Here is the sing-along version of "grading and abetting - does timber strength grading help or hinder the circular economy" at the #TIMBER2019 conference of @wood_technology of @iom3 [1]

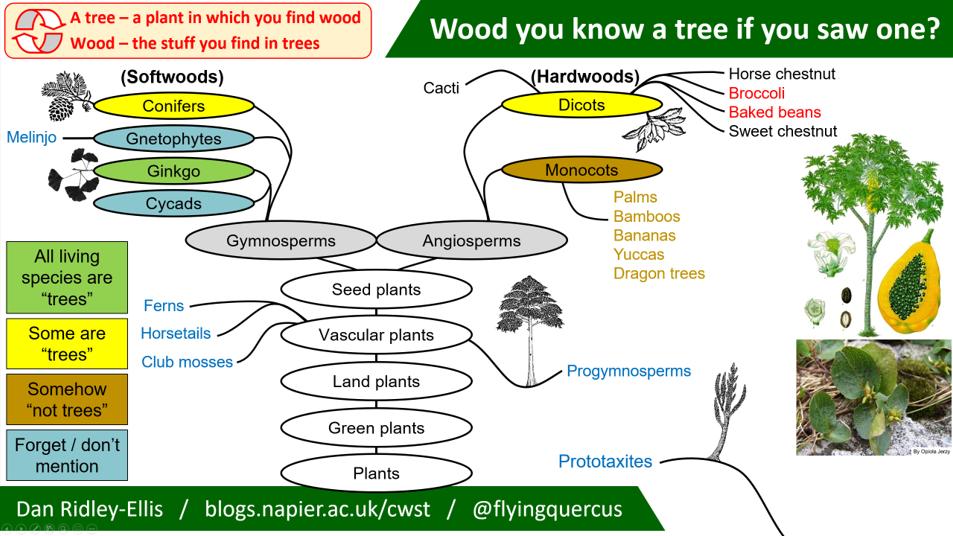

Let's return to this topic of how words shape our thinking, not always for good [3]

For more see blogs.napier.ac.uk/cwst/beyond-gr…

(for more blogs.napier.ac.uk/cwst/why-gradi…)

[23] blogs.napier.ac.uk/cwst/what-is-t…

blogs.napier.ac.uk/cwst/introduci…

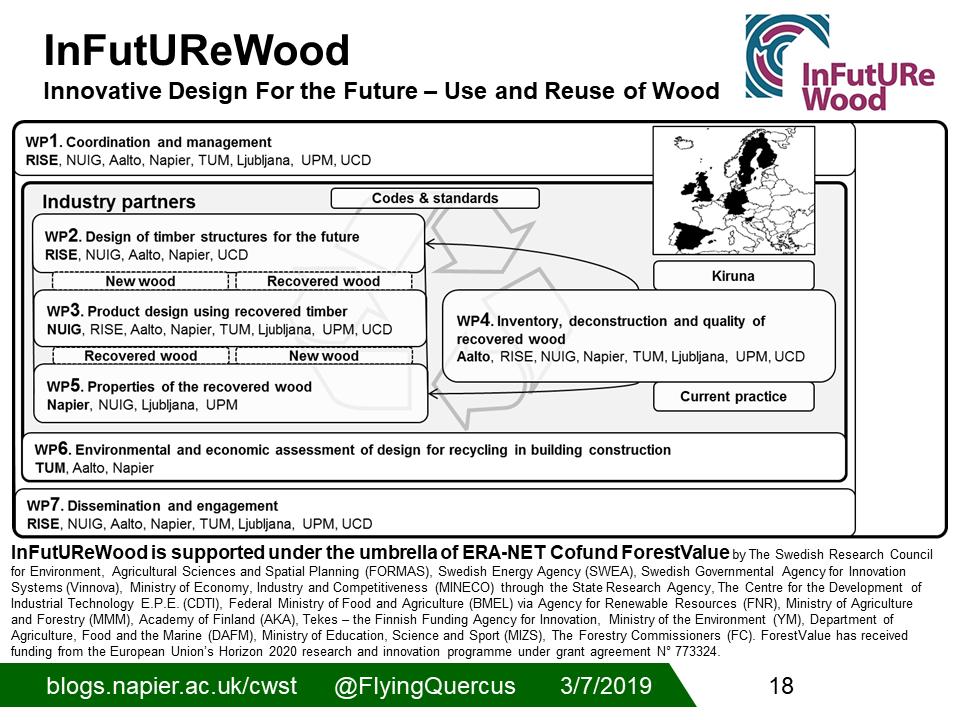

For more info on our work, see blogs.napier.ac.uk/cwst/