seda.uk.net/events/green-d…

No spoilers

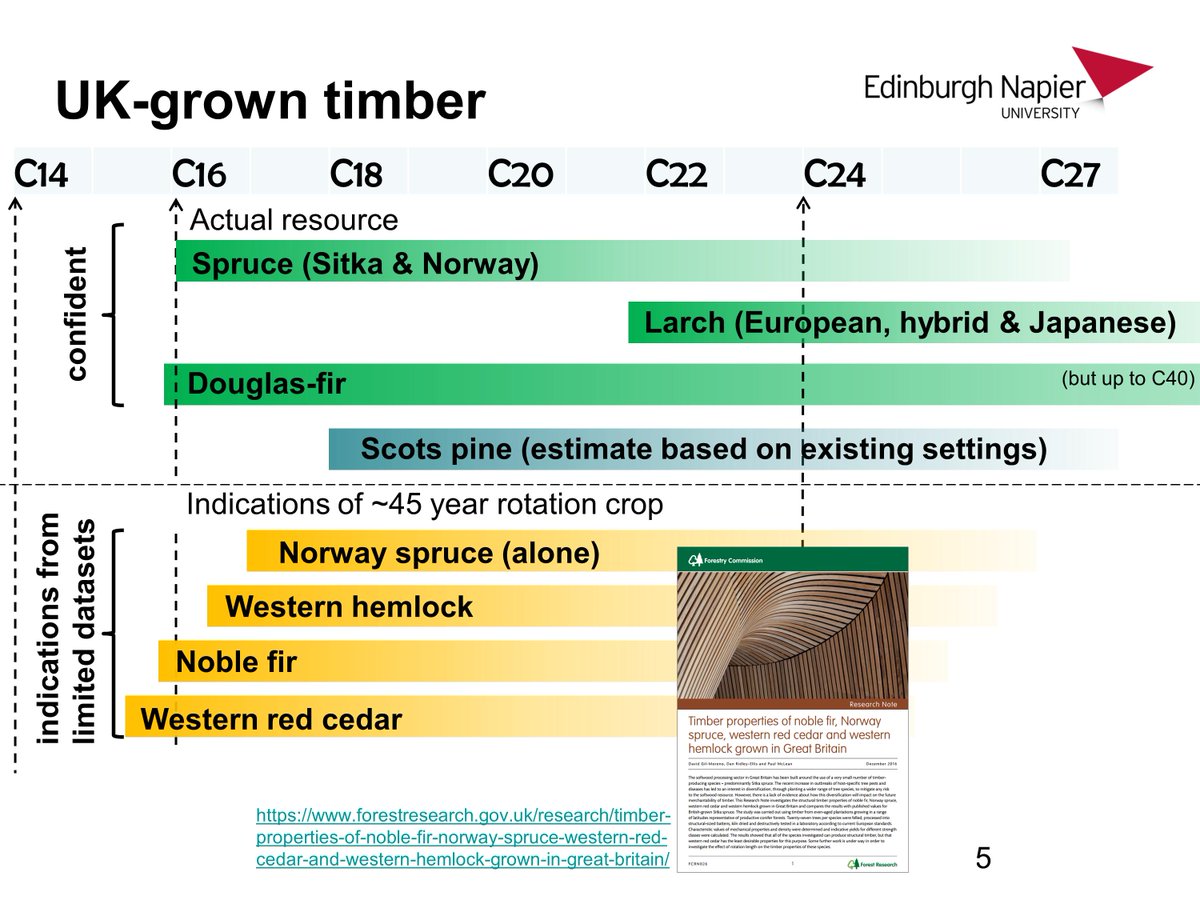

We are still working on "minor" species, started with these forestresearch.gov.uk/research/timbe…

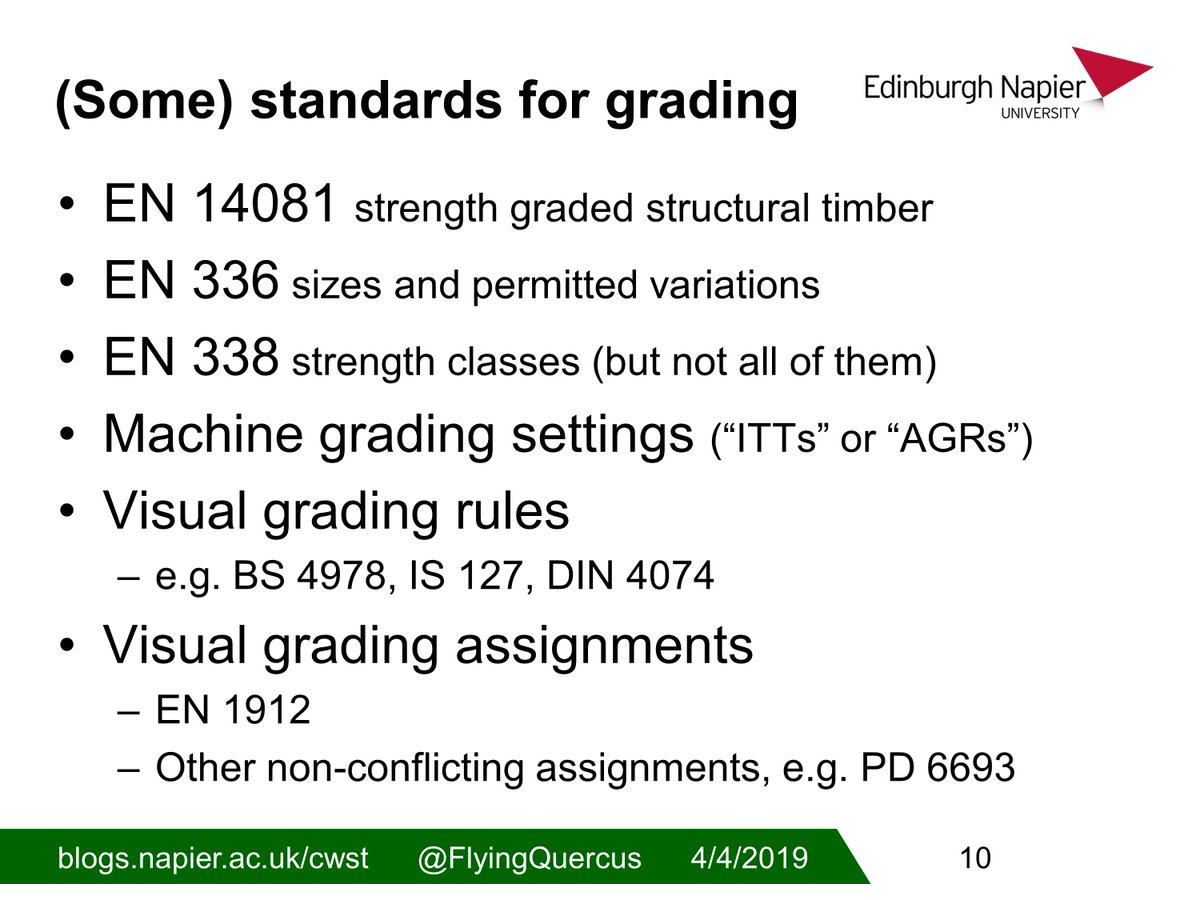

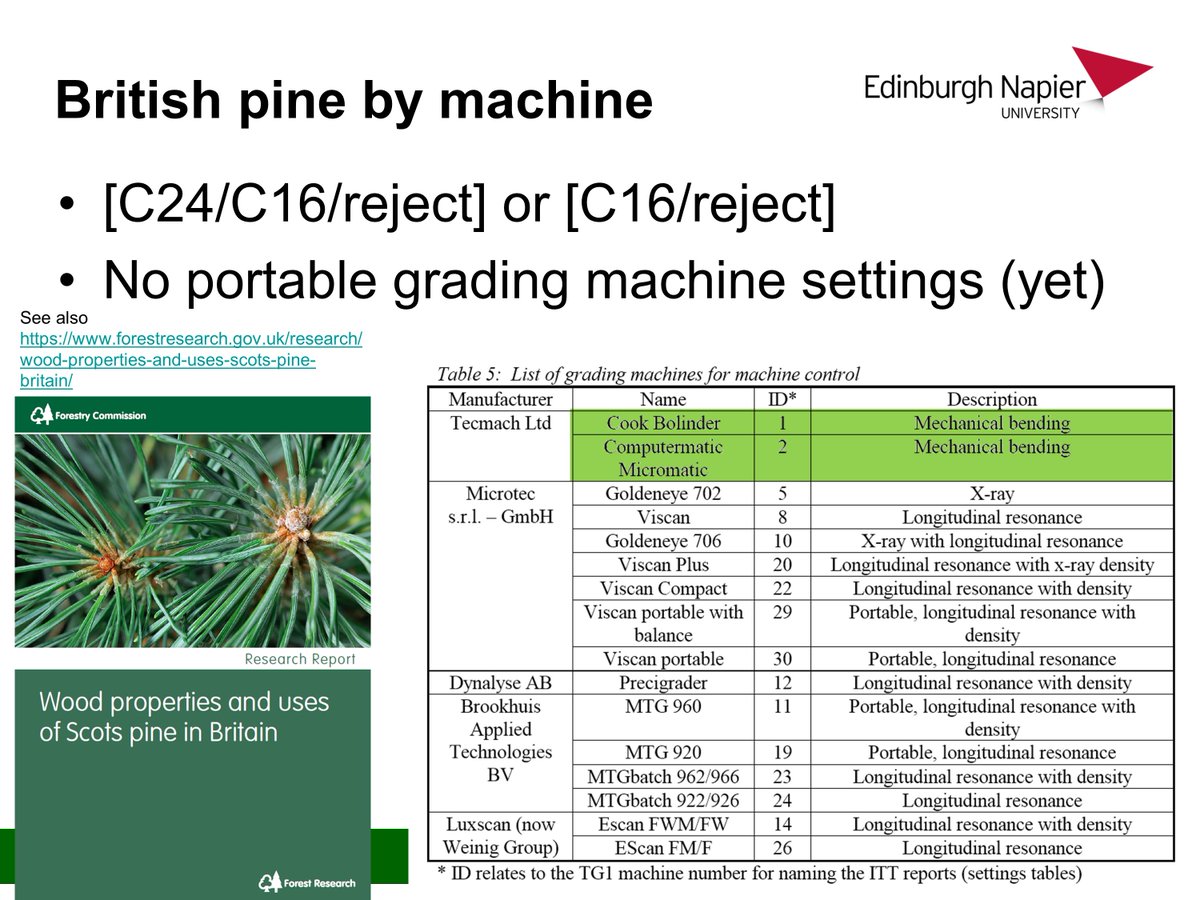

Another portable grading machine is also made by Microtec - the Viscan portable microtec.eu

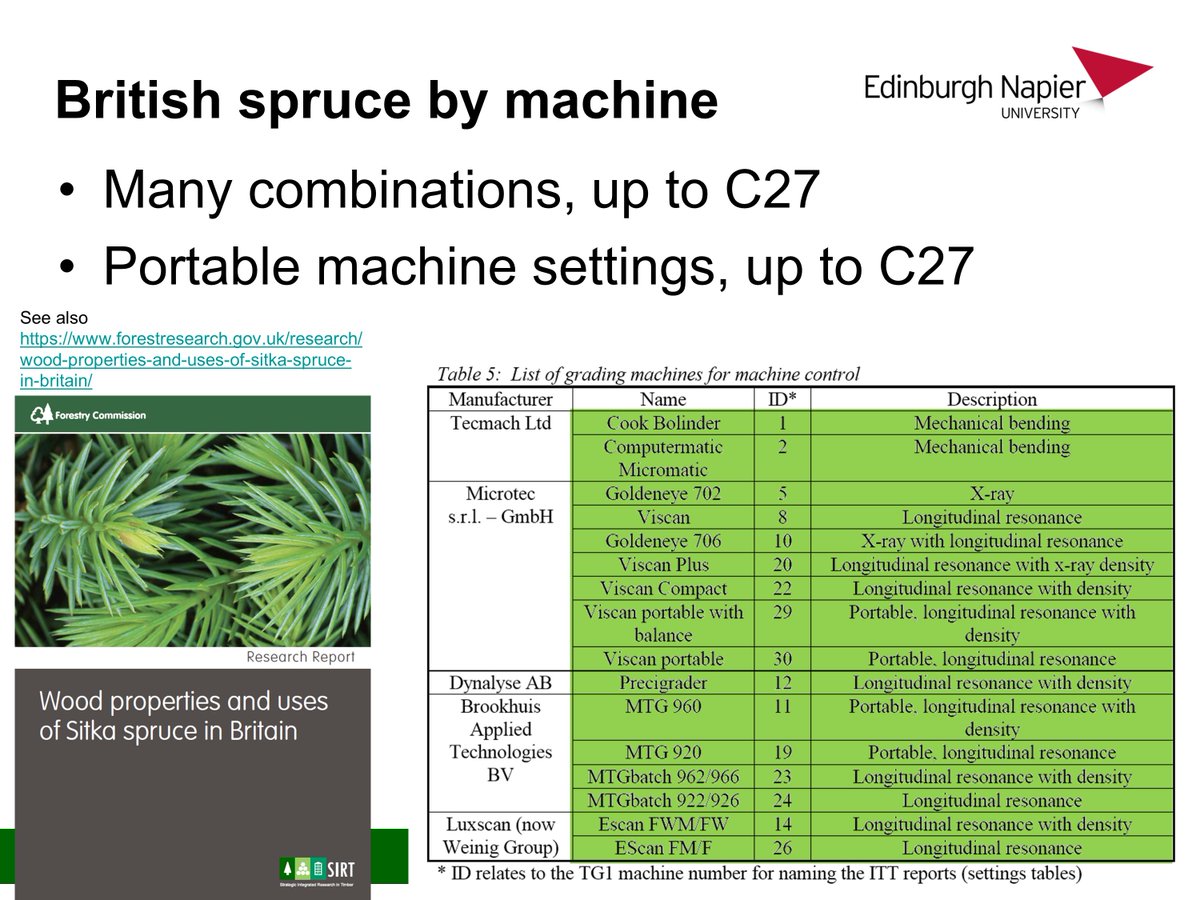

See also forestresearch.gov.uk/research/wood-…

See also forestresearch.gov.uk/research/wood-…

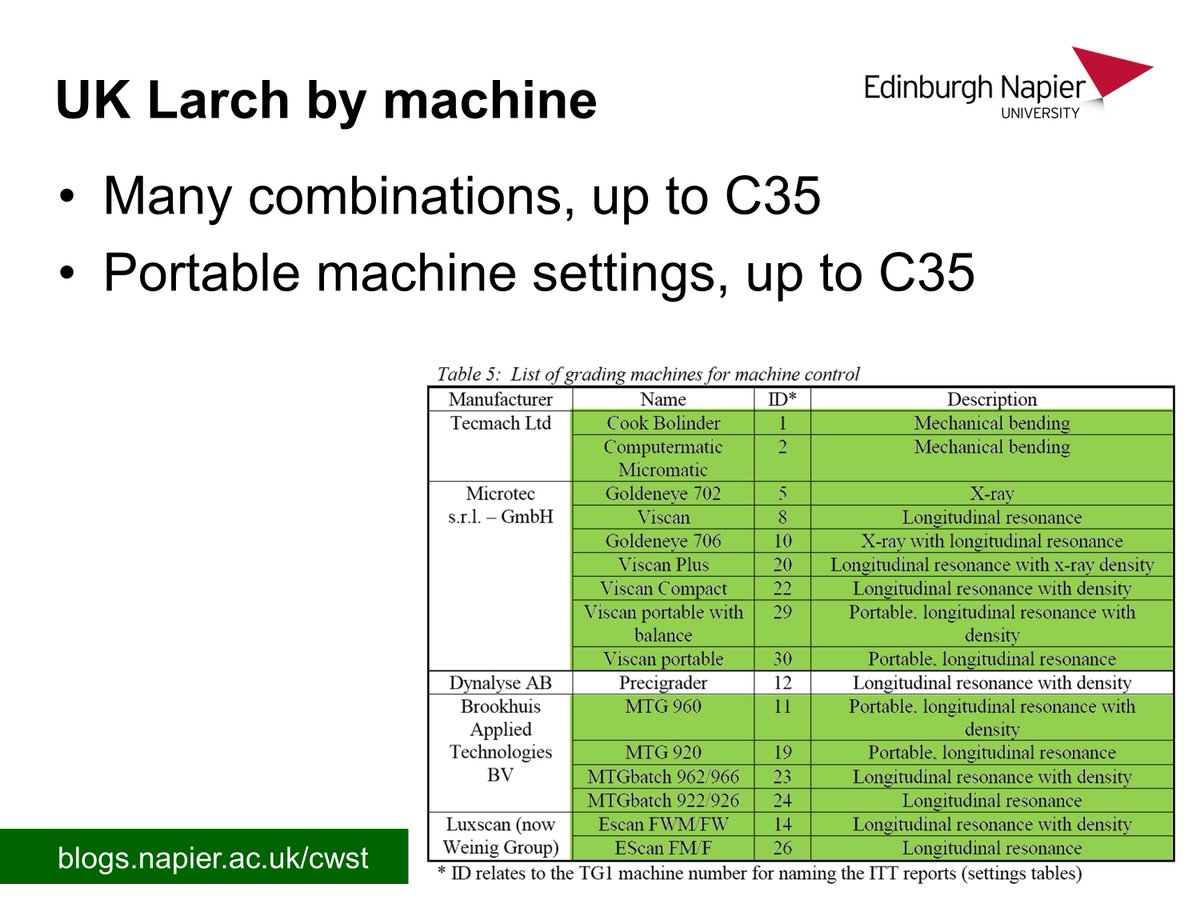

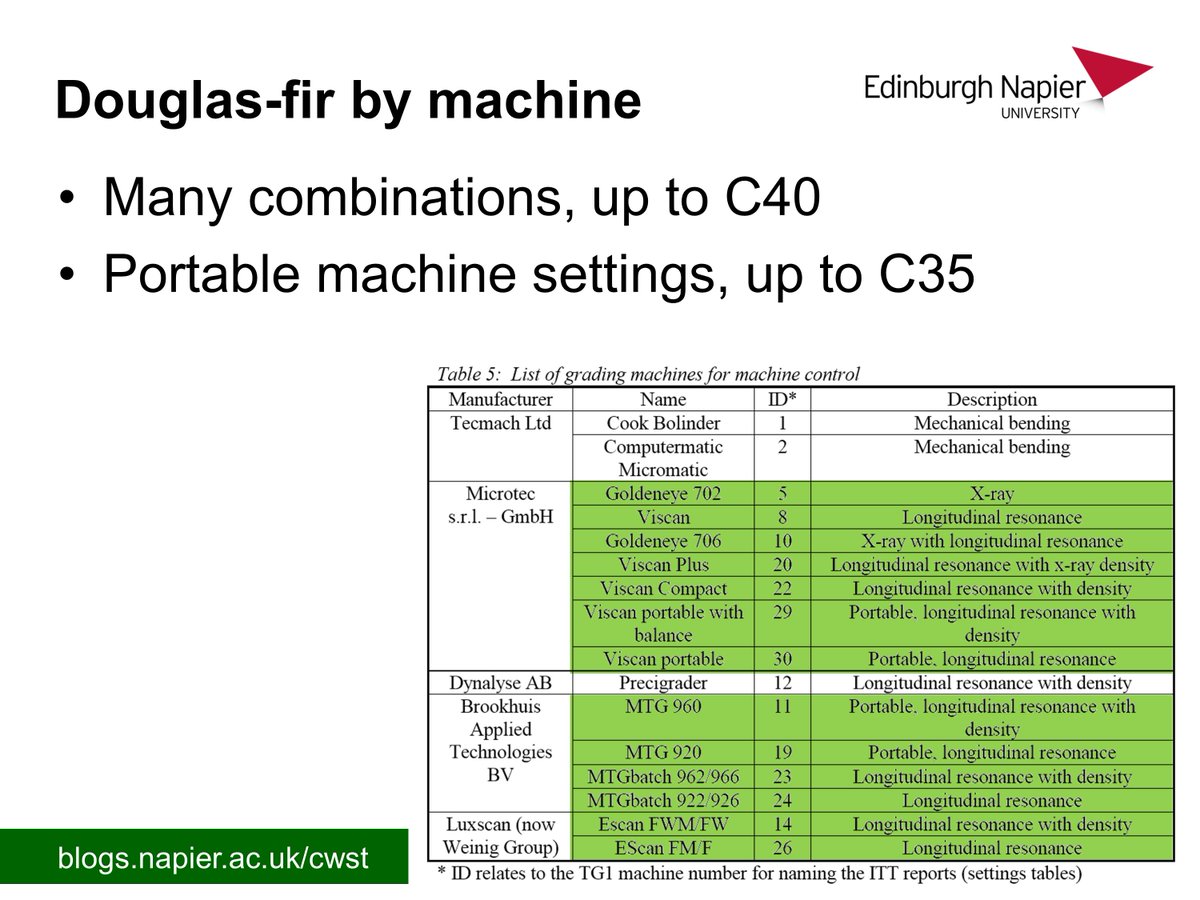

(for a full list of all grading machines for machine control in Europe see blogs.napier.ac.uk/cwst/grading-m… )

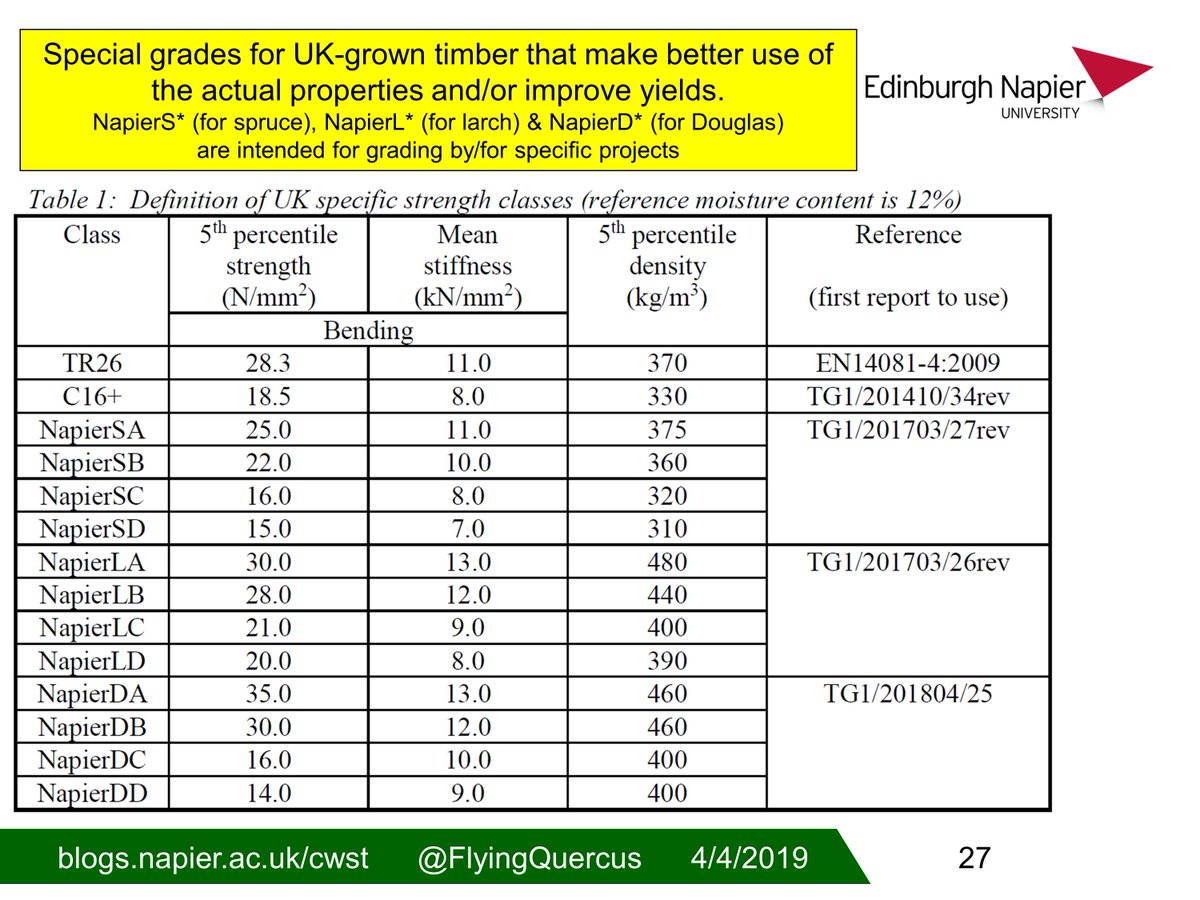

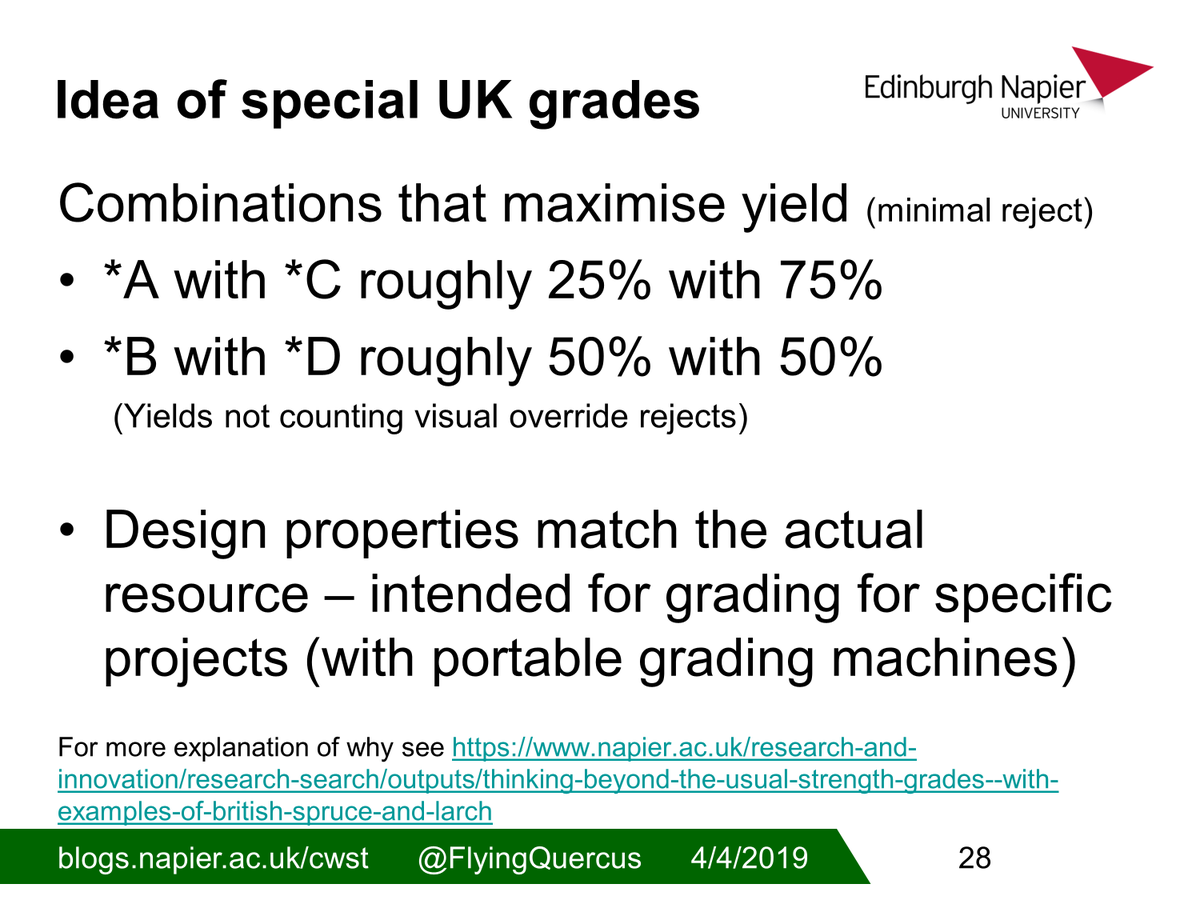

For more explanation of why see napier.ac.uk/research-and-i…

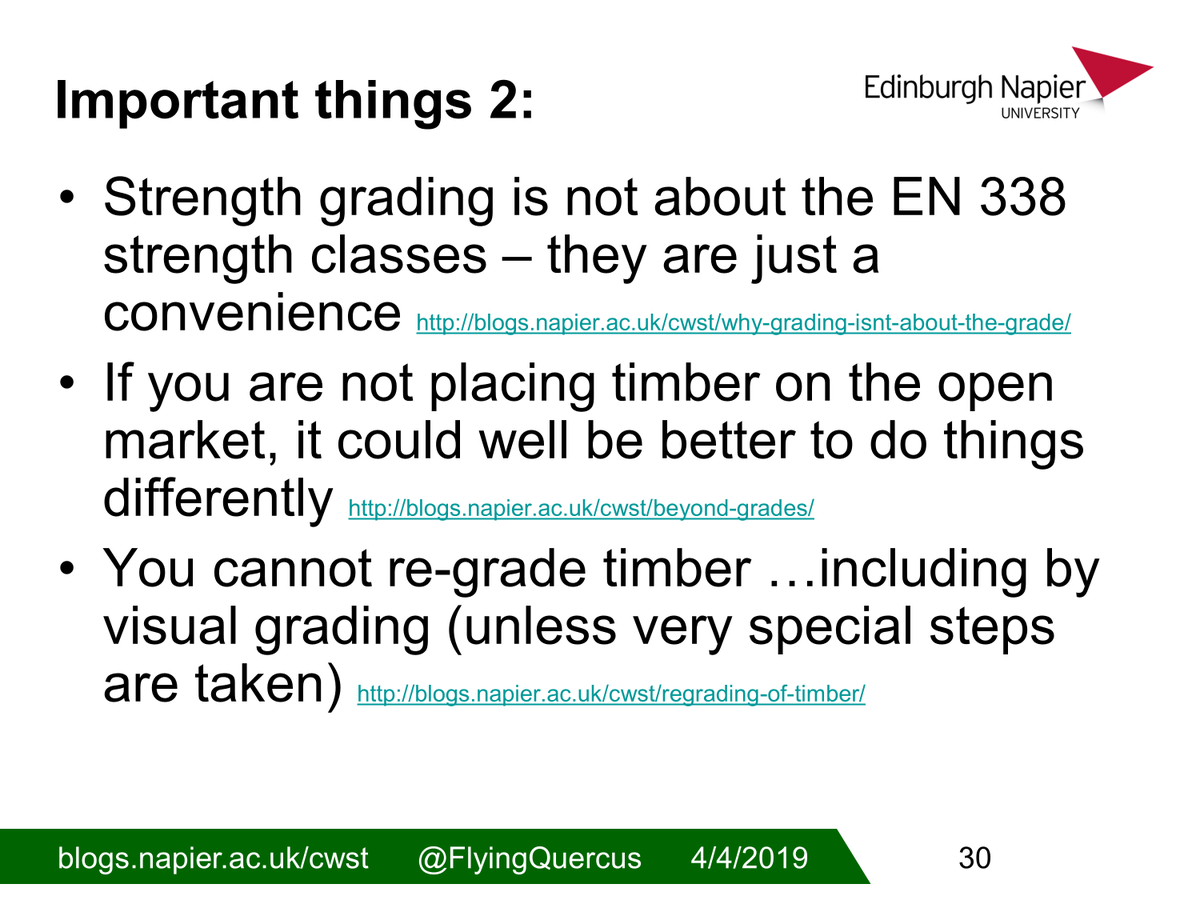

Thinking differently: blogs.napier.ac.uk/cwst/beyond-gr…

Regrading: blogs.napier.ac.uk/cwst/regrading…

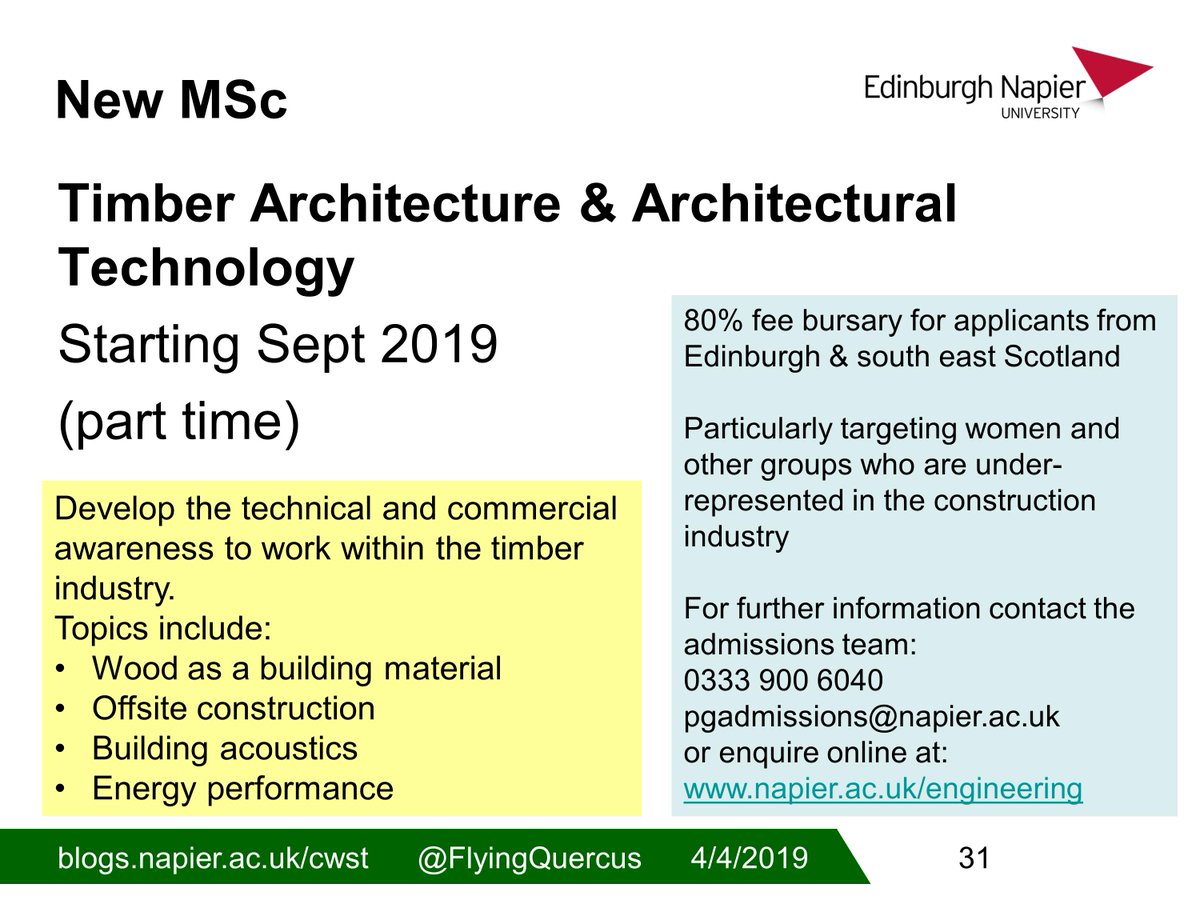

napier.ac.uk/engineering