Larger businesses are taking up new technology faster than small

NBN complaints have fallen as rollout has accelerated, belying media narrative

Cyber security: 30%+ of surveyed biz had a major cyber incident in past year. 80% of biz were investing in cyber security, up from 20%+ in our 2017 report

Enabling investments in infrastructure;

Improved collaboration between business, research, government

Managing successful economic transitions around climate and circular economy

Help SMEs take up new opportunities in global economy

Flexible IR

Trish White, Nat President of @EngAustralia: progress so far - 2 years ago hardly anyone knew what 4.0 was, today hard to find an engineer who is unaware or unexcited.

Notes many SMEs are doing 4.0 things without labeling it as such.

Worked with a concrete pourer who used to guess when concrete ready for next pour, now use sensors to make it an exact science, improve quality and speed.

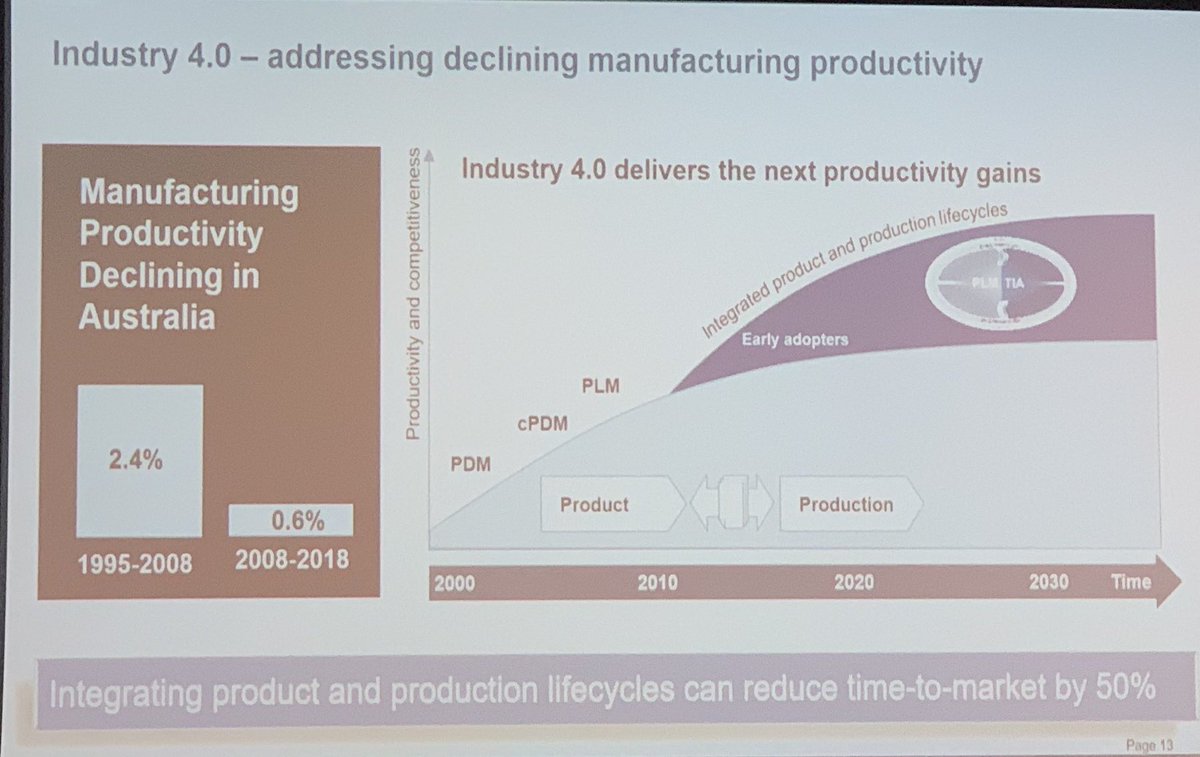

Presents a scenario where manufacturing creates more value than any other sector; and one of slow decline. We can achieve the former.

But in last 20 years the list of most innovative Aust mfg hasn’t changed

Jens Goennemann @AMGC_Ltd MD:

Digitisation and implementation are priorities in Germany because they know they don’t have a resource endowment to fall back on.

Collaboration often discussed but often a closed shop (don’t talk outside the collab) or one way street (partner gives but doesn’t get). We want to capture and share our innovation and training across industry.

Sharon: we provide information in a platform-neutral format so everyone can access.

Best process is using the most appropriate techs for context, not just the shiniest high tech, to maximize use of the available data.

What is right for very small businesses? Need lots of cloud services (light footprint) that enhance visibility of the business. Larger businesses can leverage more in-house systems.

Chris: our best collab has been with uni mechatronics students. We’re also working with the SA shipyard; it’s provided an avenue for SMEs to work with unis in a nonthreatening environment

Ian: we have projects that are utilizing AI, machine learning and blockchain. Remember past hype about algorithms however. Outputs need to be explainable. We don’t yet have needed standards for AI and ML.

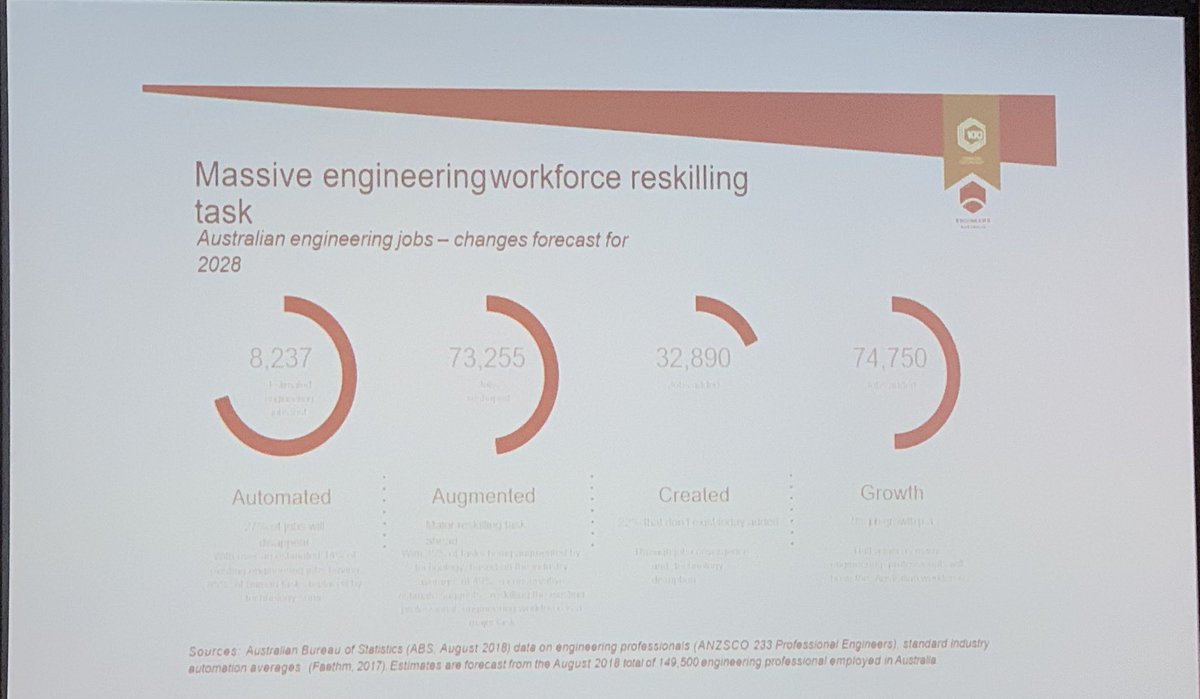

Trevor: net benefits but churn is very important. Tasks of displaced people likely to be very relevant to new labour needs, so upskilling should work. But current skills system doesn’t quite match this.

Sharon: talk to us about what you’re doing. @BAESystemsAus keen to be open with our supply chain; we have shared issues and are keen to learn as well as share.

Ian: there is a gradation of collab with big companies - sometimes purely transactional, sometimes deeper. Systems need to support the range.

Ian: varies worldwide. In Germany 4.9 is closely aligned with circular economy agenda. Open question whether this translates to Australia. Corps like @bhp see value in circular economy, will enter Aust.

Speaker 1: Australia has standards for products, processes, management systems and services. All categories drawn on for applications like smart cities.

Standards are not policy, but tech specs that support policy, market and community decisions/usage.

Product standards - Water Efficiency Labelling System (WELS) led world and is being taken global, creating markets for more efficient products and removing trade friction points.

New Australian standard for protection of privacy in orgs helps compliance with EU GDPR.

ISO9001 quality management has been adapted by medical device manufacturers to drive specific improvements

Australian industry can introduce new standards proposals here.

A: existence of standards increases business confidence to invest in 4.0 without fear of VHS/Beta incompatibilities.

There’s a critical window for standards development. If too soon or too late, will be irrelevant. Should lag market a bit. Now is right time for standardizing additive manufacturing.

If SMEs have resources to invest, they want a proven outcome.

A: there is an increasing NZ philosophy of “why reinvent global standards - unless there is something unique (earthquake readiness)”; just make sure you can participate in and influence international standards.

Moonshot program could help - eg “be most cyber-secure nation”; communication of case studies; funding for innovation and collaboration

Security of information critical, cyber standards important.

SME standard for self assessment of innovation/4.0 capability would be useful.

Early provision of information on new tech is important, prior to a standard.

Cyber is like WHS - needs repeated messaging to sustain a culture of secure practices. Cyber can be a competitive advantage. Intersection of mfg and cyber is great for learning lessons & creating competitive advantage

Explaining basic concepts remains important to building awareness.

Supplier loyalty and supply chain resilience are important.

4.0 + cyber intersection allows for new kinds of product.

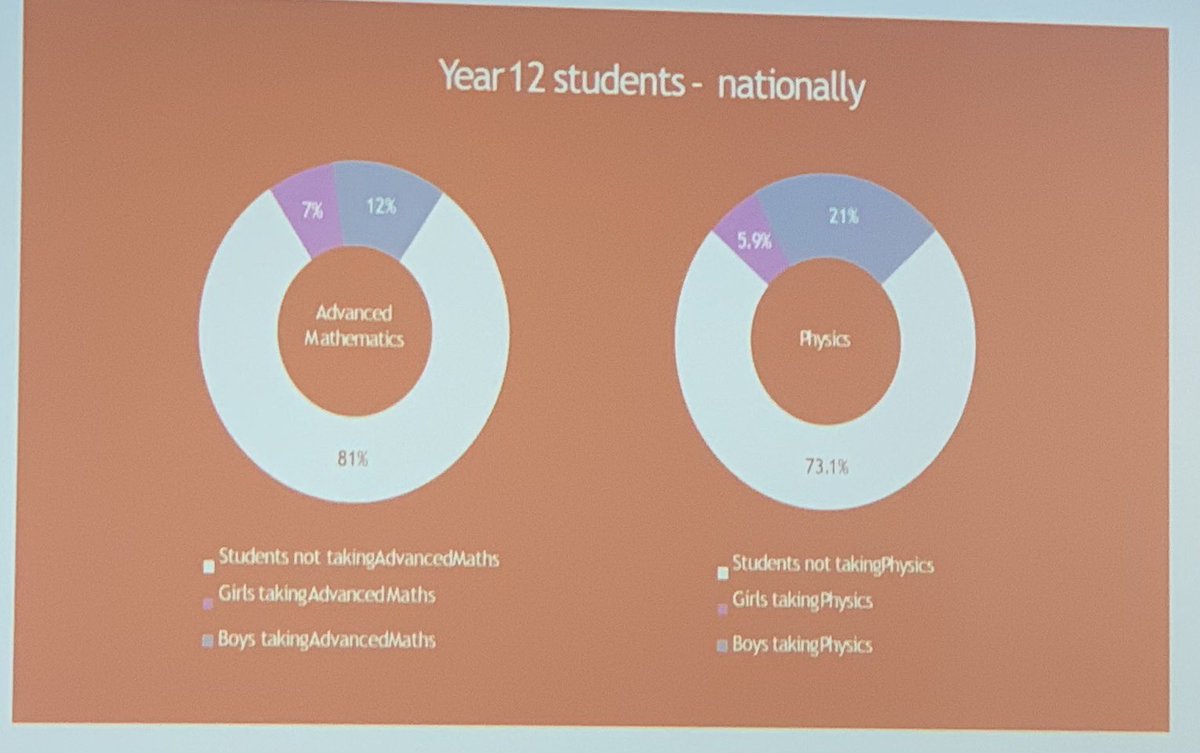

Cocreation of curricula between industry and education providers needed.

Test Labs: 6 unis now in national 4.0 test lab network. Engaging SMEs with these is critical for impact.

37% of advanced mfg have little 4.0 engagement

We’re trying for signposts, capacity building, priorities for new skills and practices - not a blueprint. I remember industry 3.0 - computerization - implementation was similar across plants. 4.0 skills more bespoke

4.0 success will require holiday, collaboration, bravery, owning failures as well as successes, trust and intellectual ferment.

75% of employers are having difficulty recruiting the right people today. This risks growing as our skills needs change with digitalization.

Response? Stronger upskilling/retraining agenda for existing workers;

Are our education and training systems set up for new needs? Doesn’t look like it - mostly set up long ago and not sufficiently updated. Work and education need to move closer.

Paradigm of ongoing education needs challenging with microcredentials, short courses and more.

People need to know where they can access training.

Q: collaboration arouses fears of competitors - do we have to get over this?

David: nobody knows all the answers on 4.0, must share info, can’t just rely on instructions for new pieces of kit - the innovation is how systems and biz models fit.

We can only get better from here.

When you’re speaking you’re not listening; I want to listen to industry stakeholders today.

Industry change is a continuous process, not just a set of discrete eras.

The Government is committed to growth, productivity and jobs. industry portfolio is where this comes together.

Hard to compete on cost, need to compete on value of Australian products.

Mining and Ag will continue to be important sources of opportunity, but new ones arise; 🇦🇺 space industry could grow from $9b to $12b by 2020. Goes well beyond launch.

Skills agenda is crucial to industry. Works closely with Minister Cash. Pipeline of skills is vital; STEM study is deteriorating. Industry needs to generate exciting experiences for kids.

The @The_AiGroup industry report released yesterday highlights key issues including cyber security.

Q: innovation - Australia has dropped out of global top 20 - any ideas for how to reverse?

A: drop from 20 to 22 is not far. Innovation has been frightening for some rather than energizing. Innovation happens across industry but is too perceived as online startups.

A: yes. We are committed to Industry 4. We want to bring industry, science and technology closer through collaboration.

A: often gets caught between Feds and States. Important for Cth to provide money with requirements on outcomes (eg apprentices taken on). Honestly this has had varied success so far; it needs to go much further.

Employers often say grads not job-ready.

A: no! Any engineers in the room who would like to go into politics - talk to me.

A: regional centres have big opportunities but are struggling to keep people - kids are moving. Ideas like incentives for regional apprentices are taking shape, but more to consider.

A: innovation - we are determined to lift collaboration between researchers and industry;

Skills - we need to make a big push here.