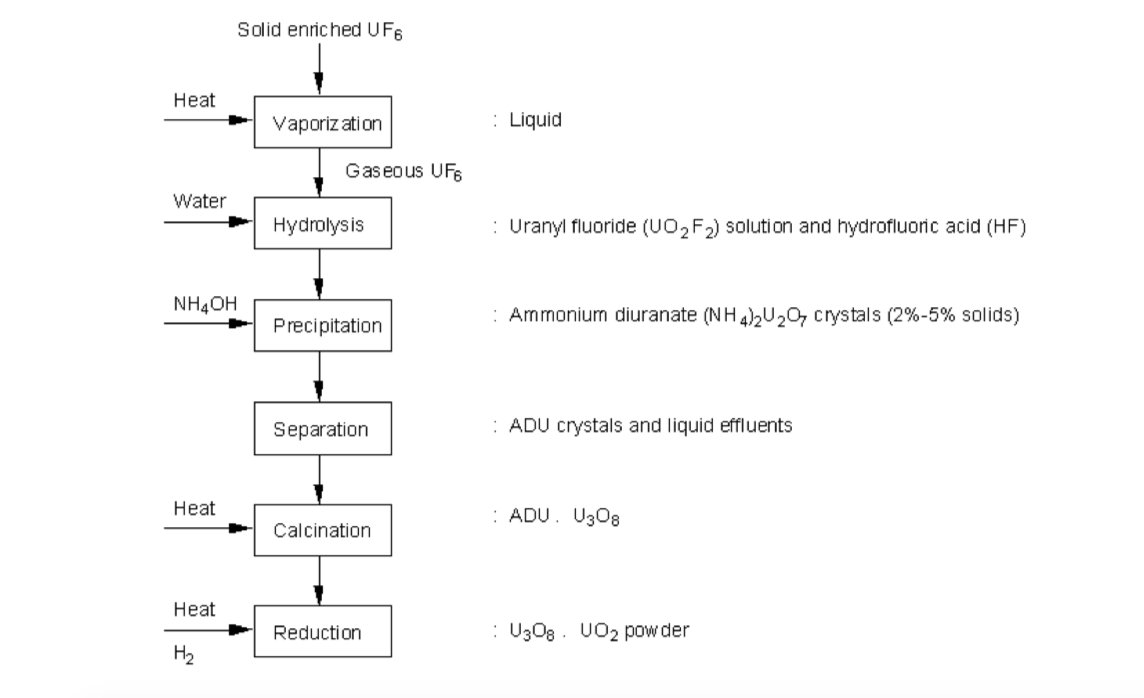

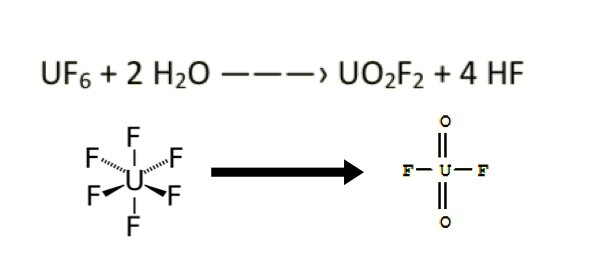

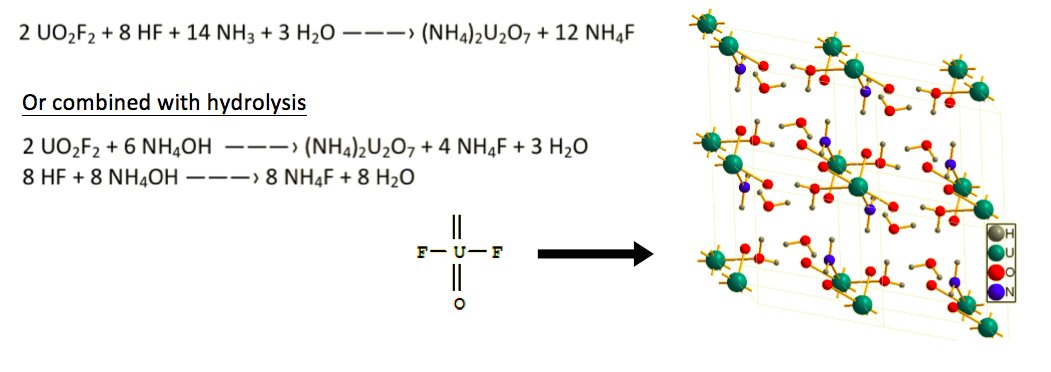

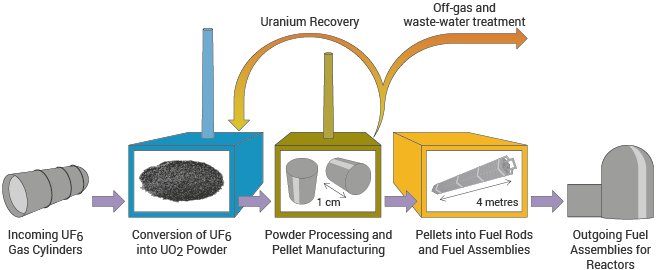

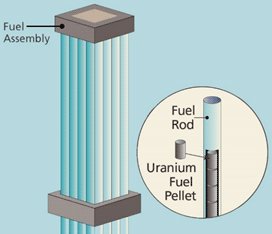

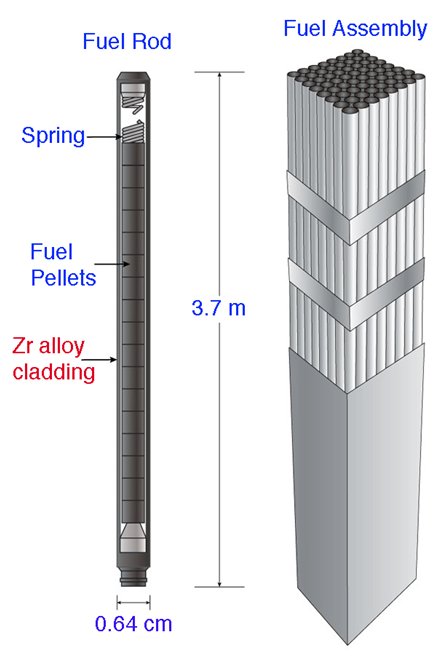

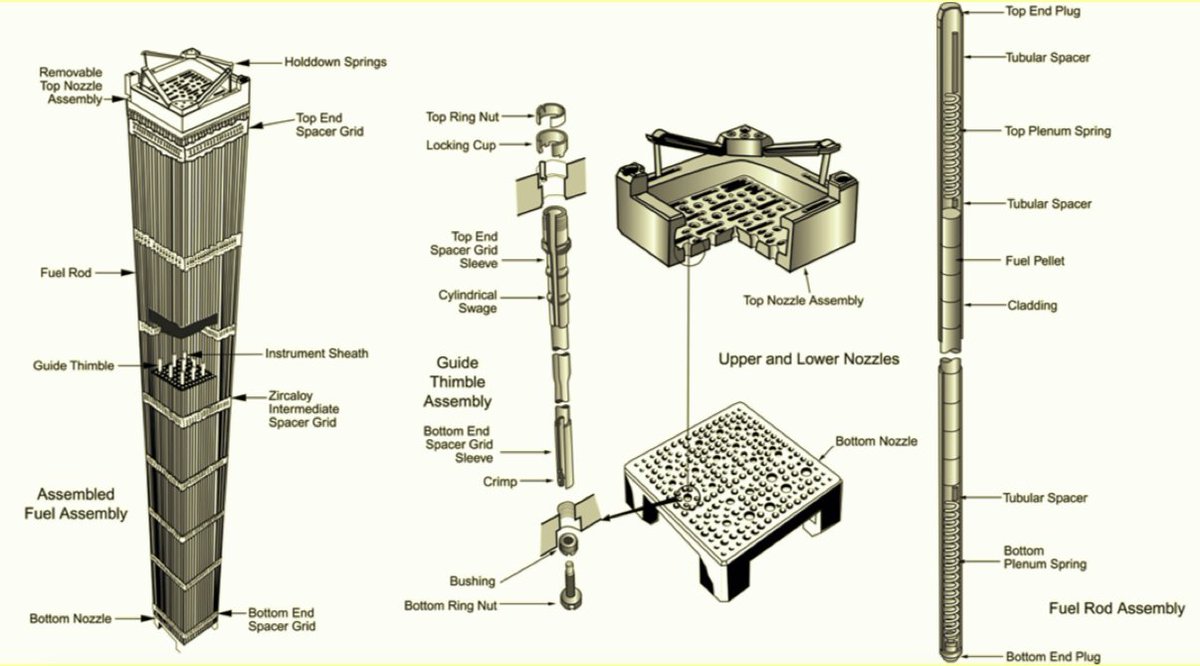

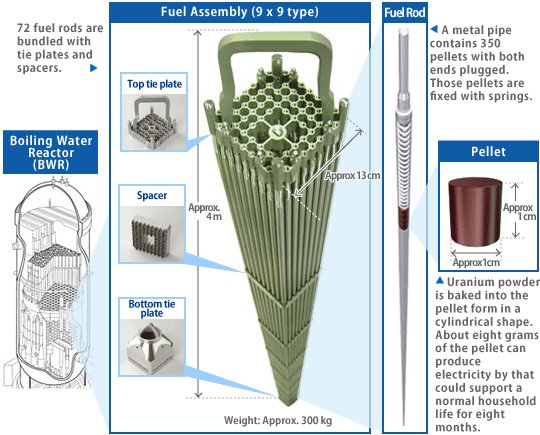

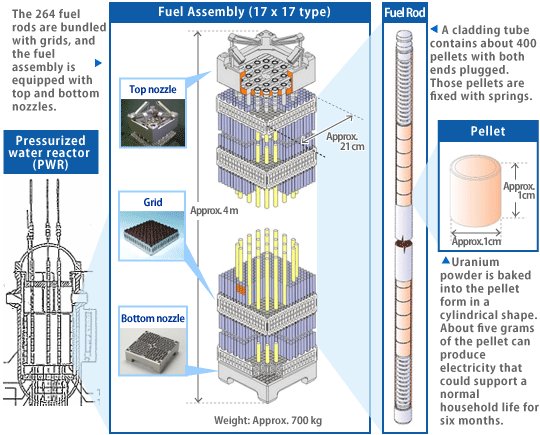

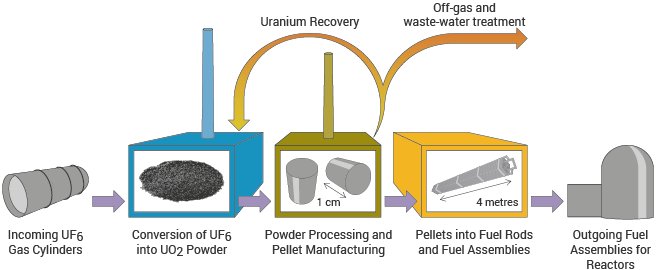

- producing UO2 powder,

- forming and sintering the UO2 into pellets,

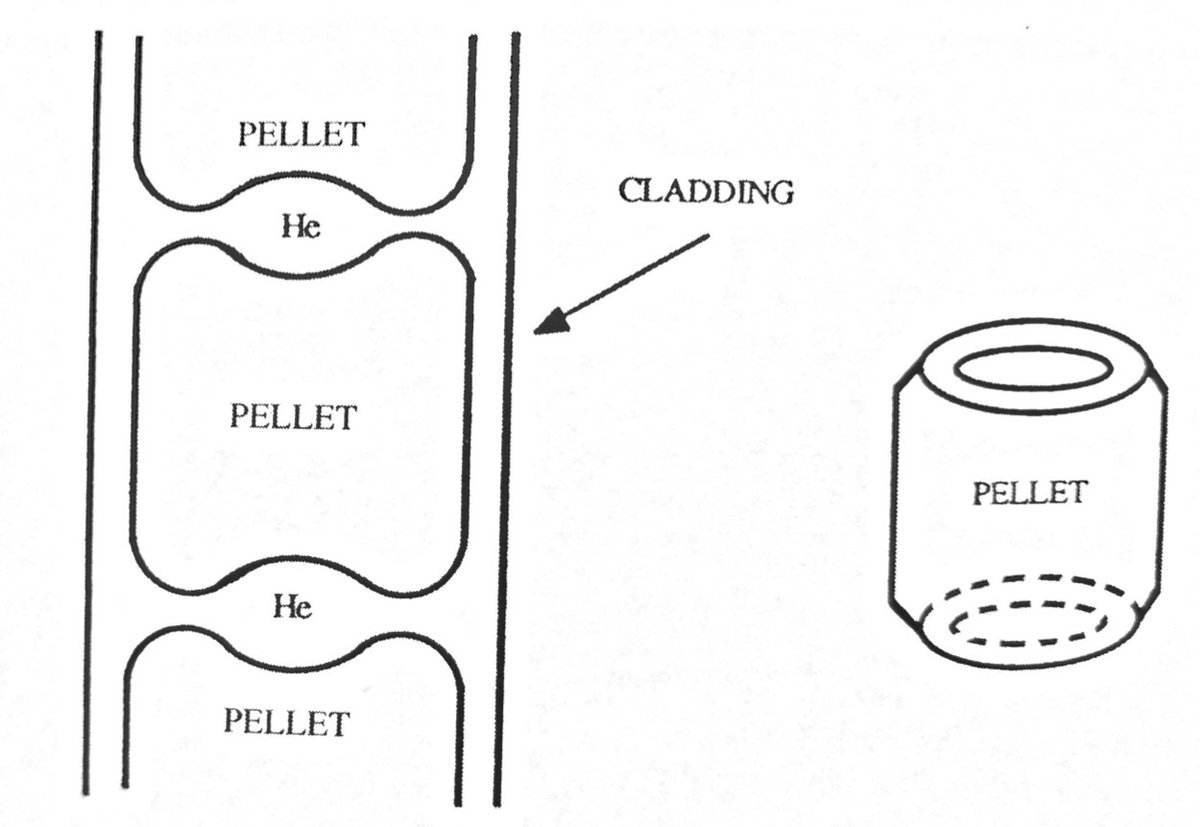

- loading and placing the pellets into rods and assemblies,

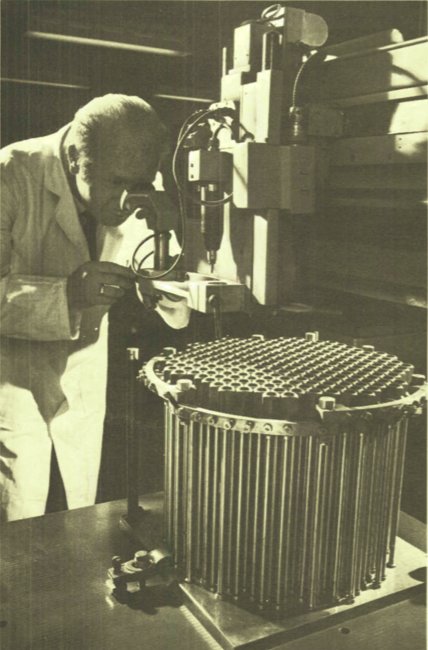

- quality assurance #fuelcyclefriday

📸: @WorldNuclear

#fuelcyclefriday 📸: @NRCgov

#fuelcyclefriday 📸: Getty

#fuelcyclefriday 📸: @FAScientists

#fuelcyclefriday

#fuelcyclefriday 📸: @Alchetron

#fuelcyclefriday 📸: @Alchetron

#fuelcyclefriday

#fuelcyclefriday 📸: ScienceSourceimages

#fuelcyclefriday

📸: @WorldNuclear

#fuelcyclefriday 📸: @NRCgov

- Corrosion resistant

- Able to withstand high pressure, heat, and radiation environments

- Low cross section i.e. doesn't readily absorb neutrons

#fuelcyclefriday

#fuelcyclefriday 📸: @cameconews

#fuelcyclefriday

#fuelcyclefriday

#fuelcyclefriday 📸: NFI

📸: @WorldNuclear

#fuelcyclefriday 📸: @iaeaorg

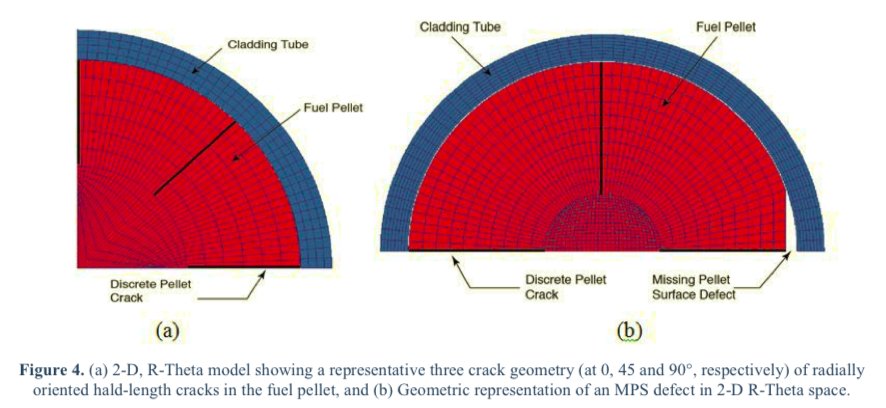

#fuelcyclefriday 📸: CASL

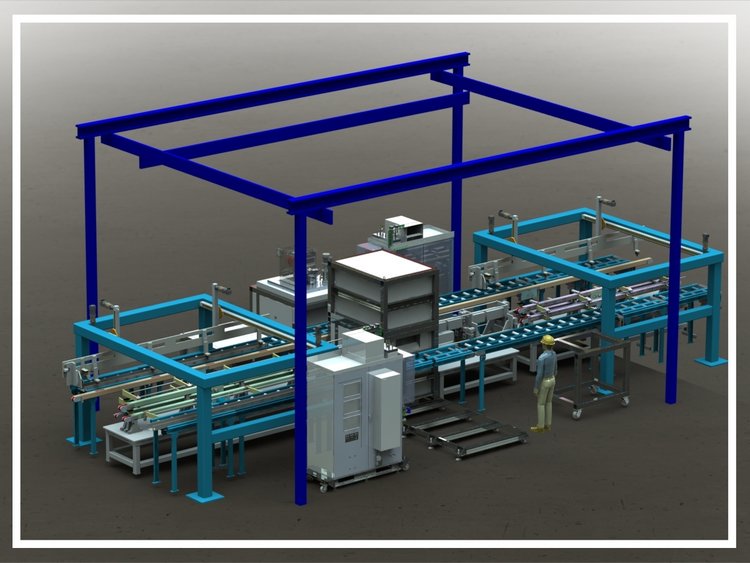

#fuelcyclefriday 📸: SABIA

#fuelcyclefriday 📸: Phoenix

#fuelcyclefriday

- Nuclear Fuel and its Fabrication by @WorldNuclear

world-nuclear.org/information-li…

#fuelcyclefriday

- Evaluation of UF6-to-UO2 Conversion Capability at Commercial Nuclear Fuel Fabrication Facilities by @ANL

web.ead.anl.gov/uranium/pdf/AN…

#fuelcyclefriday

and finally

- NUCLEAR FUEL FABRICATION & REFABRICATION COST ESTIMATION METHODOLOGY by @ORNL (old but still interesting)

osti.gov/servlets/purl/… #fuelcyclefriday

or check out the cool uranium glass I sell on Etsy etsy.com/shop/NuclearKa… (10% off with code HAPPYHOLIDAYS)